InduSuite recently introduced WeldCloud Assembly, a cloud-based digital application that provides welding professionals with a completely new level of production traceability. Key functions include the ability to record weld session data directly from a welding power source and enable immediate comparison to Weld Procedure Specification (WPS). If a weld is outside the WPS, the system can send an alert so that users can immediately repair the weld and begin identifying the root cause of problems.

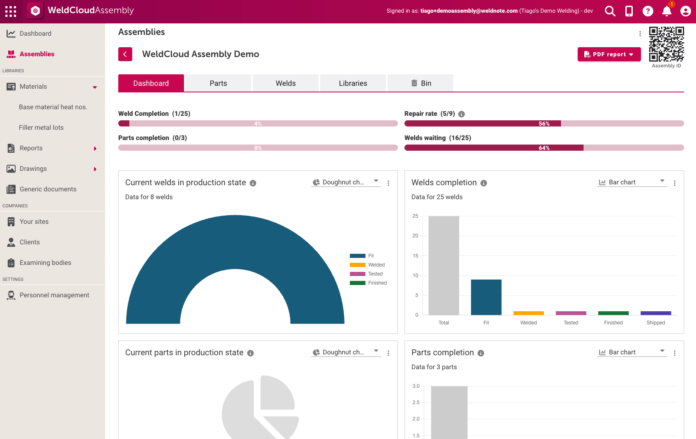

The new app offers supervisors and managers a Global Dashboard that provides insight into four areas of project management: current production state of a project, percentage of welds completed, repair rate and welds waiting. WeldCloud Assembly complements the current products in the InduSuite platform including WeldCloud Notes and WeldCloud Productivity.

“WeldCloud Assembly helps companies requiring heavy documentation, compliance, traceability and accountability perform essential project management tasks with greater efficiency and accuracy,” says Tiago Pereira, InduSuite product manager. “WeldCloud Assembly will change how companies handle welding data and welding relationships.” The application made its debut in ESAB booth #B20063 at FABTECH 2023 at McCormick Place in Chicago.

Brand Agnostic Analytics

Instead of the tedious process of manually recording welding data, which is also subject to human error and tampering, WeldCloud Assembly digitizes the process for speed and accuracy. With the Universal Connector or WeldCloud-enabled power source, welding data for virtually any brand of welder can be recorded and analyzed. By capturing data and linking it to the WPS, users can give their customers greater quality confidence.

“WeldCloud Assembly will change relationships by enabling digital communication with a central, online platform,” says Pereira. “For example, it connects engineers with supervisors by enabling them to send welding instructions to their mobile devices. By communicating production status, it connects sub-contractors and production managers. By enabling weld inspectors to enter notes from the field, it connects them with QC departments.”

Weld Cloud Assembly provides a consistent production platform that is useful particularly for power generation, oil and gas, shipbuilding, structural steel and other industries with traceability requirements. The software sends all the information on each weld directly to the cloud, which can then be accessed via a computer, tablet or other mobile device. Because the information is transmitted directly from the shop floor, there is no chance for misinformation.

Saves Time, Improves Production

Weld Cloud also identifies production bottlenecks by tracking weld stages. For example, a user may learn that it has a backlog of welds that haven’t been inspected yet, which may mean the inspection process needs additional support. Additionally, Weld Cloud Assembly allows customers to track all projects, with each subcontractor, ensure weld quality and compliance, print weld reports with non-destructive testing requirements and get statistical measurements of assemblies, parts, welds, repair rates, audit logs, and full counts of all types of documents.

Weld Cloud Assembly can create detailed comparisons and graphs of customizable weld details. For example, it can show users the completion of each project phase. A color-coded graph of each weld session is also available to monitor each weld, in real time, at a glance. It identifies compliant welds in green and welds that occurred outside of the set parameters in red.

The Inspection segment of Weld Cloud Assembly is also customizable and includes testing options (e.g., visual, radiographic, ultrasonic, etc.), test status (planned or executed), all tests approved, tests failed, and location of the weld failure (base, groove, weld or heat affected zone).

“Our customers want maximum traceability on their high-profile jobs,” continues Pereira. “They want to know what is happening on the shop floor, at multiple locations, in real time so they can fix any issues immediately. Weld Cloud Assembly provides them with instant insights and greater transparency, all in an easy-to-use digital platform.”

InduSuite Portfolio

InduSuite cloud-based solutions include WeldCloud Productivity, WeldCloud Fleet, WeldCloud Notes and CutCloud for cutting data analytics. Installed InduSuite software applications include COLUMBUS CAD/CAM nesting software for automated cutting/beveling, OCTOPUZ for offline robot programming and EasyNest Online a cloud-based nesting software created in partnership with Alma (almacam.com). InduSuite applications are brand agnostic, so they can connect data, machinery and processes across a mixed fleet of welding, cutting and robotic equipment.

The InduSuite portfolio helps companies improve efficiency and quality at every step of the fabrication process, from plate to finished product. InduSuite apps do not require IT expertise. The cloud-based applications feature an intuitive interface that enables users to be up and running after about an hour of training. They function on a common platform built with state-of-the-art Microsoft Azure, the most secure and reliable cloud architecture.

About ESAB

ESAB is a world leader in fabrication technology. For more than 100 years ESAB has transformed industries built by fabricators, providing complete workflow solutions through our diverse portfolio of products from more than 40 of the most trusted brands in welding and cutting in the world. From industrial demands to repair and maintenance, innovators that shape the world rely on ESAB’s portfolio.