It’s another first from Prima Power Laserdyne – SmartPerf™ the application inspired tool for programming and laser drilling of simple to complex patterns of holes in linear and cylindrical paths in 2D and 3D parts.

SmartPerf ensures higher quality holes, both in terms of metallurgy and geometry, with the benefit of reduced cycle time for “on-the-fly” laser drilling. Higher productivity is accomplished by eliminating the need for acceleration and deceleration at each hole location when comparing “on-the-fly” laser drilling to standard percussion laser drilling.

On-the-fly drilling with SmartPerf is a proven process for percussion drilling small diameter (0.2 to 0.6 mm) holes in turbine engine combustors. All of the Prima Power Laserdyne Nd:YAG and fiber laser systems can drill these holes at steep angles and in difficult-to-machine materials. Thousands of holes can be produced quickly over a 3D surface in a single setup.

SmartPerf is also used for producing patterns of holes involving both trepanning (cutting) and standard percussion drilling (move to a location and create the hole by delivering a sequence of pulses) in addition to on-the-fly drilling.

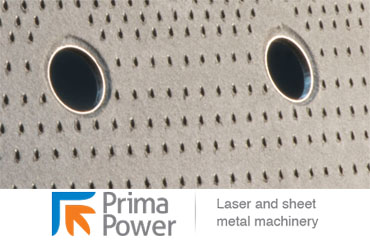

With SmartPerf, complex patterns involving non-uniform hole spacing and varying hole size are easily produced. Common applications involve drilling a pattern around a pre-existing machined feature (PHOTO ABOVE) and creating custom spray patterns based on an array of non-uniformly spaced, sized, and shaped holes.

Quality is enhanced because SmartPerf reduces heat input to the workpiece. This is especially important when laser drilling thermal barrier and other coated high temperature alloy metals. When used in conjunction with Laserdyne SmartPierce, results are even more effective since the process produces less debris, less heat and less part distortion.

SmartPerf broadens the applications for which laser drilling is economical. It enables new laser drilling applications such as fuel filters, noise abatement panels and spinnerets used for the production of synthetic fibers. The new control feature is also useful for laser texturing.

SmartPerf is one of an entire suite of SmartTechniques™ available in all Laserdyne system models. Users can be confident that their laser processes are more productive, yield higher quality and are more robust. The SmartTechnique™ suite also includes SmartPierce™, SmartRamp™, SmartSense™, SmartShield™ and SmartStop™. With Laserdyne’s advanced, integrated control of all laser, motion, and process sensors along with these unique processing techniques, users will achieve ground breaking results.

Prima Power | North America, Inc.

555 West Algonquin Road

Arlington Heights, IL 60005 USA

P: (847) 952-6500

F: (847) 952-6530