When: February 28, 2020 | 10:00 to 11:00 CET

Haas has reinvented grinding software. Resulting in a program, which participates rather than prescribing. Haas Multigrind® Horizon. As the central part of their machines. As an enabler, which helps you program, grind and reproduce your workpiece with accuracy. Intuitive and easy for programmers and machine operators to use. Capable and open to the applications of today and tomorrow.

Flexibility that only knows your limits.

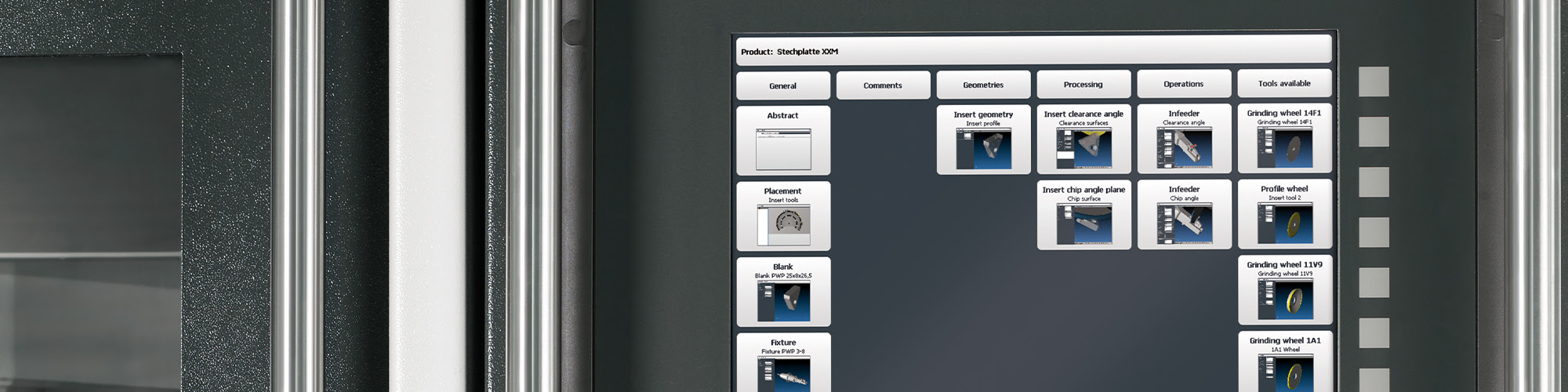

Hob cutters today, grooving insert tomorrow – our grinding software is as powerful as your imagination. Let it run free. Because with Multigrind® Horizon it is possible to combine individual workpiece elements and therefore everything. While others are still programming to determine the dimensions of the features, just enter the variables or have them read in. By combining and parameterizing them individually, they remain flexible and produce exactly the workpiece they need – faster and more precisely than before.

Make it easy for yourself.

The most intelligent software is useless as long as the operation is not as clever as the program itself. B. a uniform language, consistently run through our grinding software. Thanks to the clear user interface, you always have an overview and control over individual process components. Multigrind® Horizon gives you direct feedback when entering parameters. This enables easy and immediate intervention in the machining process instead of at the end as usual.

Always up to date.

Quarterly software releases keep your software up to date. Because Multigrind® Horizon is constantly being developed in order to have the solution for tomorrow ready today. With these updates, you can easily update your software yourself. As part of an additional service contract, we analyze and fix problems together at any time.

Everything in view, even the invisible.

The digital twin is the virtual image of the machine, workpiece and production – and has always been standard with us. Only those who know what is going to be in control. The twin shows you everything. Also what you can’t see otherwise: e.g. B. all acting forces, accelerations and deformations inside the machine. This optimizes your manufacturing process, increases quality and your competitiveness.

Accurate as usual.

No matter how often a grinding process is repeated, the result always remains within the tolerance range. Even if the general conditions change, e.g. due to temperature fluctuations. Because software, workpiece and machine are in constant dialogue with each other, deviations in the abrasive are eliminated in good time. The closed loop process enables maximum precision in production in series or batch sizes. In short: Horizon sustainably increases and secures your product quality.

A new dimension in visualization.

Thanks to ray tracing, simulation becomes visualization with maximum accuracy. Because Multigrind® Styx is the first display software to show grinding processes and workpiece data in advance. Pixel-precise and without triangulation – even with highly complex objects such as snails and rasps. Multigrind® Styx is an integrated, cloud-based component of our grinding software with more performance and less computing power.

As Haas always make Multigrind® Horizon a little bit better, the release is coming soon.

Haas invites you to a webinar on February 28th 2020 from 10:00 to 11:00 CET.

Access to the webinar is provided HERE.