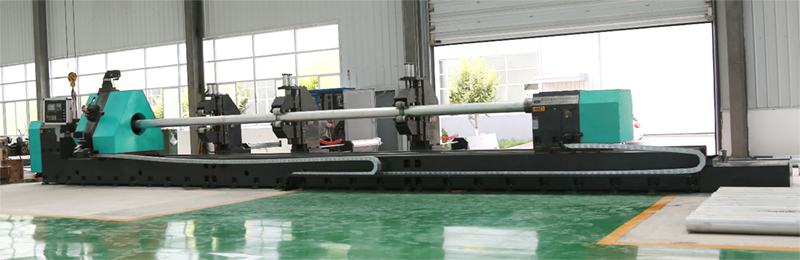

Hydrapower International, Inc., with world headquarters on Marco Island FL., a world leader in Metal Forming machinery and Pole Manufacturing technology has completed development of 2 machines which speed up production of lighting, utility and traffic signal poles. The Flow Former can also make flag poles and decorative poles with an extensive range of profiles.

The Burnisher, built on the same base, processes poles over a mandrel and the rollers raise the poles structural strength to meet ASTM specs. Various mandrels enable the Burnishing of conical and polygon poles.

The machines are controlled by Siemens 840D multi axis CNC with functions similar to machining centers but our machines do not cut metal they move it by plastic flow to create the required shapes.

Flow Former Process and Products

Flow Former Process and Products

Raw Material

Pipe or tube with various wall thicknesses. Steel, Aluminum, Stainless Steel and others.

Capacity

12” x 46’ 300mm x 15Meters

Aluminum flag poles

Steel poles tapered and fluted

Burnisher

Capacity

Up to 16” DIA X 46’ 400 mm x 15 meters

Burnish Mild Steel to Grade 50 or more

Steel and Aluminum poles.

Conical and polygons.

Some fluted.

About Hydrapower International Inc.

There are around 4,000 Hydrapower machines in use throughout the world and rarely will you find a used machine for sale. Since 1972, the company has invested in engineering and service rather than advertising. This contributes to their large volume of repeat customers. All of their machines are built to quality standards much higher than ISO-9000 requirements, and always have been. This is backed by their 5-year warranty, the highest standard in the Fabricating Equipment Industry.