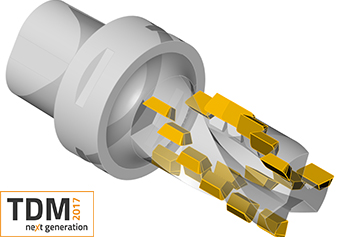

TDM Next Generation Merges Existing Software Lines; Debut at IMTS

Two years ago, Tübingen, Germany-based software company TDM Systems GmbH began setting up its Tool Lifecycle Management strategy. Now it is taking the logical next step. The new generation of software, TDM next generation, enables both entry-level options and highly integrated, global system integrations. TDM next generation features enhanced performance, worldwide networking and easy scalability, helping users implement their Industrie 4.0 requirements. TDM next generation will debut in September at IMTS in Chicago.

TDM next generation will be the state-of-the-art, highly evolved platform which will be capable of handling the operation of all existing TDM modules as well as TDM Global Line modules simultaneously. It now allows customers to completely overhaul and update their TDM software without a complicated system change. The conversion from the previous 2-tier architecture to today’s 3-tier architecture will increase both performance and process reliability while simultaneously reducing installation and service effort. Additional advantages will include simplified interface handling, easy use of on-demand and browser-based solutions and the combined use of standard and engineering solutions. The customers will find a solution tailored to their individual needs.

Safeguards in place for investments in previous applications

In talking about the benefits of TDM next generation, Eugen Bollinger, Sales Manager at TDM Systems, says, “Switching to TDM next generation provides customers with a complete modernization of their TDM-system with the least possible time and expense. The new architecture makes its applications perform better, both locally and across plants, and more fit for the future.” Bollinger also emphasizes, “We’re always focused on the customer, so we place special importance on ensuring that our customers’ investments are secure and that they can continue to use the modules they have. And we simply couldn’t be more excited about the new features in our software.”

At IMTS 2016, which will take place in Chicago from September 12 to 17, 2016, TDM Systems will feature TDM next generation at its own booth (E-3264) and at the booths of Walter USA (W-1700) and Parlec Inc. (W-2300).

Additional information about the new software generation:

First-class graphical 3D tool assembling

TDMsearch: The new innovative standard for tool searches

TDMcheck: Analyses data and processes in TDM and suggests potential improvements

Intelligent data concept: New data can be imported independently of the software version, ensuring maximum flexibility

TDMimport: Targeted, automated import of tool data from a variety of sources, possible both from external systems and from legacy databases.

About TDM Systems

Tübingen-based TDM Systems GmbH has been the leading provider for Tool Data Management for the metal cutting industry for over 25 years. With the tool lifecycle management strategy, TDM Systems is focusing specifically on process optimization through optimal tool planning and provisioning. Creating and editing tool data and graphics, integrating tool expertise and 3D graphics into the CAM engineering, and organizing the complete tool cycle at the shop floor level are the three core competencies of TDM Systems and the pillars of the TLM strategy. As a center of expertise within the Sandvik Group, TDM Systems draws on the experience of various tool manufacturers when developing its software products.

For more information, please visit www.tdmsystems.com.