Cecchini says, “A company like Trenton, with its good reputation, is a real landmark in this area. Most of the manufacturing is done in-house [and] we take care of many different client requests.” Using VICIVISON Measuring Machines enables them to be one step ahead in a competitive market. Cecchini says, “…in terms of production and quality, we always try to have the best equipment available [and] this machine can be used to carry out inspection on an entire line.”

The accuracy and simplicity that the VICIVISION Measuring Machine provides, allows Trenton to better prioritize their time to more important tasks for their operational needs.

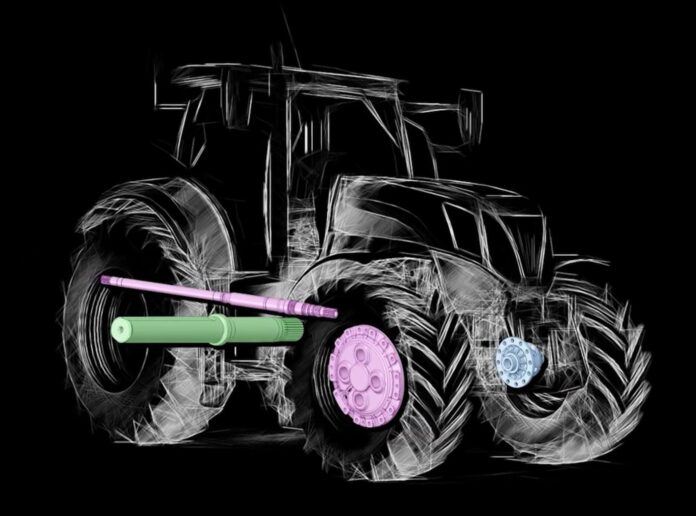

Trenton uses a M2018 Techno with a Touchprobe to measure the many different parts they make in their manufacturing line. Cecchini says, “We can produce parts up to 1500 mm in length and inspect them on the Vici machine [using] the Touchprobe to measure keyway slots and planes. This machine measures parts 2000mm in length and 180mm in width giving Trenton the versatility they need in measuring the mechanical components they create.

OPTICAL AND TACTILE COMBINATION ON THE SAME DEVICE

Investing in a VICIVISION machine comes from the company’s decision to combine quantity and quality within production, and that’s the focus on this combination that makes Trenton a cutting-edge company, capable of manufacturing many parts, from facing and centering to grinding.

Catching inaccuracies early can reduce the amount of waste, therefore saving a significant amount of time and money.

The accuracy and simplicity that the VICIVISION Measuring Machine provides, allows Trenton to better prioritize their time to more important tasks for their operational needs. Massimo of Quality Control says “It really helps to know we are starting production off on the right foot, in such a short set up time.”

He goes on to explain that one can measure a part in 93 seconds, and the results indicate the validity of the part being measured. The tolerances for each measurement are defined by either green or red line indicating the accuracy of the measurements for the product produced. Catching inaccuracies early can reduce the amount of waste, therefore saving a significant amount of time and money.

…the decision to have VICIVISON Measuring Machine involved in the process is a great investment that ensures efficiency and accuracy in the process of making quality products.

Trenton has had a VICIVISION Measuring Machine for a year and over time they have created many new programs giving them the ability to increase the amount of parts that are inspected. This intuitive machine allows for innovation in the process of the entire production and with new technologies it means that Trenton is better able to anticipate their customer’s needs.

As Trenton continues to manufacture the many different parts in their production line, they know the decision to have VICIVISON Measuring Machine involved in the process is a great investment that ensures efficiency and accuracy in the process of making quality products.