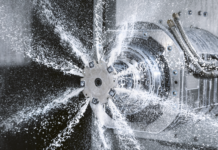

Walter has introduced the M5137 Xtra·tec® XT shoulder milling cutter. It features six cutting edges, approach angles of exactly 90°, positive geometry, and two pitches for different applications. The cutter’s exact 90° lead angle eliminates the need for additional finishing operations and its strong, double-sided indexable inserts boost process reliability.

This milling cutter can be used universally for steel, stainless steels, cast iron and difficult-to-machine materials, in face, shoulder, ramping, pocket, and circular interpolation milling operations. Available in diameters of 32-100 mm, a maximum depth of cut of 5 or 8 mm), with Weldon shank or shell mill mount interface.

The fully sintered circumference inserts provide maximum cost efficiency and design features for easy cutting geometry. Further, they boast reduced operating costs thanks to their Tiger·tec® coating and being double-sided. This translates to simple tool selection and low cutting material costs, and highly cost-effective operation due to low unit costs.

About Walter

Walter, a global leader in the metalworking industry for over 100 years, offers a wide range of precision tools for milling, turning, drilling and threading applications. The company helps customers in the aviation and aerospace industries, automotive, energy, and general industry improve process reliability and increase productivity. As an innovative partner capable of creating digital process solutions for optimal efficiency, Walter is pioneering Industry 4.0 throughout the machining industry. With Regional Headquarters in Waukesha, WI, Walter markets its competence brands Walter, Walter Titex, Walter Prototyp and Walter Multiply through a network of channel partners and field engineers across the USA, Canada, Mexico and Brazil.