The Southern Polytechnic College of Engineering and Engineering Technology at Kennesaw State University (KSU) provides high-quality engineering degrees with education led by industry-expert faculty in the university’s state-of-the-art facilities. As the second-largest engineering college in Georgia, the institution serves more than 4,500 students, offering 20 undergraduate and graduate engineering degrees and engineering technology degrees.

The Southern Polytechnic College of Engineering and Engineering Technology at Kennesaw State University (KSU) provides high-quality engineering degrees with education led by industry-expert faculty in the university’s state-of-the-art facilities. As the second-largest engineering college in Georgia, the institution serves more than 4,500 students, offering 20 undergraduate and graduate engineering degrees and engineering technology degrees.

The college offers a bachelor’s degree in Mechatronics Engineering that combines practical skills from mechanical engineering, electrical engineering and computer science. Graduates will be well-skilled in the hands-on application of robotic technology, and can select from a wide spectrum of industries for career choices. The mechatronics degree program seeks to produce graduates who can pursue registration as professional engineers, careers in mechatronics engineering or graduate education. The mechatronics degree program has close to 500 students.

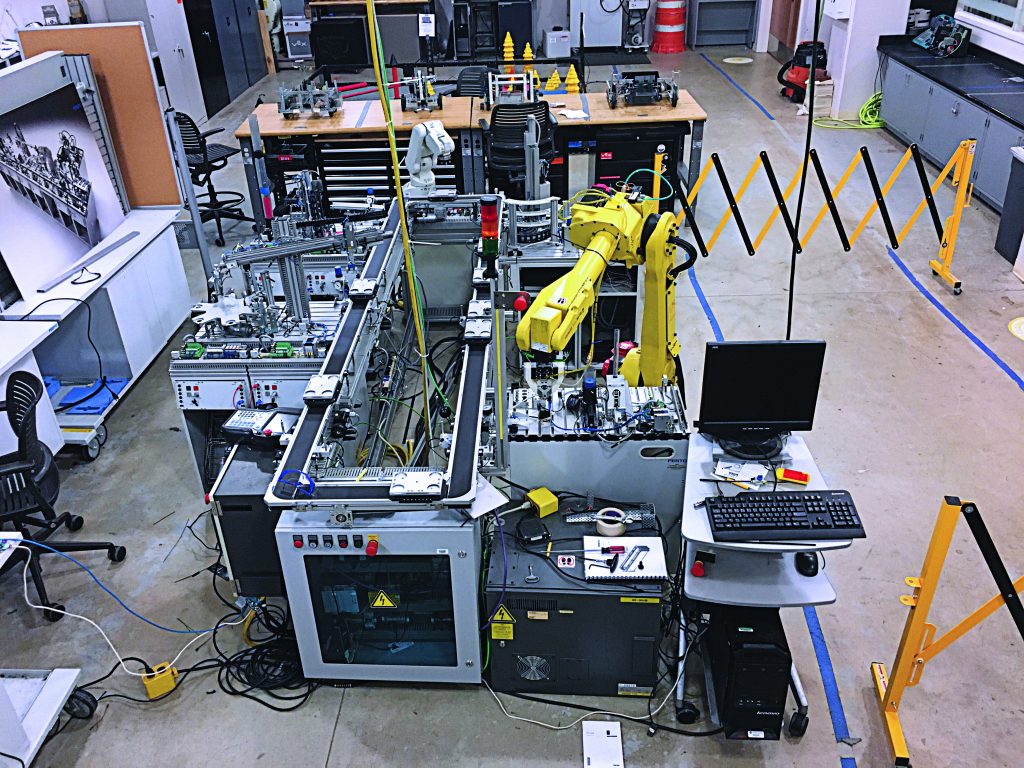

One of the elective courses in the mechatronics degree program is a senior-level course in Digital Manufacturing, which is also open to students in the Mechanical Engineering and Mechanical Engineering Technology degree programs. The laboratory for the course is located in the Kennesaw State University Technology Center, and includes an integrated manufacturing system with two Kawasaki robots and a Vanderlande conveyor system. The equipment is fully synchronized using Siemens instruments, controls and Totally Integrated Automation (TIA) Portal.

Leading-Edge Digital Manufacturing Technology

To equip students of the Digital Manufacturing course with leading-edge technologies, the Mechatronics Engineering department selected the Process Simulate solution in the Tecnomatix® portfolio of digital manufacturing software from Siemens PLM Software. In the spring of 2018, 20 students in the course implemented digital manufacturing technologies using Process Simulate software. Professor David Guerra- Zubiaga, assistant professor of mechatronics engineering at KSU, evaluated other digital manufacturing systems, but made the decision for Tecnomatix after attending a Siemens PLM Software training course on Process Simulate in robotics simulation.

“Strategically, KSU is using Tecnomatix in the Mechatronics Engineering curricula to introduce Siemens digital manufacturing concepts,” says Dr. Guerra-Zubiaga. “We expect that other engineering programs could use this platform. A challenge is showing the potential of the software not only in the Mechatronics Engineering program, but also in other academic programs. It takes time to create good case studies that demonstrate this potential, but we are on the right track.”

Students Build Digital Twins Of Integrated Manufacturing Systems

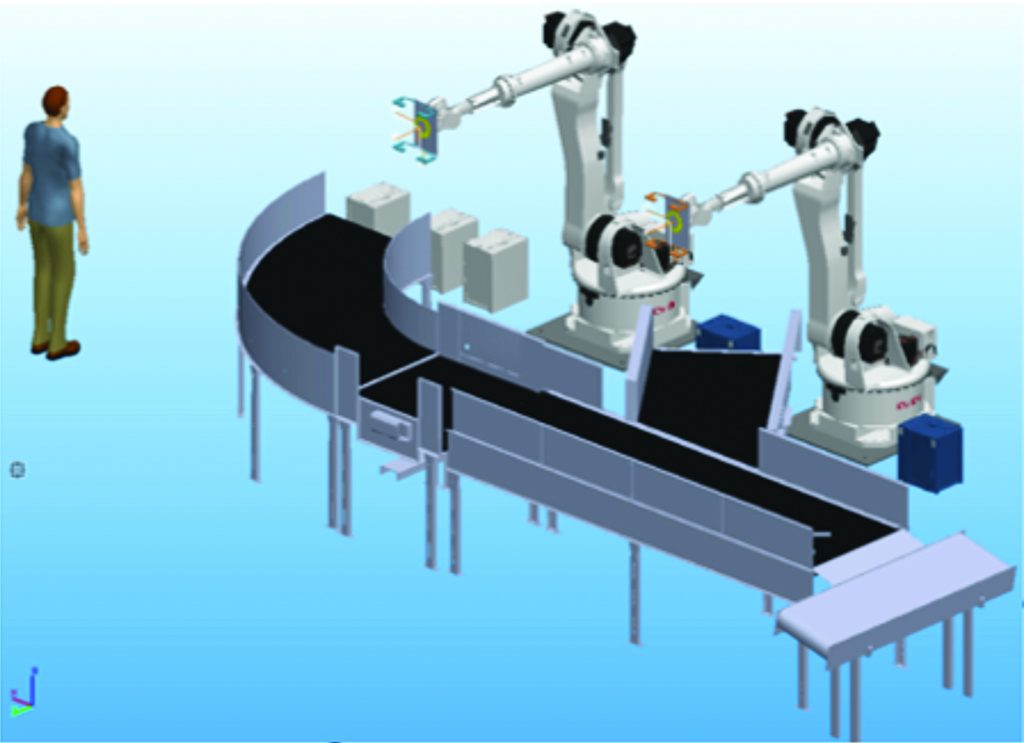

Students in the Digital Manufacturing class use Process Simulate to perform virtual simulations with virtual prototypes – digital twins – that replicate the real integrated manufacturing system. The students are organized into teams that work in a project-oriented learning environment to implement simulations of three integrated manufacturing systems, following course case studies. The handson approach enables students to understand and apply advanced manufacturing concepts including the Internet of Things, digital twins, collaborative robotics and Industry 4.0.

“Managing the learning curves with undergraduate students is very challenging because of the high rotation rate and their mobility,” says Dr. Guerra-Zubiaga. “Implementing high-quality case studies is important. We can potentially gain attention from industry through academic projects.”

Support from Siemens

A key aspect of the successful implementation of Tecnomatix at KSU was support from Siemens. “We used Siemens Global Technical Access Center support services as we moved through the implementation,” Dr. Guerra-Zubiaga explains. “Siemens also provided a grant to KSU supporting mechatronics and advanced manufacturing education.”

Siemens is a member of the Industry Advisory Board, providing support, guidance and advice on the mission and goals of the Mechatronics Engineering department and promoting collaboration between academia and industry. Siemens USA also funds an annual scholarship for undergraduate students seeking the bachelor’s degree in Mechatronics Engineering.

Benefits For Faculty, Students And The University

The use of Siemens PLM Software solutions at KSU has yielded benefits for faculty, students and the university. Professors used Tecnomatix software to help prepare research papers that were presented at the American Society of Mechanical Engineers (ASME) International Mechanical Engineering Congress and Exposition (IMECE) in 2017.

In addition to the role of Process Simulate as a foundation for the Digital Manufacturing class, students of the class used the software in preparing five papers that have been accepted for ASME IMECE 2018, and are collaborating with professors at universities in China, Mexico, Turkey and Switzerland to create the final versions of the papers.

In summer 2018, KSU welcomed a student from Fribourg University in Switzerland who was preparing a bachelor thesis implementing the Siemens software. The student worked with KSU students on a project exploring methods and procedures for implementing product lifecycle management (PLM) tools, under the supervision of Dr. Guerra-Zubiaga and Dr. Donato Laurent at Fribourg University.

“We will continue to conduct and publish research using Siemens PLM Software solutions,” says Dr. Guerra-Zubiaga. “It has been very beneficial to get to know the digital manufacturing experts at Siemens, as well as other universities using the technology. We have also gained a deeper understanding of the skills students will need in industry. A next step is continuing exploring the digital twin and Industry 4.0 aspects connecting Siemens Tecnomatix software and TIA Portal for implementing virtual commissioning in an integrated manufacturing system.”

About Siemens PLM

Siemens PLM Software, a business unit of the Siemens Digital Factory Division, is a leading global provider of software solutions to drive the digital transformation of industry, creating new opportunities for manufacturers to realize innovation. With headquarters in Plano, Texas, and over 140,000 customers worldwide, Siemens PLM Software works with companies of all sizes to transform the way ideas come to life, the way products are realized, and the way products and assets in operation are used and understood.

About Siemens AG

Siemens AG (Berlin and Munich) is a global technology powerhouse that has stood for engineering excellence, innovation, quality, reliability and internationality for 170 years. The company is active around the globe, focusing on the areas of electrification, automation and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of efficient power generation and power transmission solutions and a pioneer in infrastructure solutions as well as automation, drive and software solutions for industry. The company is also a leading provider of medical imaging equipment – such as computed tomography and magnetic resonance imaging systems – and a leader in laboratory diagnostics as well as clinical IT. In fiscal 2017, which ended on September 30, 2017, Siemens generated revenue of €83.0 billion and net income of €6.2 billion. At the end of September 2017, the company had around 377,000 employees worldwide.