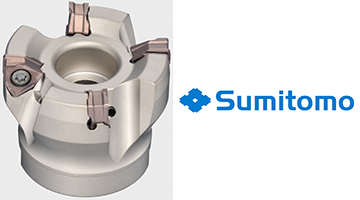

New from Sumitomo Electric Carbide Inc., the DFC Double-Sided 90º Milling Cutter is engineered for exceptional precision and efficiency.

The high toughness and special shape of the DFC six-edge insert ensure long-term, stable cutting and high efficiency machining with high feed rates. Cutting edges are optimized to provide excellent surface finishes.

Low cutting forces and high wear resistance of Sumitomo’s DFC result in a long tool life. Machining accuracy is enhanced through the separation of the insert contact areas and cutting edges. In addition, a double-sided insert design reduces costs.

Recommended insert grades for steel include ACP200 and ACP300. For stainless steel applications, ACM200 insert grades are recommended and for cast iron applications, ACK200 and ACK300 insert grades are recommended.

The DFC is available in 1” to 8” in standard, fine pitch and extra-fine pitch styles for a variety of applications. Maximum depth of cut is 6mm.

For a limited time, Sumitomo is offering special savings on DFC Cutters, including BOGO, kit prices, free cutter with the purchase of inserts, and purchase of 30 inserts get 10 free. Offer ends March 31, 2016.

For more information, contact Sumitomo Electric Carbide, Inc., 1001 Business Center Drive, Mount Prospect, IL 60056, Phone: (800) 950-5202, Fax: (847) 635-9335, e-mail: info@sumicarbide.com, or visit sumicarbide.com/milling_dfc.htm.

The History of Sumitomo Electric Industries

The Sumitomo business was started in Kyoto, the historic capital city of Japan, nearly 400 years ago by Masatomo Sumitomo (1585-1652) and Riemon Soga (1572-1636).

Masatomo is regarded as the spiritual founder of the Sumitomo Group. Following an early career in the Buddhist priesthood, he established a shop in Kyoto that sold medicines and books. In accordance with the custom of his time, Masatomo produced written teachings for his household and disciples. One volume of these, which provided advice on the conduct of commercial activity, has come to be known as the “Founder’s Precepts” and is the basis of code of conduct, still today, for the Sumitomo Group of companies.

Riemon, who was a disciple and brother-in-law of Masamoto, was the technological pioneer who set the Sumitomo business on the path to commercial success. Having studied copper refining, Riemon established the Izumia copper business in Kyoto in 1590. Until the late 16th century, Japanese copper merchants did not possess the technology to extract the silver contained in copper ore, which compelled them to export the ore with the silver intact. By learning and perfecting Western smelting methods, Riemon engineered a revolution in Japanese copper refining. The Sumitomo business was continued by Riemon’s eldest son, Tomomochi (1607-1662), who entered the Sumitomo family through his marriage to Masatomo’s daughter. Tomomochi moved the copper smelting business to Osaka, Japan’s commercial capital at the time.

One of the epoch making events in the early days of the Sumitomo family was the 1690 opening of the Besshi Copper Mine on the island of Shikoku, across the Seto Inland Sea from Osaka. The Besshi Copper Mine was extremely productive and profitable, right up to the early 20th century. Consequently, it played a pivotal role in the birth of many core companies of the Sumitomo Group today. In 1891, Sumitomo formulated its Business Principles, which are based upon the “Founder’s Precept” by Masatomo.