OnRobot is a relatively young company. Could you give us an overview?

OnRobot is a relatively young company. Could you give us an overview?

Of course. The company was established in 2015 in Denmark by two engineers who had worked for a robotics manufacturer. They wanted to design grippers and other accessories for collaborative applications that featured easy installation and ease of use; basically technology that you could take out of the box and quickly be ready to go to work. As new investors came onboard, OnRobot was able to acquire companies whose products perfectly complemented our own, which has resulted in tremendous growth. These acquisitions are ongoing. We are now active in nearly every region of the world. North American operations are based in Dallas, Texas.

Talk about the evolution of your product line, and especially this focus on flexibility and simplicity.

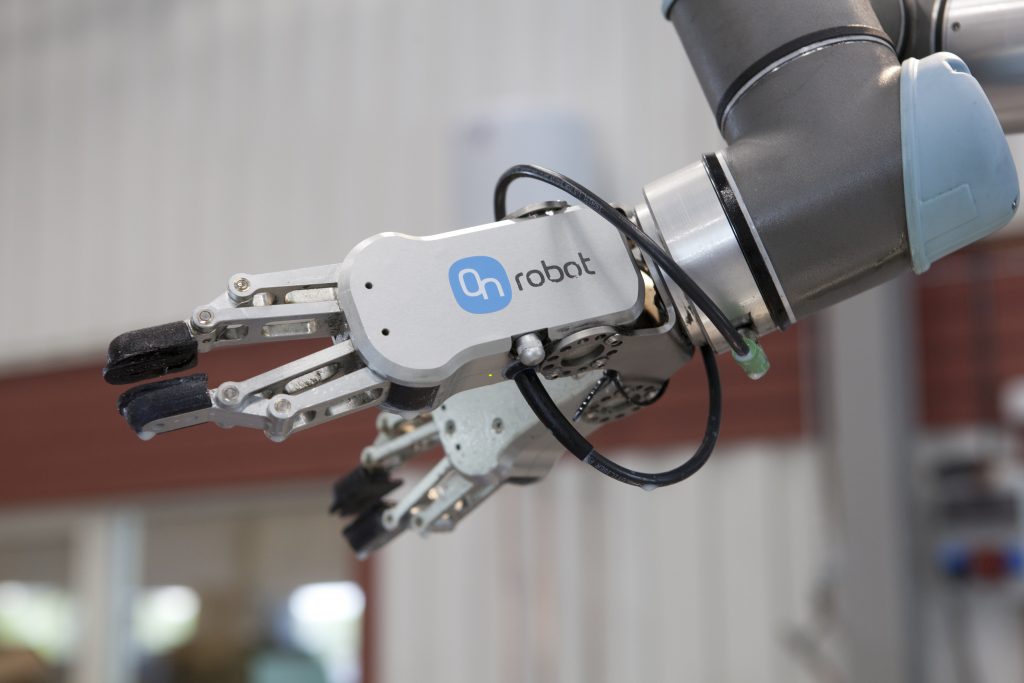

We first launched the RG line of two-finger grippers. These are designed for quick installation and easy programming directly from the robot’s existing controls; there is no extra training required. The beauty of these grippers is the flexibility they provide in shifting production between different parts of varying sizes and geometries. They are powered by electricity, so all that’s required to shift between parts is a quick adjustment to the gripper’s parameters and you’re ready to go, whereas you would have to purchase a specialized unit for each different part if you were using pneumatic grippers. We then introduced the Gecko Gripper, which relies on technology originally developed by NASA’s Jet Propulsion Laboratory (JPL) for space applications. It doesn’t require compressed air, instead utilizing van der Waals forces – the same principle that allows geckos to climb walls – to pick up and transfer flat, smooth and porous materials without damaging the surface finish. Other products include a three-finger gripper, electric-vacuum gripper, vision systems, a soft gripper, and quick changers. And the applications are endless, including pick and place, machine tending, packaging and palletizing, assembly, quality testing and inspection, and surface finishing, among many others. We currently offer about a dozen products, and we plan to launch about 20 more in the coming year. Our goal is to provide all of the products that go on and around robots.

What other benefits do these attributes provide?

It’s been said that within five years, there will be 10 times as many robots in operation. So how do you deploy all the accessories required to make a robot or a cobot operational when you’re dealing with such high numbers? What is the fastest and least-expensive way of tooling up a new robot that’s just been delivered to the shop floor? That’s where the value of easy installation and operation become apparent. In addition, we design all of our products to be mounted to any type of robot, so we’re saving the time some companies would spend having engineers design so many custom models. Our equipment is meant to be plug and play which, if you think about it, is really bridging the gap between the OEM and end user. Our distributors and integrators play an important role in our customer supply chain, but the more the operator can do on their own the quicker they’re able to go into production. Plus, our sales model is set up so that dedicated OnRobot employees strategically manage distributors in their territories, allowing us to closely monitor the markets we serve. This also helps guide our new product development, in that we can respond to a significant need for screwdriving accessories, for instance.