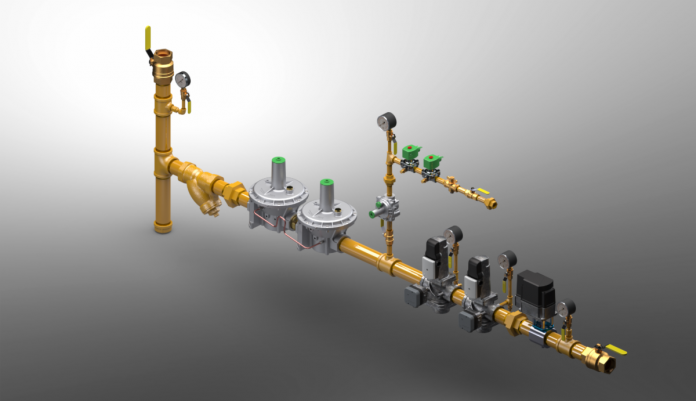

Rockford Systems, LLC. today launched its Stallion Quick Ship Program (QSP), a best-in-class fulfillment program that provides fast delivery of valve safety trains, also referred to as “gas trains” or “fuel trains,” to improve organizational planning, productivity and profitability. Stallion QSP leverages the company’s infrastructure, local presence and commitment to service to help customers avoid downtime, stay on schedule, respond to the unexpected, and control costs in today’s challenging environment.

“Valve safety trains are often the last element engineered and ordered, yet among the first needed for production, creating a production bottleneck. If your supplier is late, your equipment delivery further suffers,” said Bob Sanderson, Director of Business Development for Rockford Systems Combustion Safety. “Stallion eliminates bottlenecks so that an organization will have the combustion safety equipment it needs in a matter of days.”

The Stallion QSP is a simple and dependable way to have the most popular combustion safety products shipped to the facility quickly. With over 60,000 pre-engineered solutions to choose from – all of which are stocked and assembled in the Midwest and comply with applicable North American safety codes – Rockford Systems can supply or replace an entire valve safety train in as little as seven days. Service representatives will help identify the correct part or product, evaluate viable options, and streamline the order process.

Three Quick & Easy Options

Rockford Systems offers three shipping options to get the valve safety train products and services organizations need, when they need them:

Stallion QSP – 1 Week Delivery: pre-engineered valve safety trains up to 2″

Standard Delivery – Under 4 Weeks Delivery: pre-engineered valve safety trains up to 4″

Best-In-Class Delivery – Customized, build-to-spec valve safety trains.

Rockford Systems valve safety trains control the flow of fuel into and out of heat treating equipment, such as industrial furnaces, ovens, dryers and boilers, making them a crucial component in assuring operational safety and energy efficiency. Owing to the presence of hazardous vapors and gases in valve trains, a poorly designed or unmaintained unit can lead to explosions, fires, asphyxia and burns. For that reason, Rockford Systems valve trains are ventless and designed to be compliant with NFPA, NEMA, CSA, UL and FM globally-recognized safety standards.

To order, call 1-800-922-7533 or email customerservice@rockfordsystems.com.

ABOUT ROCKFORD SYSTEMS, LLC

Headquartered in Rockford, Illinois, Rockford Systems, LLC delivers engineered, industrial plant safety solutions for organizations using metalworking, automation, material handling or thermal processing in their operations. Since 1971, Rockford Systems has specialized in the design and installation of safeguarding systems for industrial fabrication equipment, manufacturing systems and robotics cells that meet or exceed applicable safety regulations and standards. Today Rockford Systems offers an unparalleled industrial turnkey safety solution portfolio that also includes consulting, inspections, advanced technologies and combustion safety solutions, further underscoring its commitment to total plant safety. These combined risk reduction solutions enable organizations to dramatically improve compliance and worker safety without disrupting productivity.