Need to square up big or small blocks of material quickly? That’s exactly what Blanchards were made to do. They are valuable machines for any shop. The vertical spindle rotary surface grinders, manufactured by Bourn & Koch in Rockford, Illinois, have been around, virtually unchanged, over a hundred years.

Need to square up big or small blocks of material quickly? That’s exactly what Blanchards were made to do. They are valuable machines for any shop. The vertical spindle rotary surface grinders, manufactured by Bourn & Koch in Rockford, Illinois, have been around, virtually unchanged, over a hundred years.

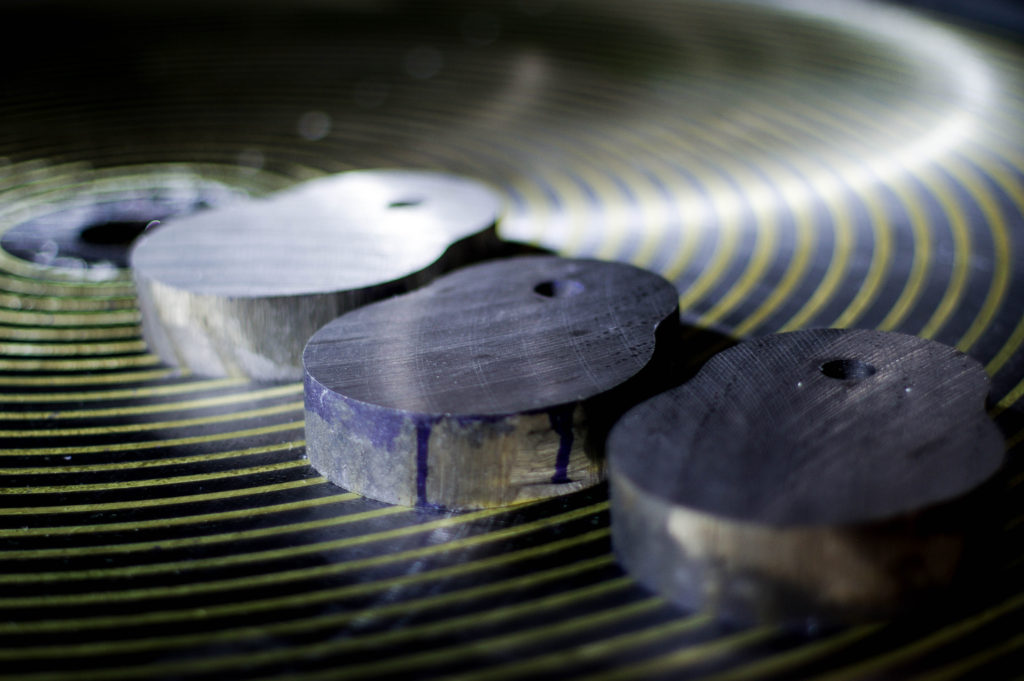

Designed to quickly remove stock in a horizontal plane from ferrous or non-ferrous materials, Blanchard grinders leave behind a flat surface with a signature cross-hatched, spiral grind pattern. The blocks of material being ground on a Blanchard can be as large as twelve feet across (or more); or they can be much smaller parts ganged-up to fill the table. The horsepower and solid design of a Blanchard grinder makes quick work of heavy material removal.

Modernized and Optimized – The Blanchard Metamorphosis

Since 1909, over 16,750 Blanchards have been built (all but 600 of them in the US). The fact that so many vintage Blanchards exist in their original state and are still grinding just as precisely today as they did 100 years ago, is a testament to their quality and intelligent  design. Obviously, technology has come a long way.

design. Obviously, technology has come a long way.

Guided by the sound design concepts and structures from the past, Bourn & Koch is modernizing these classic machine tools for anyone looking to bring their old or new Blanchard machine into the 21st century without sacrificing any of the original OEM specifications or quality of the grind.

With 2500 years of combined engineering know-how in the Bourn & Koch archives (their extensive records and original machine drawings from nearly 30 American-made classic machine tool brands date back to 1896), the team has an extremely valuable resource from which to draw when approaching a customization or re-engineering challenge. The fact that Bourn & Koch IS the OEM for Blanchard, means “the numbers match” – a Blanchard won’t leave Bourn & Koch unless the tolerances match or are superior to the OEM standard, which is parallelism to ± 0.0002” or better across the diameter of the part.

“We’re proud to keep the machines that built American Industry running to this day,” says Greg Champion, Bourn & Koch vice president of sales and marketing. “Our 147,000 square feet of Made-in-the-USA manufacturing capacity is located in Rockford, Illinois; and that’s where new Blanchards are manufactured to the highest standards of quality. Last week we shipped a 60” diameter chuck machine to Kuwait. And recently we produced a 120” diameter machine for Canada. So those sizes are still available new.”

Keeping everything that makes a Blanchard a Blanchard, Bourn & Koch’s team of engineers took on the task of reexamining the loads and damping requirements to reduce the use of outdated, labor-intensive techniques and components (such as hand-scraping and castings) which can be costly for customers to repair when damaged. They replaced that old-school tech with time-proven, up-to-date structures and mechanisms for rigidity, and optimal axial movement, control, and feedback.

Keeping everything that makes a Blanchard a Blanchard, Bourn & Koch’s team of engineers took on the task of reexamining the loads and damping requirements to reduce the use of outdated, labor-intensive techniques and components (such as hand-scraping and castings) which can be costly for customers to repair when damaged. They replaced that old-school tech with time-proven, up-to-date structures and mechanisms for rigidity, and optimal axial movement, control, and feedback.

Because technologies exist today which weren’t available last century, Bourn & Koch engineers can enhance the Blanchard design to propel the machines into greater speed, reliability, versatility, precision, rigidity, and reduced cost to operate and maintain.

Leveraging Advances

Beginning with the machine base, which has historically been cast iron; the Bourn & Koch engineers have designed a highly rigid new base built from a unique combination of stress-relieved weldments for strength and strategic application of polymer concrete for dampening and thermal stability. The new base has the same table loads and rigidity but improved strength, vibration dampening, and thermal stability over the old castings.

The Blanchard’s vertical and horizontal axes of motion on the spindle column (the “downfeed”, which moves the grinding wheel up and down), and the table slides (the “infeed”, which move the table into position under the grinding wheel), have traditionally been hand-scraped hydrostatic boxed ways. Due to the extreme precision achieved by the craftsmen’s meticulous, labor-intensive scraping of the contact pattern to create optimal lubrication and the careful application of turcite for damping, Blanchards ran smoothly year after year, bearing heavy loads.

However, accidents happen, and when a hand-scraped way gets gouged by material handling equipment or operator error (or it simply wears down after 50 years of use), it affects machine performance and is costly to repair. That’s one reason why Blanchard engineers are now incorporating servo motion controlled linear rails in the machine design.

Linear rails have advanced by leaps and bounds in the last 10 years. They are no longer limited to use with only lighter-duty machine tools. Bourn & Koch engineers have carefully paired new high quality, extremely robust linear rails and servo-controlled motors with the new, special polymer concrete Blanchard machine bases to achieve the perfect vibration damping capabilities across the Blanchard line. The combination allows the machines to consistently meet or exceed Blanchard’s OEM tolerances.

The new heavy-duty linear rails have the added benefit of more precise movements and the capability for higher velocity and acceleration. They also are less expensive to manufacture and are easily replaceable. Plus, the servo makes it possible to control the dynamics on the linear direction of the axes without stick-slip and without requiring as much power. Adjustable speeds let the user find sweet spots for new materials and set those up to switch on the fly.

Evolution of User Control Interface

“We joke that the conversational programming needed for a Blanchard is two words – up or down,” says Mischler. “So, you don’t want to make things complicated. You have to have that simple interface; but it can evolve into what the next generation of machinists is going to require.”  Addressing the next generation of users is key to the control redesign across Bourn & Koch’s product line. The new human-machine interface on the Blanchard delivers scalability, maximum productivity and versatility and includes a small handheld controller that lets operators walk around the machine.

Addressing the next generation of users is key to the control redesign across Bourn & Koch’s product line. The new human-machine interface on the Blanchard delivers scalability, maximum productivity and versatility and includes a small handheld controller that lets operators walk around the machine.

“With the new controller, you can just snap it off and you have the freedom to go over and look at the part while you’re operating the machine.” explains Mischler, “You also open up the possibility to auto-dress the wheel, perform in-process gauging, or trigger automated spark out and retraction. But, some customers don’t want anything fancy. We can also set it up to emulate the traditional control. Either way, operators get the simplicity they’ve always enjoyed; but now they have access to features that expand the machine versatility when needed in the future.”

Custom Engineering

In addition to the design improvements, customers can also select from a variety of standard Blanchard options; or have a custom machine or automation solution built by Bourn & Koch. Options include: increased magnetic chuck sizes, larger swings inside the waterguards, and increased grinding spindle horsepower for larger models.

“We are Blanchard,” states Champion. “If a customer wants a Blanchard built exactly to the original OEM specs, with castings, boxed hydrostatic ways, and push button manual controls, for authenticity or perception or nostalgia or whatever reason, Bourn & Koch can make that happen too.” “No matter what the Bourn & Koch customer wants or needs, they will get a US-built

“No matter what the Bourn & Koch customer wants or needs, they will get a US-built

heavy-duty grinder that has passed the Blanchard Run-off Protocol as certified by the block test documentation,” explains Champion. “That’s something we do standard for Blanchard; whether you ask for it or not.” Customers are invited and encouraged to physically witness the block test run-off in person themselves. Those who are unable to attend, can instead request video documentation. “Before it leaves our doors, it will be ±0.0002”,” Champion continues. “That’s not a maybe. It will be ±0.0002”. Otherwise it doesn’t leave.” Bourn & Koch also offers sound tests for customers with limits on machine noise levels.

Bourn & Koch engineers have extensive workholding engineering expertise and can develop custom pocketed fixture plates, vacuum tables, or other types of workholding devices needed for specific customer applications. Likewise, Bourn & Koch also specializes in developing and optimizing grinding processes for customers – matching a special Blanchard machine to particular customer materials and grinding specifications to achieve the desired finishes and cycle times.

Standard Blanchard model numbers indicate the size of the grinding wheel and table diameter; a 76HD-120 model has a 76” grinding wheel and a 120” table (with a swing of 144” inside the waterguards – or up to 164” with optional extended swing). Depending on the model chosen, Blanchard machines can accept parts up to 33” thick standard, or 60” with optional vertical range. Maximum table loads on the chuck are 30,000 lbs.

Blanchard rotary surface grinders come with a new 1-year warranty on the entire machine, including parts and labor. Bourn & Koch accepts old Blanchard and other machines on trade.