New RM5 Geometry from Walter with Guided Coolant Channel and Tiger·tec ® Silver Boosts Tool Life and Improves Productivity

With its guided jet coolant targeted at the chip, providing maximum cooling and enhanced tool life, the new Walter RM5 delivers longer tool life and enhanced production.

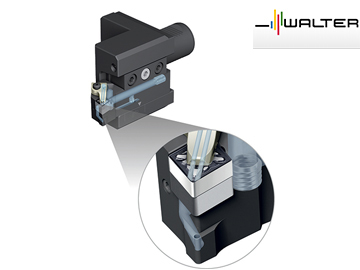

The RM5 stainless steel roughing geometry features guided twin-channel coolant targeted at the chip. This provides maximum cooling and enhanced tool life for machining ISO M stainless steels and ISO S high-temperature alloys. The Walter Precision coolant turning system and the RM5 indexable insert geometry are designed to work in concert to ensure ideal cooling. The new RM5 jet guiding geometry directs the coolant beneath the chip – and thereby even closer to the cutting edge.

For added cutting efficiency, the Walter RM5 uses Tiger·tec ® Silver PVD Al 2 O 3 cutting tool inserts in grades WSM10S, WSM20S, WSM30S, and Tiger·tec ® Silver CVD cutting tool material in WMP20S grade. The design of the cutting edges reduces notch formation and crater wear. Rigid clamp, wedge-type or lever-type clamping toolholders are available.

About Walter

Walter, a global leader in the metalworking industry with over 90 years of experience in precision cutting tools for milling, drilling, turning, boring and specialized tools, helps customers improve process reliability and increase productivity. With Regional Headquarters in Waukesha, WI, Walter markets its competence brands Walter Valenite, Walter Titex, Walter Prototyp and Walter Multiply through a strong network of distributors and field engineers across subsidiaries in the USA, Canada, Mexico, Brazil and Argentina.

For more information, visit www.walter-tools.com/us.