Premiere at K 2019:

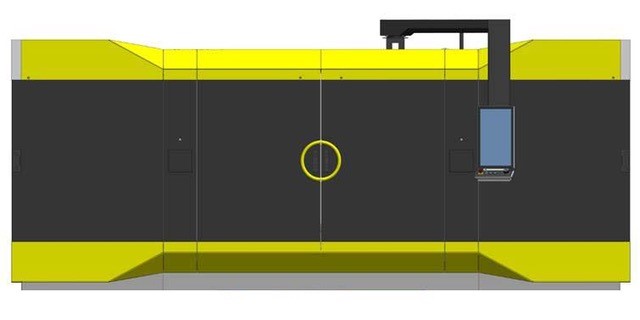

Newly designed blow moulding machine for packaging, “Concept 808”, with many innovative features:

- New, functional machine design

- Magnetic quick mould change system

- High-output and Energy-efficient Extrusion Package

- New generation Bekum Controls 8.0

- Regrind processing in line with the circular economy

Whoever wants to be informed about industry trends, innovations and hot topics at K 2019 won’t pass Bekum by. Bekum is heralding the future of blow moulding with the “Concept 808” machine study.

New Design and Improved Functionality

At first glance, all observers will note the modern design of the machine’s cladding.

The design is eye-catching with its aesthetics, modern colors and shape and is characterized by still more functionality and improved ergonomics. Among the practical extras are, for example, the large-scale safety gates and integrated variable color LED signal lights that indicate operating status and simplify required maintenance.

Only 15 Minutes for a Mould Change

One of the excellent features is the optional magnetic quick mould change system. With this, mould change-over is accomplished in 15 minutes per clamping unit – without tools or a special mould cart. Particularly Noteworthy is the simple and easy to operate magnetic blow pin quick change system. Moulds and blow pins are always changed from the front side of the machine.

High-output and Energy-efficient Extrusion Package

A well-tuned high-output extrusion system essentially ensures product quality. The new generation of high-output extruders of the future packaging machine line distinguish themselves through processability, high maximum throughput, and excellent melt homogeneity. Bekum places particular importance on energy efficiency when developing extruders. Extruders are the main consumers of energy in any extrusion blow moulding machine. Bekum extruders use energy efficient motors and drives, which are important to achieve high energy efficiency. (Class 10 as called out in EUROMAP 46.1).

Bekum extrusion heads in either mono- or multi-layer technology are designed to achieve precise flow guidance, short color change times and uniform wall thickness throughout the article for all extrusion blow moldable plastics.

Bekum Control 8.0 – New Operator Panel with New Visualization

The modern machine design of the future machine series will be enhanced via a portrait-oriented, generously dimensioned 24 inch operator panel and a new, intuitive touchscreen called Bekum Control 8.0. Visualization of throughput values and energy consumption on the multi-touch operation panel is provided as well as the display of power, water, air consumption, and the pressures of all supplies process utilities.

Remote on-line service, as emphasized by Industry 4.0, has been available from Bekum for many years. With permission of the owner, Bekum service technicians can log in to machine controls and carry out function tests and perform software updates.

Circular Economy – Regrind Processing on the Show Machine

Bekum is engaged in the circular economy and, with its Bekum 3-layer heads, offers a solution for costs-effective recycling of single-origin PE of PP plastic scrap. Thanks to Bekum’s tri-extrusion technology, recycled material (PCR) can be embedded between layers of virgin plastic materials. The use of PCR in the middle layer can also permit a cost-reduction in the manufacture of containers. Bekum is presenting the Concept 808 show machine with a multi-cavity three-layer application.

Bekum at K 2019: Hall 14, Booth C03

About Bekum

Pioneer and Trendsetter in Blow Moulding Technology – Founded in Berlin in 1959, Bekum Maschinenfabriken GmbH is one of the world’s leading manufacturers of extrusion blow moulding machines.

Founder Gottfried Mehnert conceived the name Bekum as the acronym (Berliner Kunststoff Maschinen).

The company began to flourish in its founding year with the development of the world’s first neck-rim calibration. Numerous innovations and patents followed, confirming that Bekum, with its innovative and customer-oriented machinery solutions, has always been ahead of its time – and remains so to this day.

When innovative and economical machinery solutions with high productivity for individual packaging requirements of hollow packaging are in demand, then Bekum, with 60 years of experience in blow-moulding technology, is the first choice worldwide.

Product Range and Applications in Food and Non-food

With future-oriented and reliable production processes and fully electric, as well as hydraulic machinery for the commercial production of blow moulded containers ranging from 5 ml to 3000 l, Bekum offers everything for plastic packaging from one source.

Philosophy of the Company

Building and maintaining long-term relationships with market partners through future-oriented, predictable company policy determine the actions of the first and second generation of the family, represented by Michael Mehnert. This strategy ensures the jobs of dedicated and experienced staff. The preservation of traditional structures, an established network of partners and far-sighted adaptation to change form the basis for continuous development and inspiration for the company in the interest of partners, customers and employees.

Innovation and Technology

Process reliability, availability, efficiency and sophisticated design characterise the high standard of Bekum production lines for blow moulding. Bekum contributes the expertise that has grown based on these references, associated with various patents in blow moulding, to the fulfilment of every customer requirement.

The level of process design is key for process reliability, reproducibility, parts quality and cost-efficiency. A high-quality production line for extrusion blow moulding, consisting of machine, die and automation which is impressive in terms of speed, wear resistance, availability, process reliability and stability alike, is critical for return on investment (ROI) and the level of added value.

Facts and figures

With 18,000 machines delivered and installed worldwide – about half of them still in use – the Bekum Group has achieved by far the largest production of blow moulding machines of any brand.

The Bekum Group serves approximately 100 countries around the world directly or through representatives.

Today, 350 employees work for the Bekum group worldwide at three locations in Europe and in the US (Berlin (Germany), Traismauer (Austria) und Williamston (USA)).

Our Technology – Your Success

Bekum Maschinenfabriken GmbH

Kitzingstraße 15/19

12277 Berlin

Deutschland

P: +49 (0)30 7490-0

F: +49 (0)30 7490-2441