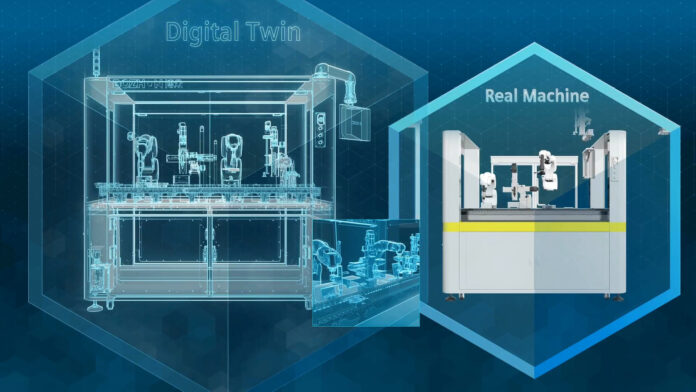

Digital twin in manufacturing also known as Industry 4.0 technologies empowers intelligence to interconnected machines on the shop floor enabling them to orchestrate and execute the whole production in an efficient manner. Even though increasing connectivity, computing power, advanced multi-physics simulation tools, IoT, and new levels of automation permit realizing holistic digital twin in manufacturing, companies still struggle due to the intricate nature of the complex systems, lack of consistent framework, and the precise level of integration between physical and digital domains, data exchange and to some extent the maturity of the technologies.

Digital Twin in Manufacturing Webinar

In this educative webinar experts from Siemens Factory Automation demonstrate their holistic approach to realizing digital twin in manufacturing. From system engineering aimed at component sizing to augmented reality for machine maintenance, we cover all aspects of the digital disruption that is happening today with a practical example from the Technology Application Center (TAC) in Piacenza.

Join their digital twin in manufacturing webinar and we will demonstrate to you:

- A step-by-step procedure to adopt digital transformation in discrete and process industries

- A practical example of the most comprehensive digital twin that allows monitoring machine performance in real-time using augmented reality

- How using simulation, testing and IoT allows merging of the virtual and real-world, hardware and software, design and manufacturing to unlock new insights and unique opportunities

- Performing low- and high-frequency electromagnetics modeling and evaluating EMC/EMI issues in the Industry 4.0 era

- Achieving stricter targets for performance, reliability, safety, and efficiency

Siemens Digital Factory (DF)

Siemens Digital Factory (DF) offers a comprehensive portfolio of seamlessly integrated hardware, software, and technology-based services in order to support manufacturing companies worldwide in enhancing the flexibility and efficiency of their manufacturing processes and reducing the time to market their products.

About Siemens USA

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation, and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 379,000 employees in 190 countries, Siemens reported worldwide revenue of $94.0 billion in fiscal 2018. Siemens in the USA reported revenue of $23.7 billion, including $5.0 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.