Additive Manufacturing, or 3D printing, has evolved from prototyping with basic materials and equipment to producing low tolerance components with limited use to additive manufacturing as we know it today, that is, a highly complex, high accuracy production technology which is rapidly impacting a number of industries in which it competes as a viable alternative to traditional chip-cutting or injection molding methods. The evolution of hardware and software is quickly removing barriers and enabling machine builders and machine users to adopt additive manufacturing technologies in their factories and on their shop floors. It represents a significant development on the road to digitalization.

Market Opportunities

Additive Manufacturing is relevant in a wide range of industrial applications including machine building, chemicals, power and utilities, aerospace, automotive, mobility, oil and gas, robotics, medical, tooling, water and wastewater, wind, smart buildings, marine, electronics and more. Every one of these industries has applications for additive manufacturing — and not tomorrow, today.

Additive manufacturing opens myriad opportunities for manufacturers. Companies can reimagine their products with reduced weight and material consumption. They can actually realize a digital transition from scan to part. Further, they can rethink their business or reinvent their manufacturing. Product transformation happens by moving from conventional designs to a design specifically for additive manufacturing. Other realities quickly become apparent, as well, including the ability to produce one-offs in a practical and cost-effective manner, maintain zero inventory in certain industries with on-demand production, adopt a design-anywhere, print-anywhere mindset and accelerate innovation cycles. Finally, a company can eliminate molds, castings and tooling, eliminate or drastically reduce assembly processes, reduce supply chains and move to a flexible, low-volume production landscape at workable margins.

A very practical example of how additive manufacturing may soon be commonly used in our homes, would be a handle breaking on a kitchen appliance. Normal practice would be to contact the manufacturer and wait for a replacement handle to be shipped, but at some point, in the not too distant future, we’ll be able to go online and download the model for the handle at the manufacturer’s website. We could then either print it in our home on our own 3D printer or go to a local print shop and have it made. The product would be identical to the factory design.

A Reality Today

Another key advantage to 3D printing is the ability to implement rapid iterations in form, fit and function, when developing products. Products can be individualized and personalized in ways that were not previously possible. For example, Siemens has worked with a German automobile manufacturer to completely individualize vehicles for their owners. A customer can buy a new car and, through the company’s website, customize the interior dash panel with the wording or pictures they want on them and then have it 3D printed automatically in Germany to personalize their new vehicle. Can you remember when the “volume in automotive” was considered a major roadblock to the implementation of additive in that world? Seems like just yesterday.

Automotive manufacturers have suppliers all over the world. For example, an American automobile manufacturer has approximately 100,000 suppliers providing components worldwide. With additive manufacturing, they can now design anywhere and print anywhere, without the need to design and manufacture in the same location. Additive also offers the freedom of printers running mostly unmanned.

Additive manufacturing has accelerated innovation by taking it to the next level. With 3D printing, a manufacturer can quickly get the part in their hands and can see it in form, fit and function modes. They can make an adaptation and quickly print it again. Additive has reinvented manufacturing by eliminating moldings, castings and tooling, in most applications.

Case in Point-Aerospace

Another recent example is an aviation fuel injector. This project took several years but started with 21 individual machined cast and fabricated components that were welded and braced together to create a fuel nozzle and injector. Today, that fuel injector is printed out as one component on an additive manufacturing machine. It simplifies the assembly process, radically improves quality, reduces inventory and changes the supply chain in fundamental ways. This is an excellent example of additive acting as a “disruptive” technology. A poor choice of word, perhaps, because of its pejorative nature. However, that is precisely the description which fits, as additive impacts the entire process of part concept, design, manufacture and assembly, whether that part is injection molded plastic, cast base metal or machined superalloy.

The additive process started out very complex, requiring many steps that occurred in a silo mentality, with multiple types of software and individual workstations for design, simulation, print prep, actual additive manufacturing, heat treat and finishing/inspection. Recent advances in digitalization today allow a fully digital and far more cost-effective, end-to-end solution.

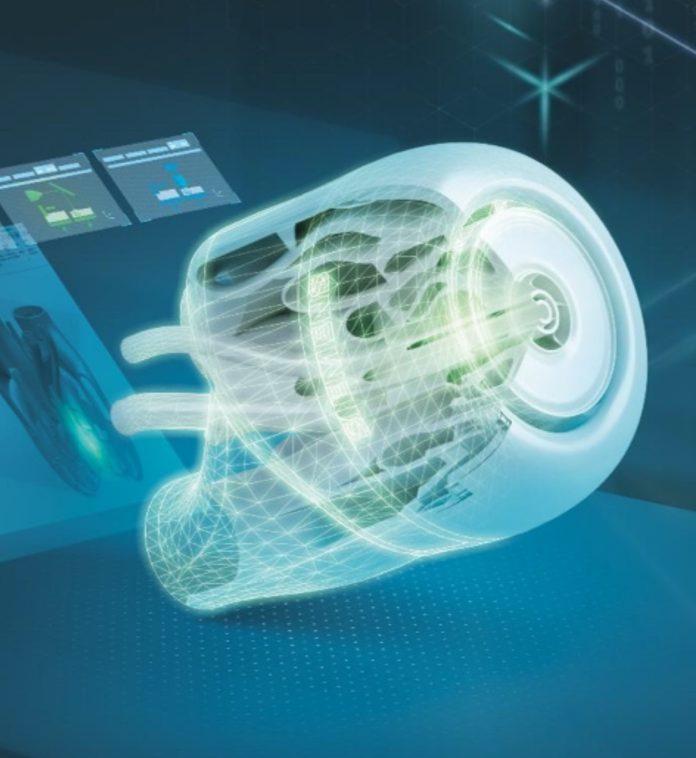

Starting with the Virtual Product, or the Digital Twin, then the Virtual Production, which is the Digital Twin Production, to the Real Automation, which is the real machine doing its work. A closed loop digital chain can link all these functions together and keep them in one solid package. It can also collect performance data at every step, realize the data, optimize it and have it resident on one collaboration platform with a solid industrial ring of security. This model provides a great value to the manufacturer by taking real product feedback performance data and feeding that data directly back into the original CAD model of the design. By simulating it throughout the entire process for validation, this model can be simultaneously predicting manufacturing and even assembly challenges, adjusting the design as needed to compensate.

Other Examples

Other Examples

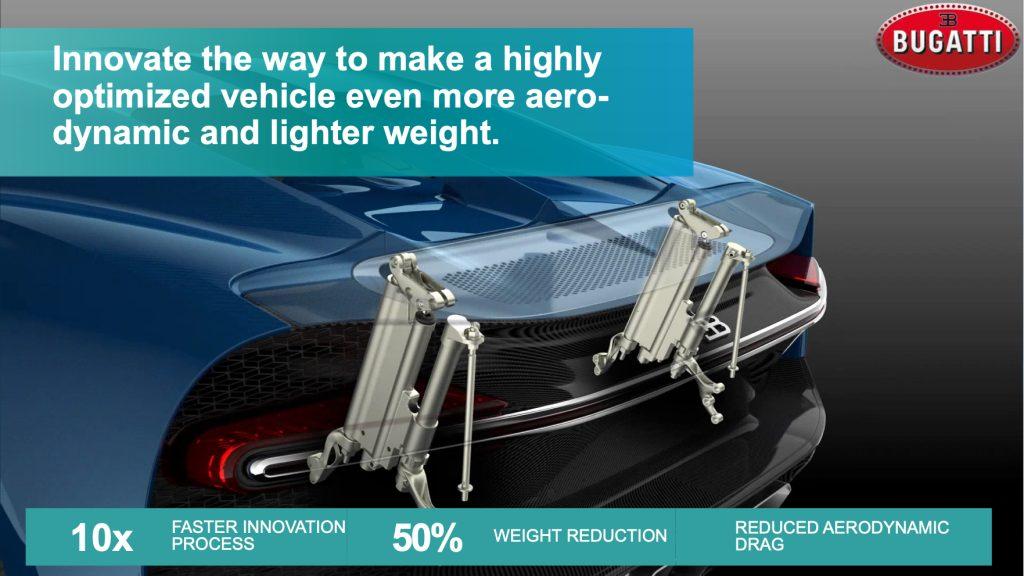

The revolutionary Bugatti Chiron…the fastest production vehicle (as of this writing) in the world. The aerodynamics and lightweighting issues on the rear braking foil achieved a 10X faster innovation, with 50% weight reduction and significantly reduced aerodynamic drag, all modeled in a virtual environment and largely produced by additive manufacturing.

The revolutionary Bugatti Chiron…the fastest production vehicle (as of this writing) in the world. The aerodynamics and lightweighting issues on the rear braking foil achieved a 10X faster innovation, with 50% weight reduction and significantly reduced aerodynamic drag, all modeled in a virtual environment and largely produced by additive manufacturing.

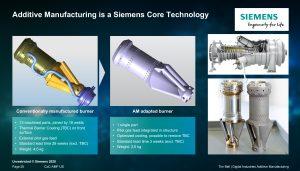

In another example, a fuel injector on a land-based power plant generator, the part count was reduced from 13 to 1, the lead time for a new design went from 26 to 3 weeks and the overall part weight reduction achieved was 22%. The project involved ways to improve a highly optimized gas turbine and move to hydrogen in the plant. Additive has many applications on legacy systems in a range of industrial and commercial applications that can prove to be a worthwhile investment today.

3D printing can innovate the way to improve machines, as well. A print head cooling duct that was designed around Computational Fluid Dynamics. HP and Siemens collaborated and used Digital Twin technology on the design and performance, then printed the part on an HP 3D machine. The engineers finally redesigned the part inside the HP machine. This resulted in the part cost being reduced by 34%, while increasing the air flow by 22% and resulted in an overall faster part development by 75%. This is an air duct, because it cools down the print heads and keeps them cool during very long build times. It had two print heads and to generatively design this, the part in the center of the slide is very fluid in its shape. Today, it would be designed around optimized flow paths for cooling, but this demonstrates how a manufacturer of 3D printers leveraged their printers with additive manufacturing on the Siemens holistic platform.

3D printing can innovate the way to improve machines, as well. A print head cooling duct that was designed around Computational Fluid Dynamics. HP and Siemens collaborated and used Digital Twin technology on the design and performance, then printed the part on an HP 3D machine. The engineers finally redesigned the part inside the HP machine. This resulted in the part cost being reduced by 34%, while increasing the air flow by 22% and resulted in an overall faster part development by 75%. This is an air duct, because it cools down the print heads and keeps them cool during very long build times. It had two print heads and to generatively design this, the part in the center of the slide is very fluid in its shape. Today, it would be designed around optimized flow paths for cooling, but this demonstrates how a manufacturer of 3D printers leveraged their printers with additive manufacturing on the Siemens holistic platform.

As further evidence of the confidence now residing in the industrial world for additive, Siemens recently installed the first 3D printed part operating in a nuclear power plant, namely, a water pump impeller replacement, where the original manufacturer had ceased operations. Through reverse engineering and the Digital Twin technology, the part was 3D printed by Siemens on a powdered metal fusion bed using Selective Laser Melting (SLM) technology. The impeller has (as of this writing) performed successfully for three years at a power plant in Slovenia.

As further evidence of the confidence now residing in the industrial world for additive, Siemens recently installed the first 3D printed part operating in a nuclear power plant, namely, a water pump impeller replacement, where the original manufacturer had ceased operations. Through reverse engineering and the Digital Twin technology, the part was 3D printed by Siemens on a powdered metal fusion bed using Selective Laser Melting (SLM) technology. The impeller has (as of this writing) performed successfully for three years at a power plant in Slovenia.

This represents the core advantages achieved through additive manufacturing on a burner. The re-design evolution of the part was done in a computer model, not on a machine, thereby achieving the results.

Making the Move

In the transition from traditional design and manufacturing to additive, in this case powder bed fusion technology, the process begins with these steps, ideally done inside a single software:

- Create generative designs and lightweight structures

- Validate designs and simulate physical behavior

- Adapt and optimize designs

- Check the printability of the part

- Next, the design of the process involves:

- Preparing the part for printing

- Predicting and compensating for thermal distortion

- Planning the removal of support structures, which is critical and often overlooked

- Planning the inspection process

- The actual production process involves:

- Utilizing full traceability and operator guidance

- Improving the machine quality and efficiency

- Fully automating the removal of powder

- Fully automating the removal of support structure

Finally, here are five action tips to speed up the utilization of Additive Manufacturing for a company — at the right place, the right level and the right pace, are listed here.

- Understand and ideate — learn about potentials and threats of additive to your company. To do it, you need to create a vision.

- Define and pilot — identify and design products. Design is key. If a component is working well, there may not be a reason to 3D print it.

- Monetize it — it must make money for your company to accept it.

- Scale it — start small and ramp up and industrialize.

- Digitalize — drive the efficiency through digitalization. Completely simulate the entire process from design through manufacture of the component digitally. Protect your knowledge through state-of-the-art data security.

To begin the process, identify a champion at your company who is familiar with both your operation and the additive world. Lean on their strength and commitment to improve your company and better position it to remain innovative and competitive in today’s changing marketplace.

By Steve Vosmik Head of the Additive Manufacturing Center of Competence, Siemens Industry, Inc.

By Steve Vosmik Head of the Additive Manufacturing Center of Competence, Siemens Industry, Inc.

Contact the author:

Steve Vosmik – Head of the Additive Manufacturing Center of Competence

Siemens Industry, Inc.

steve.vosmik@siemens.com