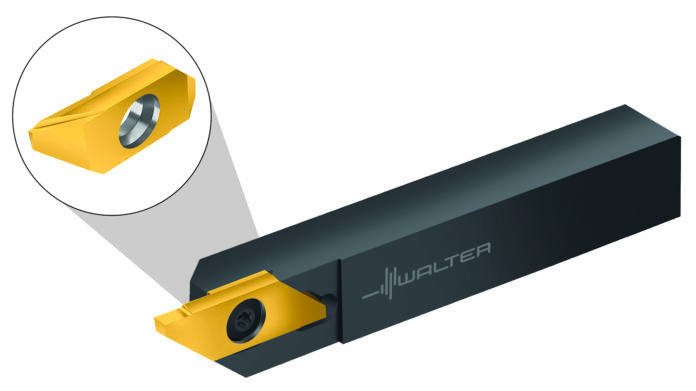

Walter has expanded the product range with the addition of the WT26 indexable inserts and toolholder system, which are primarily designed for small part machining, or Swiss-style turning. The new addition includes tangentially installed partial-profile and full-profile thread-turning inserts with sharp cutting edges to achieve optimal machining results for small diameter workpieces. The tangential inserts feature sharp corner radii and are conventionally known as “zero radius” inserts.

The precision-ground cutting edge and chip breaker groove ensure ultimate precision and tool life when turning. The tools are for turning a workpiece diameter up to 1 mm (0.039 in.) in automatic lathes and multi-spindle machines. The indexable insert screw can be accessed from both sides for simple insert indexing. The toolholder’s shank sizes are 0.500 in., 0.625 in. and 10 × 10 mm, 12 × 12 mm and 16 × 16 mm.

All WT26 insert types fit in the same toolholder. A dovetail profile absorbs lateral, or axial, forces. Suitable applications include parting off and grooving, forward and reverse turning, and thread turning. Grooving along close shoulders is possible thanks to the installation of the inserts at a 1° angle.

The inserts are WSM23X and WN23 carbide grades. The universal physical vapor deposition (PVD) grade is for parting off, grooving and turning with a moderate to low cutting speed (vc) and axial depth of cut (ap). The primary applications are machining steel, stainless steel, materials with difficult cutting properties and non-ferrous metals (ISO P25, M25, S25 and N25 material groups).

The uncoated WN23 is an extremely tough and abrasion-resistant grade for machining non-ferrous metals (ISO N20 material group). Secondary applications include machining steel, super alloys and other materials such as carbon fiber composites and graphite (ISO P, S and non-ISO O material groups).

The inserts feature six geometries. CD8 is for parting off, GD8 is for grooving, VG8 is for reverse back-turning and copy turning, DG8 is for forward turning, RA8 is for full-radius profiling, and UA8 is for grooving and groove-turning.

About Walter

Walter, a global leader in the metalworking industry for over 100 years, offers a wide range of precision tools for milling, turning, drilling and threading applications. The company helps customers in the aviation and aerospace industries, automotive, energy, and general metalworking industry improve process reliability and increase productivity. As an innovative partner capable of creating digital process solutions for optimal efficiency, Walter is pioneering Industry 4.0 throughout the machining industry. With Regional Headquarters in Greer, SC, Walter markets its competence brands Walter, Walter Titex, Walter Prototyp and Walter Multiply through a network of channel partners and field engineers across the USA, Canada, Mexico and Brazil.