Enables Single-Step Machining of Complex Features

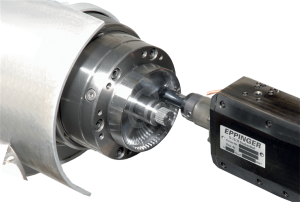

The EPPINGER Shaping Attachment, recently introduced by EXSYS Tool, Inc., enables single-step machining of a wide variety of difficult-to-cut features including grooves, chamfers, Torx screw heads, splines and gear teeth. In addition, permanent grease lubrication of the attachment’s bearing surfaces helps reduce wear and tear on the machine tools that employ the device.

The EPPINGER Shaping Attachment, recently introduced by EXSYS Tool, Inc., enables single-step machining of a wide variety of difficult-to-cut features including grooves, chamfers, Torx screw heads, splines and gear teeth. In addition, permanent grease lubrication of the attachment’s bearing surfaces helps reduce wear and tear on the machine tools that employ the device.

The Shaping Attachment is engineered for productive and efficient operation. In use, it drives the cutter into the workpiece in the Z-axis at cutting speeds up to 1,000 strokes per minute. At the end of each stroke an integrated lift-off mechanism returns the cutter to the starting position without drag, protecting the surface finish of the component and the cutting edge of the tool. With a working stroke of 1.3″ (32 mm) and maximum feed of 0.006″ (0.15 mm) per stroke, the attachment can produce maximum groove widths of 0.31″ – 0.34″ (8-10 mm).

The Shaping Attachment’s capability to machine difficult features in a single setup increases production throughput, while its permanent lubrication, lift-off mechanism, and rigidity minimize machine tool wear and downtime that can result from performing tough gearmaking-type operations.

For more information, please visit:

www.exsys-tool.com

or contact:

info@exsys-tool.com

800.397.9748

About EXSYS Tool, Inc.

Founded in 1987, EXSYS Tool, Inc. provides high-precision rotary and static-fixed tool holder solutions for CNC turning centers. The company is the exclusive importer of German-made EPPINGER tooling, including the revolutionary PRECI-FLEX® adapter system for lathe tooling changeovers. With headquarters near Tampa, Fla., and support offices in California, Canada and Mexico, EXSYS effectively offers over 22,000 different types of tool holders, gold standard tooling repair and applications expertise to manufacturers throughout North America.