OPEN MIND Technologies AG, a leading developer of CAD/CAM software solutions worldwide, announced it offers an ADDITIVE Manufacturing capability option in hyperMILL® CAM software to support 3D printing/ additive processes. hyperMILL® together with ADDITIVE Manufacturing also provides efficient hybrid processing with simultaneous additive and subtractive processing on one machine.

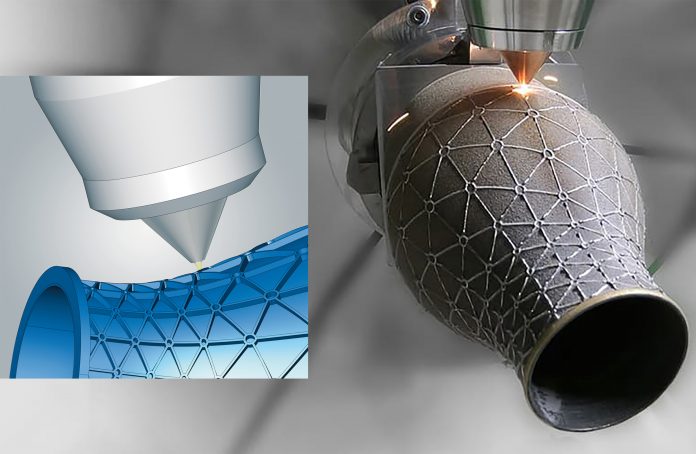

For highly complex 5-axis simultaneous processing, hyperMILL® ADDITIVE Manufacturing enables an array of flexible options for Directed Energy Deposition processes (DED) and Wire Arc Additive Manufacturing (WAAM). Both laser-based powder nozzle machining heads and WAAM can be controlled using hyperMILL® ADDITIVE Manufacturing for selective material deposition, as well as conveniently programmed and automatically simulated for collision avoidance.

Mr. Alan Levine, Managing Director of OPEN MIND Technologies USA, Inc. said, “As an early adopter of driving forward the implementation of integrated process chains, OPEN MIND has optimized hyperMILL® ADDITIVE Manufacturing technology to boost the efficiency, precision and process reliability of additive and hybrid manufacturing.”

Using Powder Bed Fusion (PBF) and any necessary rework, hyperMILL® supports the full potential of additive manufacturing. “If 3D-printed parts do not have the desired surface finish, or has support structures that have to be removed, the parts, including hard-to-reach areas, can be machined after being printed using 5-axis cutting processes,” Levine said.

hyperMILL® now enables users to perfectly program the cladding and milling together. True-to-detail additive and subtractive simulation as well as stock tracking between the individual process steps guarantee the greatest possible reliability.

Key additive applications include repair of damaged components, cladding of additional surface skins, or creation of new components from a substrate. This also creates totally new options for combining different materials, such as when high-quality material layers have to be applied to carrier materials.

About OPEN MIND Technologies AG

Headquartered in Germany, OPEN MIND is one of the world’s leading developers of powerful CAD/CAM solutions for machine and controller-independent programming. The company develops optimized CAD/CAM solutions that include many innovative features unavailable elsewhere, to deliver significantly higher performance in both programming and machining. Strategies such as 2.5D, 3D, as well as 5-axis milling, mill/ turning, and machining operations such as HSC and HPC, are efficiently designed into the hyperMILL® CAM system, providing maximum user benefit and compatibility with all current CAD solutions and extensive programming automation. OPEN MIND strives to be the best, most innovative CAD/CAM developer in the world, and has earned the top five ranking in the CAD/CAM industry according to the 2019 NC Market Analysis Report by CIMdata. OPEN MIND CAD/CAM solutions meet and exceed the requirements of the most demanding industries such as automotive, tool and mold manufacturing, production machining, medical, job shops, energy and aerospace industries, and is represented in all key markets of Asia, Europe and the Americas. OPEN MIND is a Mensch und Maschine Company.