We were able to carve out some time from ANCA’s group CEO Martin Ripple recently, and get a great perspective on the tool making machines from ANCA as well as some strategic insight on future direction and capabilities. Martin spoke about AIMS, which is the ANCA Integrated Manufacturing System, as well as some of the characteristics of ANCA products.

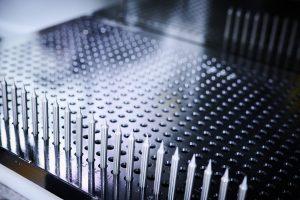

ANCA builds their machines from top to bottom – which is critical when producing machines that operate with tool making motion control tolerances in the nanometer range, and a couple of microns range on many others in terms of precision finish.

From Germany, with some time working with German automakers, Martin Ripple brings a breadth of leadership experience to the ANCA Group CEO role. His unique skills were developed in senior roles across the aerospace, defense and information and communications technology sectors. He has worked for large multinationals as well as family-owned enterprises, and has strong stakeholder management and people leadership skills. With an engineering background, Martin has led successful growth strategies in the engineering and technology sectors, including the commercialisation of products in global markets.

The topics which I wanted to cover included everything from Business 4.0 to future strategies. After an overview of ANCA’s business units (for more information please go to www.anca.com), we dove right into some of the next generation capabilities of ANCA’s products – so this is picking up after a few questions and answers have already been exchanged.

Meeting Precision Manufacturing Tolerances

Meeting Precision Manufacturing Tolerances

Martin Ripple: Our motion control is in the nanometer range. This gives you precision in everything you do including temperature control. For instance, 0.2 of a degree centigrade puts you out of tolerance for some processes. You want to keep everything stable and we’re using the algorithm to control the motor temperature, to make sure that nothing in the machine is getting pushed or pulled, especially through the spindle in a way that we don’t want to. We believe that vertical integration has allowed us to reach new levels of precision. I mean you can’t compete in a modern world on the run of the mill type of stuff, right? You’ve got to lead with innovation, you’ll lead from the front and that’s where ANCA is particularly strong.

Trey Bell: That’s where the German automakers have also set the standard with some of their technology innovations and I’m sure that experience, and, having been around that, is useful for you in what you do. How does all this relate to productivity in manufacturing?

Martin Ripple: A focus on productivity is a recurring subject of my career and I’ve thought about it extensively. It’s a difficult subject because it has multiple dimensions. Ultimately, for me, a productivity gain is the only way a company can stay competitive in the market. Now, you want to produce more with less be that with less energy that you put into the process, or less time. Less manpower. Less investment.

Trey Bell: Right.

Martin Ripple: Of course all these inputs – energy, time, space required, human resources, investment, they’re all connected. But ultimately, you want to drive productivity by improving or reducing those measurements.

There are a multitude of reasons that companies will be looking to improve their production efficiencies. For example, a well known trend is the skilled labor shortage, and to beat it you need to work smarter, not harder to make a meaningful difference.And so I am incredibly interested in looking at if you keep everything static, you keep your energy cost static, you keep your labor cost static, the cost of the machines static, how can you get more out of it? We came to the conclusion a long time ago that it’s automation and robotics. So ANCA has made a massive investment into automation and robotics because we believe that it will make a difference for our customers.

AIMS and Automation Meet Changing Labor Challenges

AIMS and Automation Meet Changing Labor Challenges

Trey Bell: Let’s talk about advanced manufacturing and Industry 4.0 and give me your thoughts on what that means to ANCA.

Martin Ripple: We find that different parts of the world have different requirements when it comes to skilled labor. In some countries, like Korea they have laws that dictate how many hours a person can work or in Switzerland the cost of labor has made manufacturing at times cost prohibitive, or simply that people no longer want to work overnight or on weekends.

These challenges mean automation is key to productivity. And even before our ANCA Integrated Manufacturing Solution (AIMS), we used automation in our machines and these efficiencies saw some businesses onshoring their production thanks to this technology.

And the young folks coming in, they want to do programming stuff, they want to work with robots. So we embarked about five years ago on this journey and asked ourselves 1) What can we do to increase productivity on the shop floor? And 2) How can we connect our machines? That’s when we came up with ANCA AIMS. And that is the value proposition of AIMS: Reduce labor requirements in terms of hours and skills, improve process stability and of course increase asset utilization.

Trey Bell: So that’s your kind of combination of AI and Robotics, resulting in this whole environment that addresses the question of how do I manage limited access to highly skilled people and avoid having them working on low-value adding processes like manual handling of the jobs to make them more productive? In an environment that is more automated and costs less to operate.

Martin Ripple: We are also supporting customers through technology and through interconnectivity between different machines. With AIMS we see the entire factory as a single machine. So it connects all the production elements you need on a shop floor and connects it at the AIMS server level into one system. Employees can then focus on more value adding activities and that drives productivity. I’ve got a couple of numbers here for you if you’re interested. A Polish customer who has recently implemented AIMS has a target improvement to reduce labor costs by about 60%. We’re not talking 2% or 3%, instead these are really big numbers and significant savings.

Trey Bell: That’s huge.

Martin Ripple: Originally people looked at us and said, what are you talking about? But we’re looking in this specific case at a 60% labor cost reduction.

Trey Bell: Wow.

Martin Ripple: It’s nothing against humans, it’s just that our customer says they can’t find them. How am I supposed to run a facility if I can’t find the people I need to do the work? Another benefit of automation, if I can be technical for a second Trey, is that the repeatability of the tools that are produced by the machines is also higher. If you drive in a Tesla and always the same stretch of road, Tesla will keep the car in the same spot which eventually will lead to road damage.

Martin Ripple: It’s nothing against humans, it’s just that our customer says they can’t find them. How am I supposed to run a facility if I can’t find the people I need to do the work? Another benefit of automation, if I can be technical for a second Trey, is that the repeatability of the tools that are produced by the machines is also higher. If you drive in a Tesla and always the same stretch of road, Tesla will keep the car in the same spot which eventually will lead to road damage.

The same thing happens in tool making. Operators have their own work techniques to get tools done. But with an automated process you get the absolute closest stability. You see trends because you measure the tools after they’re made and you can correct trends before they push a tool out of tolerance. There’s multiple advantages of using AIMS and the changes we’ve seen are awe-inspiring. We think with robotics you can achieve about 50% productivity gain per year. Building an integrated system is an iterative process. We built AIMS as a modular system, you can start small and then you can get bigger and add more elements as needed. I sometimes liken it to one of the machines talking to the next machine, but then you add another machine to it and it’s a gradual path. Of course, if you build a new facility, we can help you to build the facility from the beginning on the AIMS standard.

Typically people have invested in an established collection of machines. Our system is a toolbox that you can add to with AIMS Ready machines…

Trey Bell: Basically, they can talk to each other and they can share analytics data, a communication channel, and I guess there’s some terms possibly like OPC-UA or other protocols for folks like me down at the lower level, the gearhead level

Martin Ripple: Yes.

Trey Bell: What I think I’m hearing you say is that you can drop the machines in and you can treat them almost like a black box where you have something at the beginning. Then you’ve got value added in that black box in an automated fashion and you get a finished item on the back side, or what you intended to have as the output.

Martin Ripple: That’s right. We believe that 50% per annum productivity gains are achievable and we think ultimately productivity gains of about 300% are possible. Now imagine what that does to your cost of operation if you produce four times more at the end of this process by adding more and more AIMS components to your factory floor. My point has been to customers that this is a technology that is still in itself evolving; by joining the party early you can influence the direction. In your production, in your manufacturing processes, you might be specifically keen to have a certain functionality or certain capability built in. We work with our customers to make sure every single AIMS system is built around a specific customer need. The technology is the same but tailored to individual needs as everybody approaches tool making slightly differently, and we’re here to help.

Trey Bell: Let’s talk about those customers that may be a little different right? They have ANCA machines and they have other machines as well. And tell me a little bit about interoperability. How do you work in that environment? What kind of focus do you have making sure that these machines can all speak together and generate improvements. Have you got any thoughts on that and how that’s impacting your business?

Martin Ripple: Of course. The first thing we did is we created an interoperability with ZOLLER machines, and we are working on additional interoperability to other measurement machines. [ed note: one of the product offerings from ZOLLER is metrology machines]. We’re working on those because really they are the first interface you want to have in place.

Trey Bell: You have to be able to measure the tolerances that you’re talking about. Probably with a laser.

Martin Ripple: That’s right. And we are in the process of leading the industry to adopt a common standard between machines because we want AIMS to be agnostic to the machines. So from the beginning we said we do not want this to be a closed ecosystem where we say “You have to go with ANCA.” Ultimately, we recognize that competition is always good for business. We still believe we’ve got the best machine, but we know that customers out there have different machines and so AIMS was designed as an agnostic system that ultimately will be able to talk to all these machines.

Trey Bell: That’s pretty smart. You’re actually coming out at a platform level to be the backdrop for everything, so that everything can plug and play.

Martin Ripple: It doesn’t make sense to force somebody down the road by saying you must buy an ANCA. I don’t think it would work and I don’t think customers would appreciate it. Also as you and I know there’s hardly ever a revolution but rather It’s always an evolution that gets you to the objective.

Martin Ripple: It doesn’t make sense to force somebody down the road by saying you must buy an ANCA. I don’t think it would work and I don’t think customers would appreciate it. Also as you and I know there’s hardly ever a revolution but rather It’s always an evolution that gets you to the objective.

Trey Bell: Yes, that means you have got to put some heavy focus on software, right?

Martin Ripple: That’s absolutely right. That’s where I guess the German guy running the show is coming into play because other than aerospace I have done lots of IT in my past.

To be at that level where you aggregate and consolidate, you’ve got to be able to influence the interfaces and massage the interfaces so that the industry is coming together and working together. We are intending to play that role, actively and through transparent means by coordinating standards committees. Getting industry together around EMO to talk about standards is a crucial part of that.

Martin Ripple: I do remember my early days when I started at Mercedes and the first thing they said to me is that we are going over to meet people from BMW and naive as I was I said “Well, I thought you were competing?” They said yes, we were competing on a car level, but without similar standards, nothing is effective or will work together. In Germany, when you have the radio tuned in, traffic information actually comes on top of the radio waves. It doesn’t matter which car, it doesn’t matter which radio station, they add some bits and bytes to the radio waves that you can’t hear. But the radio understands, and then translates them into navigation signals such as someone is driving the wrong direction on this highway or there is a traffic jam behind the turn, which on an autobahn driving 200 mph, it’s kind of healthy to know that the traffic is coming to a grinding halt in front of you. And so they work together on those standards. And they said, of course, we’re going to compete on a car level, but that doesn’t mean we can’t work on an industry standard level together to make a better product for our customers ultimately. That’s a very similar approach we’re taking here.

Trey Bell: You raise the boat for everybody, right? You raise it up and everybody wins. And everybody makes more money because you’re operating in a standard environment.

Martin Ripple: Exactly, right.

Trey Bell: Yes, so this is really what I would call your new business model, in terms of how your company is evolving to address interoperability, and also maybe get into new places, which could be some value added software capabilities or other items like that.

Martin Ripple: That is right. We believe the ANCA in 20 years time is going to look different from ANCA today. Let me give one last example relevant to our approach from the automotive industry. I believe this industry has underestimated for a very long time how important the interface and car software is to people, especially the German automakers who were I think very much focused on their combustion engine and engine power. My view was always different. For instance, when you next rent a car – see whether you can remember three days later what kind of car it was. I can’t although I’m a car guy. But I can remember whether it spoke to my phone or not. I can remember whether it was an easy kind of navigation system. But do I remember what size of engine I had? Or what brand the car was? No I don’t. They all look the same, they all feel the same, they all drive the same. So I think we should not miss that momentum and experience on the software side for ANCA, I think it is incredibly important.

Trey Bell: I could see an example in your machines regarding specific settings for the operator. And then those being saved in his device, so that when he shows up to work the next day, he doesn’t have to change anything because the whole profile is saved on his phone.

Martin Ripple: As an example, absolutely. It will be exactly as you say. Most modern customers, or modern shops, that you walk into of course anybody working there has an iPhone. That’s the level of human machine interface expected today by the operators. So we’ve got to be there. And AIMS does lift that up to the next level where the entire factory is one machine. You’ve got full data transparency, you’ve got predictive maintenance, you put data into the cloud. You could combine numerous sites that you have into one overview. We’ve got the ANCA REDAX software solution that allows you to really measure the productivity of your factory and intervene early, whether it’s around maintenance or tool life or certain parts that have certain life limiters, change of consumables, and other operating parameters. So it really allows you to go to the next level. We have achieved for one customer 66 hours of operation which is our objective for AIMS with all customers. 66 hours, which is from Friday afternoon to Monday morning. You should see the smile on the face of the factory owner when they come in Monday morning and the machines produced a hundred thousand dollars worth of tools over the weekend without a single human being in the loop.

Trey Bell: Wow.

Martin Ripple: Of course they’ve got SMS alerts for the maintenance truth and analytics information. But how beautiful it is that you come back into your factory and it has actually worked throughout the weekend while you went fishing or flying or surfing.

Global Shifts

Trey Bell: That is very powerful. Let’s shift gears a little and talk about one of the biggest items we are seeing in manufacturing right now – the move to electronic vehicles on a global basis. How does ANCA play in that manufacturing transition? Does it have any bearing on your strategy?

Martin Ripple: Yes. The first thing I’d say is our strategy has been and will be to produce the highest quality tools and that makes the link to EVs fairly obvious. EVs typically have less parts compared to a combustion engine. We’re talking about 50% fewer parts than in an internal combustion engine car. But the parts themselves have to be of higher quality. So for instance the drivetrain of an EV has RPMs of 20k-25k. If you have parts that are not down to the micron, they become pretty noisy. ANCA’s GCX Linear sets a benchmark for skiving cutter grinding, which is revolutionizing the gear manufacturing process.

That need for the highest quality tools is why we have introduced The Ultra series. We’re introducing it at EMO in September (ed note: see previous insert on EMO), and it is the first time we are announcing this to the markets, the FX7 Ultra produces the highest quality tool. Of course, that tool with that quality leads them to a higher surface finish. With those higher surface finishes, we’re talking gearboxes or gears that touch each other, they make a lot less noise because of that smooth surface finish. The link to what we do is we believe you have got to have a vertical integration of your manufacturing process to produce The Ultra, which has nanometer resolution on the motion control. It has more temperature control, which is again patented in the US. It has servo control algorithms that we call Smooth-As-Silk around the curves, to make sure that those pieces into gears are incredibly smooth for those high RPMs.

Trey Bell: Higher efficiency. All right.

Martin Ripple: And of course because those machines and those cycle times needed to create those gears are fairly long, you occupy the machine for a fairly long bit of time. What you don’t want is an operator to put something in and wait 10, 15 minutes and stand around doing nothing. And that’s why again we believe that we are coming back to automation. Wouldn’t it be nice if machines were loaded automatically and then the robot picks it up and measures it? And guess what? We’re already selling about 90% of our machines with loader robots. So that’s the first step to load them up with robots.

AIMS is in the next step. Not only load them up, but also pick up the specific part, bring it to a measurement machine and then if required do some rework on the part. You can see the holistic picture, right? You want an Ultra series machine because that gives you the precision and the surface finish that you require for EVs. But as those parts become more important, and the cycle times become on occasion longer, you want that AIMS controls the whole thing and delivers it – increasing productivity ultimately.

A Technology Research Park

A Technology Research Park

Trey Bell: This has been a great discussion on innovation at ANCA. I also saw in your article something about manufacturing precincts. Can you expand on that?

Martin Ripple: We are looking at creating a manufacturing precinct. We are currently in the planning stages for a new manufacturing precinct here in Melbourne, in Australia. This is a complement really with what we’ve built around the world, with what we call a global footprint of manufacturing partners, of manufacturing sites that ANCA owns, and regional offices in Wixom, in Michigan in the States, and near Heidelberg in Germany. We are in 28 countries now with our offices, being close to the customer and really being able to service the customer and help them with application engineering and other critical support. So we are continuing to be very local, but at the same time we will have a manufacturing precinct here. We believe that if companies work together in close proximity, it just gets the creative juices flowing. You are able to achieve so much more by doing it together. And so that’s what we’re currently working on. It’s very very early that I kind of released that information to you but we’re at the early stages of planning.

Automation and connectivity of the machines is really the only way the West can stay ahead in the game and stay competitive on a global scale. We can’t compete on labor costs or availability. We can’t compete on the willingness of some countries to work 24/7. We’ve got to do something and in our world, it’s automation through robots and connectivity through AIMs. That’s how you get the competitive edge.