American manufacturing is experiencing unprecedented levels of investment with a significant focus on improving industrial supply chains. Manufacturers of all types and varieties are spending money to improve visibility and reliability, but the reliance on maintaining a lean foundation remains intact. With so many options in 2023, the goal becomes finding just the right technology mix to achieve an efficient and profitable balance.

For manufacturers considering a digital vendor managed inventory (VMI) solution, picture a world where real-time consumption data flows through a customizable, secure, cloud-based, easy-to-install and deploy platform that makes valuable information visible to both the suppliers and the consumers. As a bonus, this solution ensures a lean inventory pipeline with no stockouts.

The technology is robust, but simple to use. Consumption data is used to automatically generate the required supply chain documents, automating sales order entry for the suppliers and eliminating purchase order entry and receipt entry for the consumer.

This type of inventory automation is a big win for the entire supply chain. If you want to know what is on your shelf, a digital VMI platform provides complete visibility and massive amounts of data to track.

But there are even more advantages—such as collaboration among suppliers through data-driven CloudSourcingTM, which allows independent suppliers to work together with a consumer on a single RFID-powered supply chain platform to manage complex industrial supply chains.

The traditional approach to industrial distribution growth has been a business model in which various product verticals are added to an existing distribution network to grow revenue and add economies of scale. It’s worked that way for many large distributors for decades.

However, as markets have grown and matured, that traditional way has become less of an option for independent distributors as a long-term growth strategy.

The biggest pushback to the idea of collaborative CloudSourcing™ has been reassuring companies that their customer bases will not be poached by potential competitors. However, the upside outweighs the downside exponentially.

It’s natural to have the fear of sharing information about your customers. However, when industrial manufacturers begin adding suppliers to a digital VMI platform, collectively the suppliers become very efficient and intrinsically valuable to the manufacturing consumer.

By acting as one, the suppliers now become much more valuable to the consumer and less likely to lose market share to their individual competitors. The business is predictable. Long term stability means momentum can be built. Established business becomes concrete and stable.

Another advantage is that the collaboration business model offers a built-in referral system among suppliers. New opportunities are effectively delivered. Suppliers can also approach other suppliers that they have relationships with and invite them to join their digital VMI network to bring the best and brightest of industrial suppliers to a single consumer.

How Collaboration Improves Uptime

How Collaboration Improves Uptime

In industrial manufacturing plants, MRO parts cribs are organized to keep all of the machinery in the factory operational. It is critical to maintain inventory for some long-term, wearable product categories like abrasives, bearings, pillow blocks, belts and pulleys, and rollers.

Some digital VMI platforms offer the ability to host several MRO crib suppliers. Rather than having one crib supplier and hoping that the generalist can fill all those product categories, now it’s possible to use three or four specialists in your area and fill those product categories with several companies that look like one, feel like one, and all share the same magical user interface to access parts from the crib.

This type of collaboration among suppliers in a single digital VMI leads to better uptime because better MRO parts that are sourced from better companies are now available at better prices and with better engineering support. The suppliers pay closer attention to their particular supply chains because they are committed to providing particular parts—such as bearings, belts and pulleys, or robotic machinery parts.

Downtime is not just about manufacturing machines breaking down. Waiting on one particular component that is out of stock can result in hours, days, even weeks of downtime that can cost a factory hundreds of thousands of dollars every day.

Eskridge Senior Supply Coordinator Richard Griffin said he would spend hours, sometimes days, each week ordering O-rings, snap rings, seals, and other parts to keep production moving for the Kansas-based power transmissions solutions provider. “Now, I spend that time sending out quotes for cost savings, looking for new vendors, sending out quotes for new products—all important tasks that I simply did not have the time for previously.”

RFID-powered smart labels provide a magical user interface that allows Eskridge to know exactly what parts are on the shelf. “The last thing I want to do is hold up production of a $100,000 gearbox because I’m waiting for a .017 cent part,” Griffin said.

A robust digital VMI platform provides collaborating suppliers with real-time inventory and accurate, granular data that tells them exactly what is physically on the shelf at any time. Providing that on-hand, real-time information to suppliers is the best chance manufacturers have of not running out of critical parts and avoiding expensive downtime.

The real-time visibility is an advantage, along with the ability to work with independents who are focused on product verticals as opposed to generalists. The data visibility a digital VMI platform provides to the machinery users allows them to see exactly what is sitting on their own shelf.

Collaboration Changes the Game for Supply Chain Management

If an industrial manufacturer is working with four different parts suppliers to build a particular product, a digital VMI allows all those suppliers to be on the same platform without disclosing proprietary information. Within the digital platform, the suppliers can only see their own data and not the data of the other collaborating suppliers.

However, the manufacturer can quickly see which components are available from which suppliers because the collective data is visible to them. The consumer collaborates with their partners, but the partners don’t have to collaborate with each other.

The platform provides them with the flexibility to filter the data to look at only one product or one category supplier. They could also filter the data to look at items that are close to stocking out, or they could filter the data to look at items that cost more than $100, for instance. All these filters are designed to provide visibility and useful data across all the product category suppliers. For proprietary reasons, that visibility is only given to the consumer.

There has never been visibility or accountability with a traditional VMI—the supplier hordes the data and doesn’t provide the actual data to the consumer.

Before digital VMI technology existed, suppliers were forced to have multiple branch locations to physically deliver components to manufactures, as needed. Now, even small-town, remotely-located manufacturers have the ability to get parts quickly, efficiently, and without the risk of stockouts that can halt production indefinitely.

Another understated benefit of automation happens when onboarding a particular product vertical onto the digital VMI platform, for example O-rings—an inexpensive but frequently-used component. The MRO crib is populated with several bins of different sizes of O-rings that are always kept in stock. Historically, manufacturers run out of them frequently. With automation, industrial manufacturers can simply set the system to reorder the inventory automatically.

When you “set it and forget it” on several product verticals, the manufacturer can remove all kinds of daily clutter like multiple purchase orders and the physical counting of shelf inventory.

Machinery owners and facility managers can eliminate all the busy work and paperwork and focus on manufacturing their products with minimal downtime.

For example, Detroit-based Bearing Service supplies bearings and power transmission products to major manufacturers of steel and asphalt. Their MRO crib contains bearings and drive belts.

A digital VMI provides MRO suppliers eyes on their inventory 24/7 with accurate, granular consumption data in real time. It allows companies to work with several independent suppliers, which provides a better supply base than working with a single distributor of multiple products. A specific supplier list can be easily curated. Pushing the data to the consumer through the dashboard provides the machine plant manager their own dashboard to see exactly what’s on the shelf and what is running low.

In a traditional VMI scenario, when parts are not available for a manufacturing line, the operator must stop the machine, run to the warehouse, find the components, then return to the operating line. If the bin of O-rings, for example, is empty, production is halted until parts can be obtained. It’s a time-consuming, manual process.

They must call the O-ring supplier, order the parts, write a purchase order, do the paperwork, and then wait. Perhaps the supplier is located nearby and can drive the parts to the factory. But if the parts must be shipped, then there is a much longer delay. Meanwhile, the line is down. Production is stopped.

With a sophisticated digital VMI platform, that scenario becomes obsolete. The manufacturer never runs out of the needed parts because once the inventory reaches a pre-determined level, parts are automatically reordered and replaced on the shelf. Purchase orders are generated automatically. Because the data is accurate and granular, the inventory can remain at the leanest possible level without ever stocking out.

Automation and RFID Technology Enhances Inventory Management

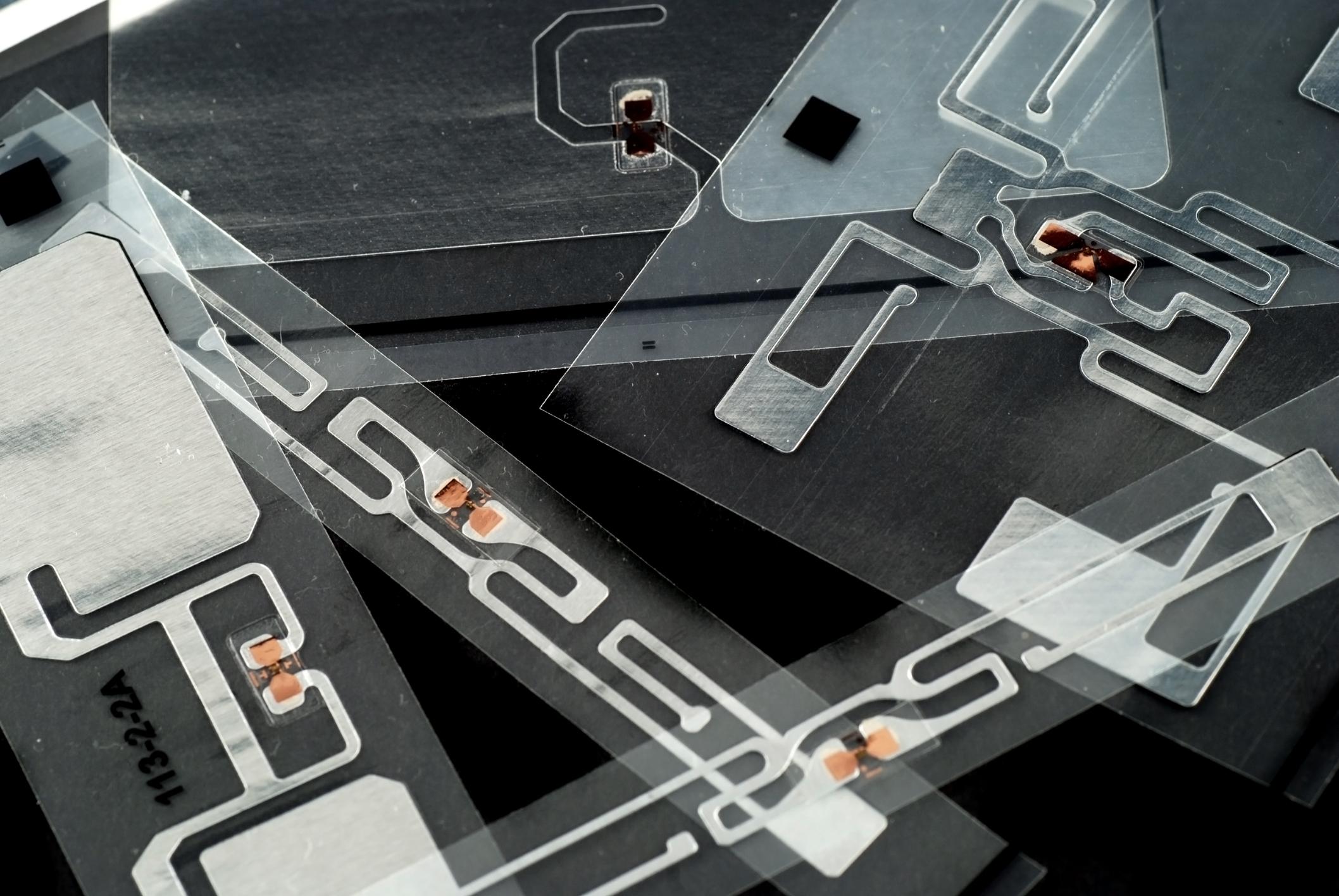

A magical user interface, like RFID smart labels, eliminates the need for screens, keyboards, and handheld or peripheral devices—all of which most manufacturing floor operators find inconvenient and obtrusive.

Traditional VMI systems use barcodes to track products, but that system is outdated. It’s not practical for a consumer to scan hundreds of barcodes per day, and the data collected is limited.

With RFID technology, the user can collect a bag of 500 pieces along with 100 other various pieces in a tub. When placed on the scanning table, one RFID swipe calculates the entire inventory of all the pieces in the tub in seconds and with extremely accurate data.

Larry Hale, Eskridge Shipping/Receiving/Inventory Lead Man, said the accurate data is a game changer.

“We know if we take a bag of 10 out, when we scan the bag the parts are taken out of our system and we know we can make 10 units with that bag,” Hale explained. “If not, we need to figure out why we didn’t. We are much closer on our inventory this way. We are not losing as much, which saves us money. It’s pretty simple. You just set it on the table and when the light changes colors, you are good to go. It eliminates us having to call the vendor to tell them we are out of something. It’s automatic. When we get down to a certain number, they send us more parts.”

It’s important for manufacturers to consider ways to incrementally adopt technology. By creating more automated and robust supply chains that work more closely with the suppliers that are independent and specialized, a focus is placed on the product verticals that are needed to keep a manufacturing facility running.

By Andrew Johnson, CEO, ShelfAware

About the Author

About the Author

Andrew Johnson is an entrepreneur, inventor, and business owner. Formerly the sales manager at the family distribution company, he is now the CEO of ShelfAware, which is redefining industrial supply chains by leveraging RFID technology, the internet, and the power of data. He can be reached at andrew@shelfawarevmi.com or (913) 270-8400.