Because machine tools constantly cut and grind away material at high RPMs to shape a workpiece, carbide cutting tools are often used instead of hardened steel to retain a sharp cutting edge and lengthen tool life. However, when highly-abrasive materials such as CFRP/GFRP/sandwich materials, graphite, Al alloys and ceramics are machined, even carbide tools can be prone to rapid wear.

Because machine tools constantly cut and grind away material at high RPMs to shape a workpiece, carbide cutting tools are often used instead of hardened steel to retain a sharp cutting edge and lengthen tool life. However, when highly-abrasive materials such as CFRP/GFRP/sandwich materials, graphite, Al alloys and ceramics are machined, even carbide tools can be prone to rapid wear.

In such cases, further hardening cutting tools with a variety of specialty coatings can significantly prolong wear resistance and service life.

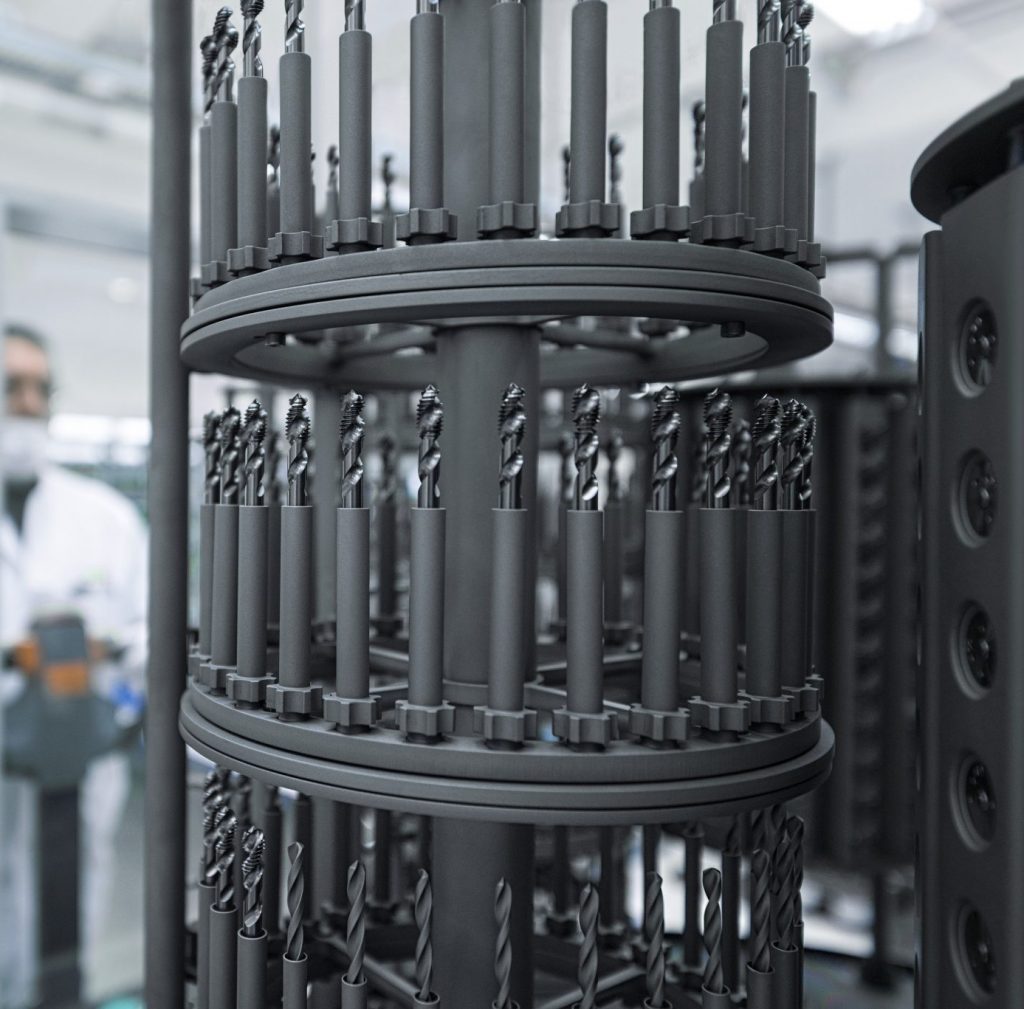

These coatings, applied to machine tools such as taps, reamers, end mills, drills, inserts, counter sinks and other cutting tools, come in a variety of styles from physical vapor deposition (PVD) coatings up to proprietary diamond coatings.

Need for Greater Abrasion Protection

In a growing number of industries including automotive and aerospace, manufacturers are continuing to place more emphasis on design and weight reduction. Subsequently, designers are increasingly using composite fiber reinforced plastics in many parts. However, these composites are exceedingly rough on cutting tools.

“The problem with the carbon and graphite fibers is that they are very high-strength and extremely abrasive,” says Volker Derflinger, a senior manager for Oerlikon Balzers, a company that has been producing specialized coatings for components and tools for more than 30 years. “For cutting tools to withstand heavy wear, a specialty coating with a very high resistance to abrasion is needed.”

In industries like automotive that require stronger, lighter materials, aluminum silicon alloys are also used. However, the higher the silicon content, the more abrasive the material.

PVD Coatings

One alternative that is increasingly being utilized in these industries are strong, non-hazardous, Physical Vapor Deposition (PVD) coatings. PVD describes a variety of vacuum deposition methods that can be used to produce thin coatings. PVD is typically used to coat tools and components at relatively low coating temperatures of 150-500 °C, which avoid altering the fundamental material properties.

Among the PVD options are several carbon-based coatings available that provide a unique combination of extreme surface hardness and low friction coefficient properties. One example, BALINIT Hard Carbon by Oerlikon Balzers is used for the machining of non-ferrous materials, including aluminum alloys with up to 12 percent silicon content (AlSi-12).

“The Hard Carbon coating works on CFRP and GFRP, but only when the fiber content is on the lower side,” explains Derflinger. “The more fiber content, the more abrasive the material is and then you need an even harder coating.”

“The Hard Carbon coating works on CFRP and GFRP, but only when the fiber content is on the lower side,” explains Derflinger. “The more fiber content, the more abrasive the material is and then you need an even harder coating.”

The BALINIT Hard Carbon coating is thin, smooth, and has high hardness (40-50 GPa), making it well suited for applications that require superior wear protection. In addition, the thin, smooth application helps to maintain sharper cutting edges.

Diamond Coatings

When carbon content in composites or silicon content in aluminum alloys becomes too high, cutting tools typically require a diamond coating to prevent wear.

Traditionally, polycrystalline diamond (PCD) cutting tools have been utilized in such instances. PCD is a composite of diamond particles sintered together with a metallic binder.

As a cutting tool material, PCD has good wear resistance but it lacks chemical stability at high temperatures and dissolves easily in iron. So, PCD tools are usually limited to materials such as high-silicon aluminum, metal matrix composites (MMC) and CFRPs.

In addition, PCD tools are geometrically limited in structure, and may be too rough or unrefined for the optimal machining of the wide range of non-ferrous materials. Finally, PCD cutting tools can also be quite expensive.

As an alternative, plasma-assisted chemical vapor deposition (PACVD) can be used to apply crystalline diamond structures in varying thickness and roughness. This can be highly advantageous for machining fiber-reinforce plastics, graphite, non-ferrous materials and ceramics.

With the PACVD coating process, a carbide cutting tool is sequentially coated by two different gasses in a heated vacuum container assisted by plasma. Each alternating cycle that built the atomic layer on the surface and the number of cycles thus controls the thickness of the final coating.

With the PACVD coating process, a carbide cutting tool is sequentially coated by two different gasses in a heated vacuum container assisted by plasma. Each alternating cycle that built the atomic layer on the surface and the number of cycles thus controls the thickness of the final coating.

“As a cost effective, high-performance alternative, specialized PACVD-based diamond coatings can increase the service life of the tool,” says Derflinger.

In terms of satisfying such qualities, BALINIT Diamond Micro and Nano coatings are examples of PACVD-based diamond coatings formulated specific to the needs of a wide range of highly-abrasive, non-ferrous materials.

The Bottom Line

Manufacturers that take advantage of the superior capabilities of high-performance Hard Carbon PVD and Diamond PACVD coatings will significantly harden carbide cutting tools and improve part quality. This will enhance production and tool service life, which also improves the bottom line. “Even if the cutting tool is expensive, you can put a hard coating on it and you will get a much better performance out of it,” says Derflinger. “That is why in the future more and more tools are going to have specialty coatings.”

Oerlikon Balzers

P: (248) 409-5900 ext. 2121 | 248-884-9118

logan.walz@oerlikon.com