OPEN MIND Technologies AG, a leading developer of CAD/CAM software solutions worldwide, has introduced hyperMILL® 2019.2, a new version of its advanced, comprehensive CAD/CAM software suite. The latest hyperMILL® software has a range of new features including high-precision 3D finishing, 5-axis tangent machining, high-performance turning, and new CAD-for-CAM technologies.

“We are pleased to offer our CAM customers with even more powerful finishing, 5-Axis and turning strategies,” said Mr. Alan Levine, Managing Director of OPEN MIND Technologies USA, Inc. “In addition, we have improved programming process times, and have also integrated CAD utilities directly into some CAM strategies.”

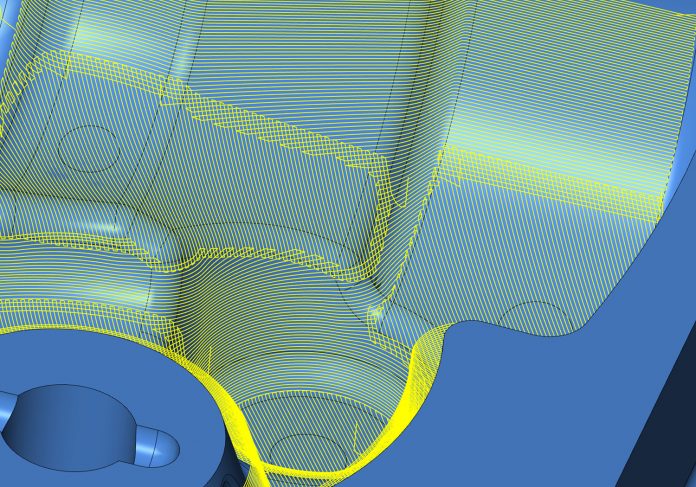

When using the 3D shape Z-level finishing cycle, hyperMILL® 2019.2 now offers a “high precision surface mode” option that ensures ultra-smooth surfaces with tolerances in the micron range. This saves time on post-machining finishing processes, especially for mold makers. The “Smooth overlap” function also improves surface finish and is available in many cycles. The transition regions for steep and shallow machining have a small overlap including a slightly lifted cutter, resulting in perfect finishes with imperceptible transitions.

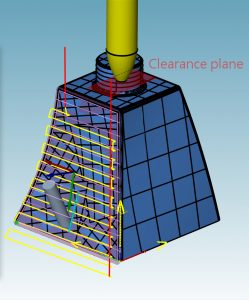

In hyperMILL® 2019.2, the hyperCAD®-S “Global fitting” function is directly integrated into the CAM strategy for 5-Axis tangent machining. With this function, multiple faces can be joined into one face with a controlled ISO orientation. The principle of using CAD elements for CAM programming is also applied for example, to an automatic face extension where the bounding surfaces are automatically extended during programming to improve the edges of the machined surfaces. These dedicated CAD utilities streamline CAM programming and provide tested and proven methodologies.

In the previous version of hyperMILL® MAXX Machining, turn-roughing was implemented with trochoidal toolpaths. Now version 2019.2 offers even greater process reliability for high-performance turning by providing tool life monitoring which restricts tool use by the distance covered, the number of toolpaths, or a time limit. If the defined limit is reached, a retract macro is generated automatically and the job ends.

OPEN MIND has further enhanced its feature and macro technology in the new version to enable more secure and simpler programming. Full-text searching is now available in the macro database and users can define machine and material groups as defaults to make it easier to select macros.

Hole feature linking enables CAD feature model changes to automatically transfer to hyperMILL®. Since design changes in CAD are associatively linked with the CAM, users can quickly and securely make updates.

Helpful when working with very large parts, hyperCAD®-S calculates the workpiece mass and center of mass with a material definition including for solid, mesh and stock models. Also, the “Undercut” function makes it possible to detect undercut areas on components quickly and reliably. In addition, the new “local curvature” analysis function makes it possible to detect curvature radii on components. The minimum curvature radius, which often plays the biggest role, is output immediately, and the best possible lead angles or tool radii for machining curved faces can be determined. This can be beneficial when planning hyperMILL MAXX Machining strategies that use conical barrel cutters (also known as circle segment tools).

About OPEN MIND Technologies AG

Headquartered in Germany, OPEN MIND is one of the world’s leading developers of powerful CAD/CAM solutions for machine and controller-independent programming. The company develops optimized CAD/CAM solutions that include many innovative features unavailable elsewhere, to deliver significantly higher performance in both programming and machining. Strategies such as 2.5D, 3D, as well as 5-axis milling, mill/ turning, and machining operations such as HSC and HPC, are efficiently designed into the hyperMILL® CAM system, providing maximum user benefit and compatibility with all current CAD solutions and extensive programming automation. OPEN MIND strives to be the best, most innovative CAD/CAM developer in the world, and has earned the top five ranking in the CAD/CAM industry according to the 2018 NC Market Analysis Report by CIMdata. OPEN MIND CAD/CAM solutions meet and exceed the requirements of the most demanding industries such as automotive, tool and mold manufacturing, production machining, medical, job shops, energy and aerospace industries, and is represented in all key markets of Asia, Europe and the Americas.

OPEN MIND is a Mensch und Maschine Company.