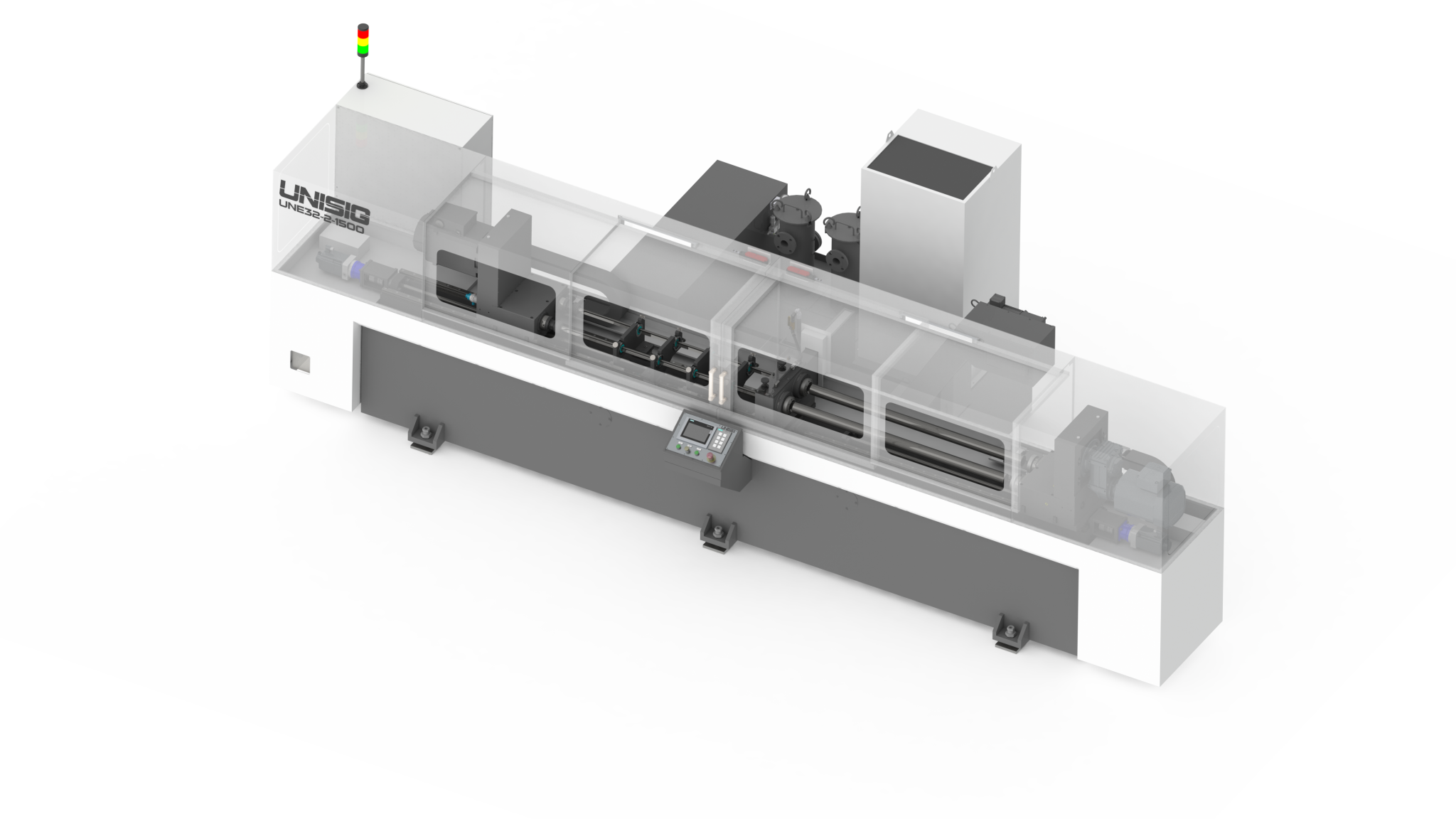

Ideal for manufacturers focused on high-volume/low-mix or low-volume/high-mix production environments, UNISIG’s next generation of UNE Series gundrilling machines delivers operational flexibility, improved performance and effortless operation. Now available, the UNE Series is engineered and designed to simplify gundrilling for all those individuals involved in a facility’s manufacturing process. The UNE Series offers gundrilling solutions that are well-suited for various industries, including firearms, automotive, medical, energy, defense and aerospace.

With five models built from two frame sizes, the UNE Series can drill hole diameters from 1.4 mm to 40 mm and depths up to 3,000 mm. The compact frame construction saves valuable floor space as well. Each machine can fit in close proximity to a shop’s existing machining center, lathe or Swiss-style machine for efficient part-processing strategies. Built with quick and easy setup in mind, the machines are also small enough to be relocated when necessary. For added flexibility to grow with future production needs, all UNE models are robot-ready, allowing shops to add a robot whenever it fits into their budgets and production schedules.

“Our feature-rich UNE machines give customers a compact gundrilling solution equipped with the ability to grow alongside them,” said Anthony Fettig, CEO of UNISIG. “A lot of job shops and OEMs have the desire to automate but lack a timeline to do so. Our UNE Series gives them gundrilling benefits for today. It also provides them with security for tomorrow, knowing that they can further improve production by adding automation.”

Several innovative features contribute to the performance and productivity of the UNE Series. The single main spindle servo motor delivers the necessary horsepower for two-spindle machines. When power is applied in single-spindle mode, however, shops can produce holes with larger diameters, increasing their capabilities and adding the potential for new business without adding a new machine.

Unlike pressure-based coolant systems, the UNE Series features a programmable flow-based coolant delivery system designed to provide the right amount of coolant to the tool’s cutting edge. The end result for the operator means they can confidently predict tool breakage and spend less downtime recovering an interrupted process.

Unlike pressure-based coolant systems, the UNE Series features a programmable flow-based coolant delivery system designed to provide the right amount of coolant to the tool’s cutting edge. The end result for the operator means they can confidently predict tool breakage and spend less downtime recovering an interrupted process.

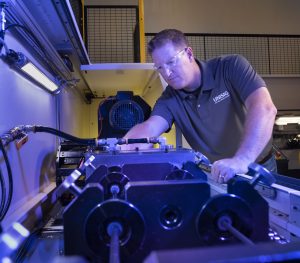

Powered by Siemens, UNE Series machines feature intuitive controls that give operators a full process picture at a glance on a rich color interface with touchscreen capabilities. The control’s heavy-duty buttons also function when operators are wearing gloves.

Ergonomically designed and engineered with the building owner and operator in mind, UNE machines offer an automated door option, which can benefit companies with or without automation. “Adding an automated door eliminates the repetitive task of opening and closing machine doors,” said Anthony. “Not only does this reduce fatigue, but it improves throughput and gives the operator an opportunity to focus on adding value in other areas.”

All UNE bases are FEA optimized and machined on five sides in single setup for the highest overall precision. This allows for simplified installation with no foundation work required, and 3-point leveling on machines rated up to 1,000 mm length.

UNE Series Overview:

-

-

- Three two-spindle models available with maximum hole diameters of 12 mm, 20 mm and 32 mm. Hole diameters even greater when used in single-spindle mode

- Two single-spindle models available with maximum hole diameters of 25 mm and 40 mm

- Five rated workpiece designation options between 750 mm and 3,000 mm

- Solid-carbide, brazed and indexable gundrill tools

- Automation ready

-

UNISIG will feature the UNE Series machines along with other deep hole drilling solutions at CMTS (September 30-October 3, 2019) in Mississauga, Ontario, and at SOUTHTEC (October 22-24, 2019) in Greenville, South Carolina.

Click HERE to learn more.

About UNISIG

A world leader in the manufacturing of deep hole drilling systems, UNISIG provides comprehensive machine, tooling and automation solutions for customers around the world from its state-of-the-art production facility and headquarters in Menomonee Falls, Wisconsin. In addition to BTA, gundrilling, trepanning, skiving and multi-process CNC machines, the company offers custom-designed systems and complete process engineering, along with full customer and application support, to ensure manufacturers’ deep hole drilling success.