Rollomatic is exhibiting at the IMTS 2022 (International Manufacturing Technology Show) in September 2022 in Chicago, IL.

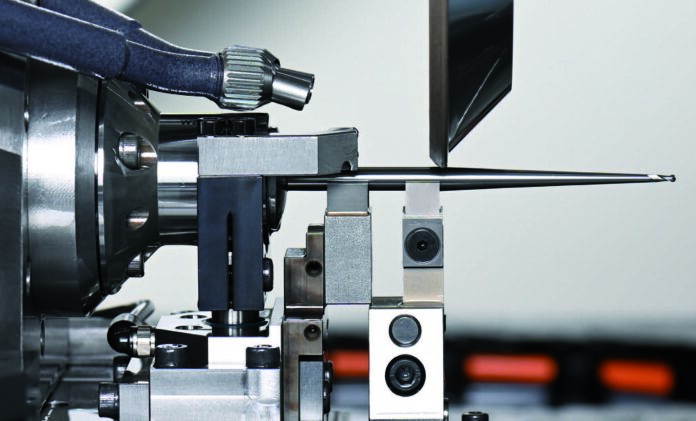

Rollomatic maintains its global leadership position in the field of multi‐axis CNC grinding by spotlighting the new hybrid model GrindSmart® 660XW for combination grinding of tool geometries as well as peel grinding for neck, plunge grinding or other pre‐fluting or post‐fluting operations.

The new GrindSmart 660XW is a 6‐axis tool and peel grinding machine. It allows the user to utilize cost‐effective and advanced lean manufacturing principles; termed as “Ultra‐Lean Grinding Process”. The machine includes a 6‐position wheel changer and linear motors on all axes.

- Workhead: It features a traveling high‐speed workhead. Peel grinding for blank preparation and neck grinding are included in the same chucking. RPM is up to 3,000.

- Peel grinding: Blank preparation for common‐shank rotary cutting tools, neck grinding for long‐reach mold & die endmills and plunge grinding operations can be performed.

- Steady rest: This machine includes an innovative steady rest systems designed for grinding endmills as well as for drill point grinding.

- Spindle motor: The grinding spindle is synchronous and is rated 20 hp.

- Thermal stability and Cpk process capability index: The thermal stability is exceptionally good due to an innovative 6‐axis design and double‐skin coolant enclosure. Field tests have demonstrated an unusually high Cpk process capability index for any tool grinding machine.

- Grinding range: From micro‐size range to 1/2” (12.7 mm).

About the Rollomatic Inc.

Rollomatic Inc., located in Mundelein, Illinois, is a subsidiary of Rollomatic SA, a privately‐owned Swiss company established since 1989 in Le Landeron, Switzerland. The US Headquarter was launched in 1994 to provide local customer service and support throughout the U.S., Mexico and Canada.

This location features a 29,000 sq. ft. building with a showroom and training area as well as warehouse and engineering offices. Our showroom provides an ideal atmosphere for machine demos, software training and test grinding, while offering an opportunity to explore the latest Rollomatic offerings.

Rollomatic is looking to the future with its partners such as the EPFL (Swiss Technical University in research, teaching and innovation) so it can be right at the center of the innovations and in‐depth discussions shaping the Fourth Industrial Revolution. True to its Swiss origins, the company operates at the highest level of precision and offers 100% Swiss‐built products and services. Rollomatic is in constant pursuit of excellence in quality and accuracy.