Quiet, Low Vibration and Energy-Saving: High-Pressure Plunger Pumps with New Drive Technology

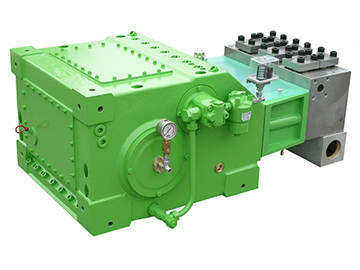

KAMAT has fundamentally revised the mechanical powertrain of its triplex plunger pumps for pressures up to 3500 bar. As a result: They now operate much quieter, and the drive systems consume less energy – in particular in combination with a variable speed drive.

Never stop striving for perfection: According to this principle, KAMAT has developed a new powertrain for its high-pressure plunger pumps and has introduced these drives systems successively in all series.

The reason for this was the wish of some users e.g. in the mining industry to find a low-noise high-pressure pump. This requirement was difficult to meet with the proven drive concepts of KAMAT pumps, because the crankshaft – which moves the plunger via crossheads – had to be asymmetrical, in order to accommodate them in the previously undivided housing. The asymmetry resulted in much stronger vibrations, which made it difficult to achieve acoustic decoupling using damping elements due to the vibrations.

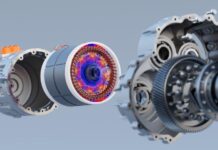

The KAMAT designers then developed split gear cases, where a symmetrically balanced crankshaft takes over the power transmission between the drive and the plunger. A newly designed double helical gearing also contributes to the increased running smoothness and reduced noise of the pumps. The gearboxes are from our own production, as KAMAT already took over the former supplier of driveline components in 1983, and since then has been able to maintain the corresponding expertise in-house.

The new design is now used in the triplex pumps with power classes ranging from 80 to 800 kW. It also forms the basis for the drive design of the quintuplex pumps that KAMAT has now developed for serial production, providing significant cost savings from the point of view of the large volume flow user.

Furthermore, the mechanical part of the drive system satisfies the prerequisite for a variable speed control of pumps, which is part of the core competencies of KAMAT and allows plunger pumps to be operated in an energy-efficient and demand-oriented way.

The new powertrain increases the energy efficiency and smooth running of high-pressure plunger pumps and reduces the noise level.

Compact power transmission – tailored for use in high pressure pumps: the transmissions used in KAMAT pumps come from our own development and production.

About KAMAT

Since more than 40 years, KAMAT GmbH with its head office in Witten, Germany, is worldwide leading system-supplier for high-pressure technology. The product range includes high-pressure pumps and pump systems, hydraulic valves, rotating joints as well as accessories for the pressure transport of different liquids in process technology, water hydraulics and high-pressure water jet technology for working pressures up to 3500 bar and power inputs up to 800 kW per pump.

Besides the standard products of pumps and systems, KAMAT designs and supplies customized units and systems, especially based on the requirements of the respective application. With a team of highly qualified developers, the innovation leader continuously further develops the high-pressure technology and sets worldwide new standards. Main customers are service contractors in all industrial sectors but as well direct customers in the chemical, petro-chemical and steel industry, shipbuilding, process engineering, energy as well as surface and underground mining. KAMAT is worldwide market-leader for special pumps for underground coal mining.

The company has been founded in 1974 as the European branch of a big American pump manufacturer and sold in 1979 to the Managing Director at that time, Dipl.-Ing. Karl Sprakel. Today KAMAT, managed by Dipl.-Ing. Jan Sprakel and Dr.-Ing. Andreas Wahl, employs more than 100 people. Partners in more than fifty countries on all continents ensure distinguished customer service all over the world. More than 80 % of the turnover is achieved abroad.

For more information, visit www.kamat.de.