Trey Bell: Bob, Skyhook’s website has a photo of you working at NASA Ames. They tell me you are a very interesting person – a rockstar really.

Bob Walker: Well, I’m not sure about that – but they were looking for a white lab coat type I think, so it makes sense to use that photo I suppose.

Trey Bell: Yeah. Tell me about Bob Walker. You on Saturdays,… when there’s a football game on, do you have a team that you pull for?

Bob Walker: When there’s a football game I’m usually in my private machine shop.

Trey Bell: Great! How did you get involved with NASA?

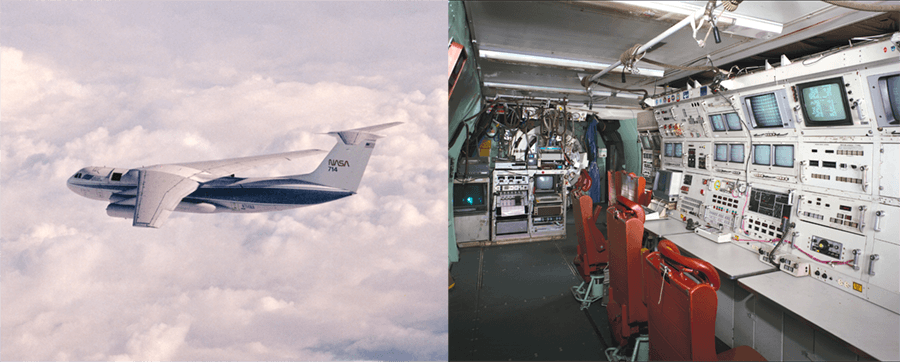

Bob Walker: During the college level, I Heard about the Astronomy program at NASA. And I was at Foothill College Observatory working there. I said, I want to get out there on the airborne research program, on what we call a copper observatory. So when I heard about this, it’s a flying observatory and if you see there’s an opening in the front of the head of the wings,…

Trey Bell: Yep. I see it.

Bob Walker: And that’s the door that moves up and down from 35 degrees elevation to 75 and a telescope looks out through that. And there’s no windows, it’s exposed to the environment outside. So the telescope is at a very cold temperature.

Trey Bell: You got quite a bit of air going over that too, don’t you?

Bob Walker: Yeah, there was a boundary layer fence that they would lift. So the boundary layer will flow over that hole. And this was developed from wind tunnel testing. The telescope itself is sealed in a vault. The telescope is at that high altitude, but we’re in shirt sleeves. The focal point of the telescope will come into the shirt sleeve environment through the windows and that’s where the astronomers instrumentation would mount.

Trey Bell: Which location were you at for NASA?

Bob Walker: Moffett Field. California, Mountain View. I heard about NASA Ames, yes. And when I heard about the observatory program, I decided to go from a ground base to the airport and I actually got picked up right away. When I first started out there, I was a contractor. And I was involved with a Learjet which was the first flying platform for infrared astronomy. It had a little 12-inch diameter telescope in it. It would only handle two pilots and an astronomer. I was there to support that and occasionally, we would have one of the Apollo astronauts come in and help fly the flight. We proved that flying a telescope and looking at stars at night works just great. Then we migrated into the big telescope you saw above, a C-141 and it’s a military aircraft. That Lockheed design was built and the military picked it up. It’s designed so that the back doors would open up and you can load troops, tanks and vehicles. We had the only civilian version. And it was modified for the telescope and that was a 36 inch diameter telescope. I used to handle a 36-inch diameter telescope to flight 41,000 to 45,000 feet.

Bob Walker: Moffett Field. California, Mountain View. I heard about NASA Ames, yes. And when I heard about the observatory program, I decided to go from a ground base to the airport and I actually got picked up right away. When I first started out there, I was a contractor. And I was involved with a Learjet which was the first flying platform for infrared astronomy. It had a little 12-inch diameter telescope in it. It would only handle two pilots and an astronomer. I was there to support that and occasionally, we would have one of the Apollo astronauts come in and help fly the flight. We proved that flying a telescope and looking at stars at night works just great. Then we migrated into the big telescope you saw above, a C-141 and it’s a military aircraft. That Lockheed design was built and the military picked it up. It’s designed so that the back doors would open up and you can load troops, tanks and vehicles. We had the only civilian version. And it was modified for the telescope and that was a 36 inch diameter telescope. I used to handle a 36-inch diameter telescope to flight 41,000 to 45,000 feet.

This and again it’s all in first astronomy. They’re looking at objects in space. It’s basically heat and thermal signature. Radiation that could break up into a spectrum, like you would see through a piece of glass from the sun. The infrared spectrum was the primary for observation. We would observe the sky with infrared, and that’s why the telescope worked best in the outside environment because it had to be super cool.

The program started in 1973 and grew from there. Once we proved it could be done, we would travel to different parts of the world for different parts of the sky. We also went to the Southern Hemisphere. We’d usually go to some part, and look at the skies like New Zealand from New Zealand or Australia.

These observing flights were at least seven and a half hours, And we climbed up to 41,000 feet. And then eventually burn off enough fuel that they can climb up to 45,000 feet. And above 41,000, the three of us that were operating the telescope and running the equipment in the back of the airplane for the astronomers would have to go on oxygen masks. That was kind of an annoying thing because it’s oxygen masks and uncomfortable. But we had to do that because we had a decompression in the airplane. We would be all set. We didn’t have to struggle to put masks on while doing everything else. so we were required to wear a mask, so we would be prepared to do whatever had to be done but that’s where I started. I flew that program for about 15 years.

Trey Bell: After you got out of this program, what did you do next?.

Bob Walker: I went to a group which was also at NASA Ames. And I want to join that group because he needed somebody to build research equipment. And the research equipment we called ice machines. These are vacuum systems that can grow ice crystals inside. The ice crystals were looked at with spectrometers. The science would involve injecting different kinds of gasses into this ice chamber, and chemistry analysis. In other words, a good example of this would be when a comet enters our solar system and a ground-based telescope to look at it, break the spectrum down and get an understanding of the comet makeup.

Bob Walker: I went to a group which was also at NASA Ames. And I want to join that group because he needed somebody to build research equipment. And the research equipment we called ice machines. These are vacuum systems that can grow ice crystals inside. The ice crystals were looked at with spectrometers. The science would involve injecting different kinds of gasses into this ice chamber, and chemistry analysis. In other words, a good example of this would be when a comet enters our solar system and a ground-based telescope to look at it, break the spectrum down and get an understanding of the comet makeup.

For 15 years I was building research labs for these guys and specialized vacuum systems. So they can do astronomy and ask for chemistry and see whether there’s life out there or not.

The science to grow ice crystals and do chemistry with them in these vacuum systems was expensive, on the order of $150k – $200k. So the support for the vacuum system to do the science was pricey. I would build the one picture you saw and that was a complicated system. In the heart of the system, we would have what we call our refrigerator, These are commercially built Units that run off of compressed helium. It’s just the refrigerator, a little piston in there and the piston inside the Cooling system would come back and forth and as a helium at the tip of the unit. It would cool down to about four Kelvin. Then we could Inject different kinds of gasses onto the window and grow ice crystals there.

That’s how we basically get our comet. You could rotate the window around to another angle and it would face a lamp source ultraviolet, And that would simulate a comet traveling around her Sun. Then they would move that back after exposing the window to the UV light. Then they would rotate it to the path of the spectrometer. It had the biggest cooling system of all systems ever that I built at that time, very heavy. And I said, we’ve got to figure out how to get this unit in for maintenance. So I looked around and found Skyhook.

At that point. I wanted to remove this cooling system to set it in some place that we could maintain and do work with the windows.

Trey Bell: How heavy was that cooling system?

Bob Walker: It’s about 70 pounds. But none of that was in the center of the vacuum system. So it’s to lift something like that. I don’t know. You see it was about two feet long. And so you’d have to lift it completely up, entirely out of the system, before you could swing away from the instrument and you couldn’t do it by hand because you have to lean too far. That would mean leaning way over on top of the instrument and then having the muscle to lift that thing completely out.

Bob Walker: It’s about 70 pounds. But none of that was in the center of the vacuum system. So it’s to lift something like that. I don’t know. You see it was about two feet long. And so you’d have to lift it completely up, entirely out of the system, before you could swing away from the instrument and you couldn’t do it by hand because you have to lean too far. That would mean leaning way over on top of the instrument and then having the muscle to lift that thing completely out.

Trey Bell: Right. That sounds like something tough to do – and probably unsafe.

Bob Walker: Yes. Also these items have metal compressed gas lines attached to the system. They are semi flexible but this situation made it a little hard to maneuver because the gas lines were attached to the unit from the big compressor on the floor. Then I came across the Skyhook. And then I saw their mobile cart.

I called them up and said is it possible to modify the crane and the cart, so I could get a longer reach with the crane and then rotate it around and lower it down into the top of the cart, which would have a hole cut into it. I had cut away part of the top of the cart so that I could drop the cooler straight down. Then the cart would support that and that way, we could maintain it after cleaning the window and doing some maintenance on the window of the cooler. Then we could again use the lift and crank it back up to the pipe that we needed to and I swing it over, and drop it into the instrument.

Trey Bell: So it made it a heck of a lot more convenient to get the work done, right?

Bob Walker: Yeah, it’s amazing. The Skyhook.

Trey Bell: What would you estimate was the amount of work time you think you were saving by using Skyhook for that effort?

Bob Walker: Aside from the possible injury of getting it out of the instrument without Skyhook?

Trey Bell: Right.

Bob Walker: And move around because you’d have to be on the ladder to begin with, and picking up a heavy unit…

Bob Walker: And move around because you’d have to be on the ladder to begin with, and picking up a heavy unit…

Probably save an hour’s worth of work. I had it rigged so that I had special hooks to grab the Cooler right away from the lift from the Skyhook and then lift it away and anchor the cart so the unit could be worked on then returned back. All with no preparation.

Trey Bell: Anchor your cart I guess right?

Bob Walker: We had counterweights on the backside of the cart added. The back of the car had an extra lead weight that was supplied by Skyhook and mounted in the back so that I could lift it up and not worry about it tipping forward

Trey Bell: Great.

Bob Walker: Then if you’re looking at the mobile carts, they have these arms that come out from the sides to stabilize from tipping, from side to side. So as we swing the weight around, they could drop it on the table and it wouldn’t tip over

Trey Bell: Yeah, I got you. So, they tell me that you used one of these in your work And when you retired, you came to your shop at your house and you couldn’t get away from it. You had to get another one. You had to get one for the house. Tell me about that situation.

Bob Walker: The first Skyhook I bought for myself was the four-legged mobile base. It’s basically A lifting device that has four legs that come out on the floor so you can lift your devices up. We rotate it around and won’t tip anywhere. Now I also added an adapter that you can slide into the hitch of your automobile. And then, you can put the lifting device right into that hitch. I would use this in my hobby. And the hobby was building inch and a half scale locomotives that are exact replicas of the original locomotives on the railroad. We built electrical locomotives and steam locomotives and at that time, I would use a lift to pick locomotives up and move them around.

Trey Bell: Wow, that’s awesome. And it worked out fine, It works great.

Bob Walker: Yes, it’s a very easy way to fix things. Then later as my machine shop got bigger and bigger, which is now a full machine shop over the years. We have a big 14 inch lathe, and it’s very large lathe chucks. They could be as heavy as 80 pounds. In the beginning, I would have to use pieces of wood shim to support them on the bed of the lathe as I removed the nut.

Bob Walker: Yes, it’s a very easy way to fix things. Then later as my machine shop got bigger and bigger, which is now a full machine shop over the years. We have a big 14 inch lathe, and it’s very large lathe chucks. They could be as heavy as 80 pounds. In the beginning, I would have to use pieces of wood shim to support them on the bed of the lathe as I removed the nut.

Trey Bell: Right.

Bob Walker: And then slide it out. And then make a wood ramp to roll that thing down onto a table. As it was very annoying I said this is crazy, Skyhook makes a post mount.It makes it very simple to remove and so, that was the last thing I bought last year, just a short time ago. Two posts mount onto the lathe and there’s an adapter that you check up inside with a hook and then you just grab that with the lift. Crank It up off of the lathe bed and lower it onto a table

Trey Bell: Right.

Bob Walker:Let’s save 30 minutes of time right there, not to mention possible injuries especially to the back.

* Images courtesy of Bob Walker and NASA website.