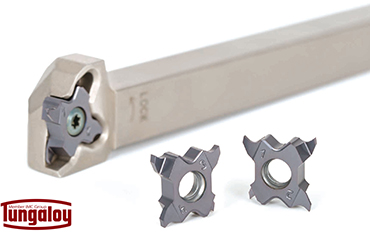

AH725 TetraMini-Cut: Added Durability for Demanding Small-Part Grooving – Inserts with Honed Cutting Edge

Tungaloy Corporation introduces an addition of the honed-edge inserts to the AH725 TetraMini-Cut insert series, which adds extra durability on the cutting edge for high-precision and high-quality grooving.

TetraMini-Cut’s ground insert, with 4 corners, is not only economical but also perfect for high-precision and high-quality machining of small parts. The uniquely designed insert pocket protects unused corners from chip damage during machining, thus assuring the usage of every corner of each insert. A unique clamping system provides high rigidity and excellent index repeatability. It is also capable of undercutting the shaft along a flange wall. The insert screw that can be tightened either from the front or the back of the toolholder which simplifies the operation when mounted in a Swiss lathe.

The cutting edge on this AH725 PVD grade insert is honed to increase toughness against chipping. To complement the sharp-edged SH725 insert, which is already on the market, the honed-edge AH725 insert is an ideal insert to improve stability in high-load machining, such as roughing, high-feed cutting, and interrupted cutting.

Main Features:

- The honed cutting edge on AH725 inserts is tougher and more stable in machining under a heavy cutting load.

- Economical 4-cornered insert

- Innovative clamping system for high rigidity and tool durability

- Uniquely designed insert pocket that protects unused corners from chip damage during use

- Capable of undercutting and finishing a flange wall at the same time in grooving on the shaft along the flange wall

- Both grooving and threading inserts are available

Insert: 28 items

ABOUT TUNGALOY AMERICA, INC.

Since its inception in the 1930’s when it was Japan’s first company to develop a cemented carbide, Tungaloy has a long history of excellence in the development of materials for metal cutting tools and innovative industrial products. The diverse range of products, including metal cutting tools, such as indexable inserts and steel products, wear resistant tools, civil engineering tools, and friction materials, are all based upon Tungaloy’s expertise in powder metallurgy. Tungaloy provides customers with products that serve as industry benchmarks. The goal is to improve customer’s productivity and cycle time to help reduce their overall costs and increase profitability.

For more information, please visit www.tungaloyamerica.com.