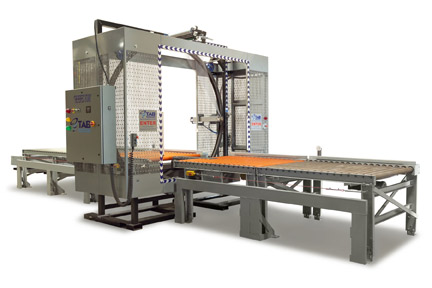

Orbital wrapper manufacturer TAB Industries, LLC has introduced multi-pallet accumulation zones as an option on its fully automated TAB Wrapper Tornado Perfect Storm wrapping systems. Developed to improve efficiency and keep lift trucks from idle time, the multi-pallet accumulation zones set modular, powered conveyors at the infeed with a proprietary sensor array that recognizes the presence of a pallet load to be wrapped. The TAB Wrapper Tornado Perfect Storm automatically feeds the pallet load from the accumulation zone onto the infeed conveyor then into the center ring for wrapping and to discharge in a continuous process, automatically adjusting the wrapping to the dimensions of the pallet load. With multiple accumulation zone extensions available, the orbital wrapping system enables lift truck operators to unload and stage multiple pallet loads for wrapping then tend to other tasks without waiting for loads in process to be wrapped and without stopping to run the system.

Available in five-foot lengths as standard and in custom-lengths to suit the dimensions of the pallet load, the multi-pallet accumulation zones may be added to the three TAB Wrapper Tornado Perfect Storm models with 100-inch, 80-inch, and 40-inch wrapping rings, and to custom size models for wrapping oversized products. The TAB Wrapper Tornado Perfect Storm automatically wraps plastic film 360 degrees around and under the pallet to create a secure, unitized load with a tight wrap that stays intact during delivery, in-plant staging and on racks in storage. The fully automated stretch-wrappers are designed and manufactured in the company’s Reading, Pennsylvania headquarters and delivered with the multi-pallet accumulation zones ready for installation.

About TAB Industries

TAB Industries has been providing warehousing, distribution and logistics services to global corporations since 2005. Currently, the company operates a 44,000 square foot modern facility and serves as the East Coast Distribution Center for DKS Steel Door and Frame Systems. They also handle warehousing for Rite Aid, Walgreens, CVS, Giant Foods and Fidelity Technology.

Drawing from their experience in warehousing and distribution and their desire to provide their customers with quality service, the team at TAB Industries developed a superior stretch wrap packaging machine that solves many of the problems faced by companies all across the country. Introduced in 2011, The TAB WRAPPER TORNADO® quickly took the packaging world by storm, offering an economical alternative to more expensive packaging machinery available from competitors.

To date, the TAB WRAPPER TORNADO® has helped countless companies reduce labor and material costs, increase productivity and virtually eliminate freight damage claims.

TAB Industries, LLC

2525 N. 12th Street

Reading, PA 19605

P: (610) 921-0012

Contact

Andy Brizek