UNISIG Presents Deep Hole Drilling Innovations and Applications at CMTS 2017

UNISIG will spotlight its comprehensive line of deep hole drilling innovations at the  Canadian Manufacturing Technology Show, held at the International Centre in Mississauga, Ontario from September 25-28. Located in booth #1337, UNISIG will also consult with attendees on how best to incorporate deep hole drilling into their operations.

Canadian Manufacturing Technology Show, held at the International Centre in Mississauga, Ontario from September 25-28. Located in booth #1337, UNISIG will also consult with attendees on how best to incorporate deep hole drilling into their operations.

UNISIG develops comprehensive solutions for any deep hole drilling application. The company’s broad product portfolio addresses applications in practically every key industry segment and is complemented by UNISIG’s full turnkey approach that includes machinery, tooling and automation.

“Our customers come from every area of industry and range from specialty shops that have focused exclusively on deep hole drilling to those who have just started to take on work that would justify the investment of a dedicated machine,” said Anthony Fettig, CEO of UNISIG. “We work with every customer to ensure they have the right technology for their specific needs and help them seamlessly implement it into their production operations.”

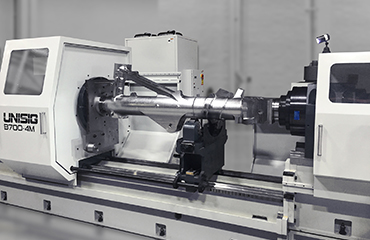

One example of UNISIG’s innovative technology is the new B700 Drop Bed machine. The company engineered it to effectively generate the critical, high-precision features on large and irregularly shaped aerospace components such as landing gear struts. Conversely, the extreme flexibility of the machine allows it to also process medium sized, more uniform shaped workpieces with minimal changeover time.

The B700 offers an expansive working range with its servo programmable workpiece headstock capability, yet it sports a streamlined overall footprint that makes for space-saving installations and enhanced ergonomics. This is unlike other comparable deep hole drilling machines that are often inflexible dedicated systems as well as oversized and cumbersome.

The B700 machine expands UNISIG’s extensive B-series line designed for on-center drilling of cylindrical workpieces in applications such as aerospace, defense and oil & gas. In addition to standard BTA drilling methods, these machines are also capable of counterboring, trepanning and skiving as well as roller burnishing processes. The machines easily maintain the extremely tight tolerance requirement of manufacturers in these and other industries.

UNISIG engineers and manufactures all its machines in the United States for its global customer base. Upon machine installation, the company provides its customers with comprehensive training that involves machine operation and process optimization, as well as attentive post-installation service and extended training.

About UNISIG

Headquartered in Menomonee Falls, Wisconsin, UNISIG is a world leader in the manufacture of deep-hole drilling systems and technologies for precision-focused metalcutting industries, including aerospace, automotive, energy and medical. A state-of-the-art production facility and reliable network of local suppliers allow the company to design and manufacture its BTA, gundrilling, trepanning and skiving machines as well as its tooling solutions and automation in the United States. For more information on UNISIG, visit UNISIG.com or follow the company on LinkedIn and Twitter (@UNISIG).