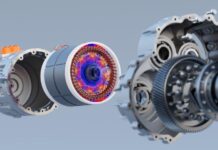

Make deep hole operations productive and reduce the risk of scrapping large, expensive workpieces with the new GL threading and grooving heads for Steadyline® ø1″ (25 mm)-diameter turning and boring bars from Seco Tools. The new heads extend the range of GL Heads and Steadyline® bars, increase production accuracy, improve surface finishes and reduce down time from insert indexing and head changing.

Offered in right-hand and left-hand versions, these compact new heads provide the high repeatability of the Seco GL25 connection. The GL connection’s optimized wall thickness achieves centering accuracy and probing repeatability within 5 μm, and the connection provides for increased operational versatility and faster, easier tool changes. Seco Tools designed these new GL25 threading heads for integration with Seco Jetstream Tooling® high-pressure coolant capability.

On small and large holes, Steadyline® turning bars facilitate stable, easy turning and boring to depths up to 10xD with the industry’s most effective vibration damping system. For operations inside deep hole diameters as small as 1.181″ (30 mm), shops can take advantage of the system’s reach/overhang capabilities and highly effective anti-vibration technology.

About Seco Tools

Seco Tools, LLC Headquartered in Fagersta, Sweden and present in more than 75 countries, Seco Tools is a leading global provider of metal cutting solutions for milling, stationary tools, holemaking and tooling systems. For more than 80 years, the company has provided the technologies, processes and support that manufacturers depend on for maximum productivity and profitability.