For a company that provides maximum agility to its customers in need of high-volume 3D printed parts, 3DEO stands as the perfect example of its own business model. Cofounded in 2016 by three partners who met at the University of Southern California, two of whom were completing graduate studies focusing on binder jetting technology, the original intent was to produce a low-cost 3D printer as an additive manufacturing OEM. Early lessons learned include that prototyping was already well-served, as was low-volume printing. The real niche that needed filling was soon revealed to be high-volume parts production, and the epiphany that customers didn’t really want to buy the printers, they just wanted to purchase parts in the quantities and to the specifications they required.

For a company that provides maximum agility to its customers in need of high-volume 3D printed parts, 3DEO stands as the perfect example of its own business model. Cofounded in 2016 by three partners who met at the University of Southern California, two of whom were completing graduate studies focusing on binder jetting technology, the original intent was to produce a low-cost 3D printer as an additive manufacturing OEM. Early lessons learned include that prototyping was already well-served, as was low-volume printing. The real niche that needed filling was soon revealed to be high-volume parts production, and the epiphany that customers didn’t really want to buy the printers, they just wanted to purchase parts in the quantities and to the specifications they required.

“That’s when our eyes were opened,” according to Matt Sand, co-founder and president. “We realized that creating a low-cost structure to compete with CNC manufacturing involved much more than the 3D printer itself, but everything that happens end-to-end from the introduction of metal powder all the way to the finished part. So we completely rewrote our business model from being an OEM to becoming a high-volume producer of 3D parts. We created an industrial platform built around our technology with the goal of being a ‘next-generation factory’.”

The benefits of this approach abound. For one thing, having a natively integrated factory allows 3DEO to produce a hyper-competitive cost structure when bidding projects, Sand explains, with negligible startup costs compared to CNC machining and especially injection molded parts. In the latter instance, molds are incredibly expensive, and often take months to complete, and if there are glitches, the extra time and expense piles up. Plus the manufacturer is basically locked into the parameters of the part dictated by that mold. With 3DEO’s technology, there are no molds, and part designs can be created, corrected, and executed in a matter of days, with a ‘go-to-market’ timeframe that has been slashed from years to weeks.

In addition, the “closed-loop” nature of 3DEO’s platform results in continuous improvement from which all of its customers benefit, not just the one from which the reasons for the adjustment might’ve originated. By gathering data from all points in the process and feeding it back into the appropriate earlier stage, automatically making adjustments that enhance production efficiency, the result is constant systemic streamlining, Sand says. “The only thing you have to watch out for has to do with bottlenecks,” he says, “because as one is eliminated and cleared, that might lead to another down the line, so cause and effect must constantly be monitored.”

In addition, the “closed-loop” nature of 3DEO’s platform results in continuous improvement from which all of its customers benefit, not just the one from which the reasons for the adjustment might’ve originated. By gathering data from all points in the process and feeding it back into the appropriate earlier stage, automatically making adjustments that enhance production efficiency, the result is constant systemic streamlining, Sand says. “The only thing you have to watch out for has to do with bottlenecks,” he says, “because as one is eliminated and cleared, that might lead to another down the line, so cause and effect must constantly be monitored.”

Another key component of 3DEO’s platform involves a healthy relationship between production and R&D, with each aware of the other’s activities and constantly available to provide support and help identify solutions to challenges as they arise. While each area is careful to focus on their primary responsibilities, this close collaboration is central to the company’s whirlwind success. It has recently surpassed the benchmark of 150,000 parts shipped, in fact (see the press release in this issue of IMD).

It’s also a fact that 3DEO’s very structure protects it from technology infringement since its success is based on a manufacturing platform rather than a single process or piece of equipment. It is difficult to duplicate what is basically a business philosophy or mindset, after all, especially when it is groundbreaking.

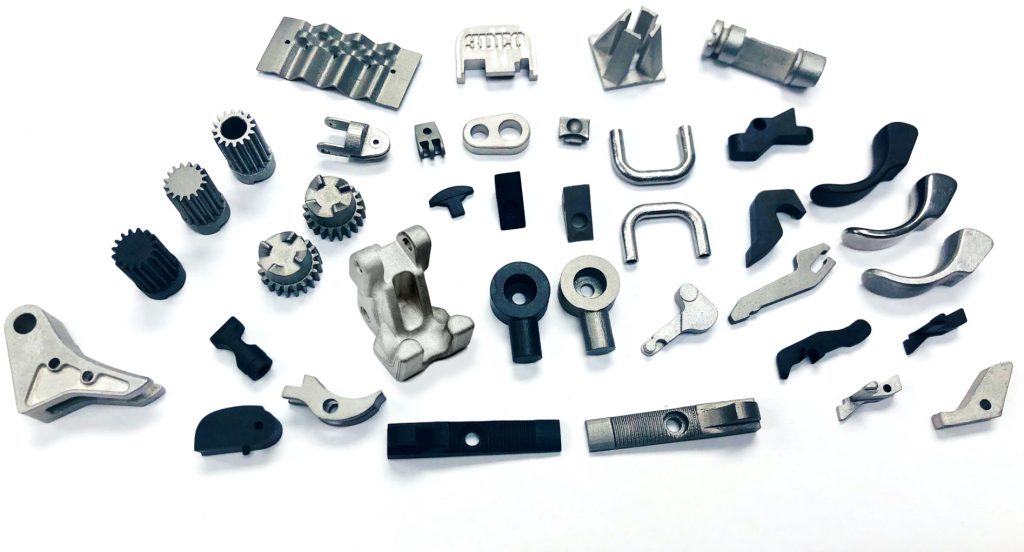

Still, the technology at the center of this system is indeed impressive. Known as “Intelligent Layering Technology,” it involves first applying a thin, uniform layer of metal powder to a substrate, and then binding that layer in its entirety. A CNC end mill is then used to define the part’s geometry layer-by-layer, resulting in incredibly tight tolerances, excellent surface finishes, and part material densities higher than 98 percent.

Still, the technology at the center of this system is indeed impressive. Known as “Intelligent Layering Technology,” it involves first applying a thin, uniform layer of metal powder to a substrate, and then binding that layer in its entirety. A CNC end mill is then used to define the part’s geometry layer-by-layer, resulting in incredibly tight tolerances, excellent surface finishes, and part material densities higher than 98 percent.

Located in Los Angeles near LAX, 3DEO currently confines its activities to the U.S. market, but its position near a global crossroads leaves it well-position for geographic growth. “And another benefit of having created this whole platform ourselves is that we’re intimately familiar with all the moving parts, and they’re all scalable.” Sand says. “So when it’s time to grow, we’re sitting on go!”