Get a Grip with SMW Autoblok Pull Down Chucks

Subtle variations can make a big difference when you are clamping workpieces with a high demand for parallelism (the minimum degree of variance parallel to an origin point). That’s why SMW Autoblok‘s TSB Pull Down Chucks are designed so you can easily match the proper chuck to the job.

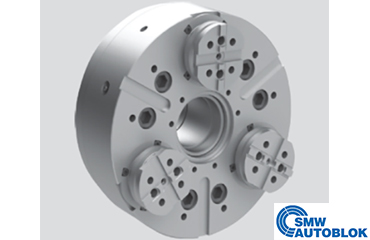

The 3-jaw chucks in the TSB series are built for superior performance. Specific features include active pull down,centrifugal force compensation, a constant grip force and a long lifetime to ensure constant workpiece quality. A through hole is incorporated to insert long workpieces and special clamping applications such as integral shaft style components or shaft mounted gear applications. This open center feature also allows for swallowing of the part to execute details on a section along its length that in the past would have to be done in an additional operation.

High productivity is standard since all TSB models are part of our Proofline® Series—which means they are fully sealed for low maintenance. The Model TSBF-C has floating base jaws to clamp raw or easily deformed workpieces. The Model TSBR-C has rigid base jaws for precise clamping on pre-machined diameters.

Starting from this high quality baseline, we added practical variations that allow you to select the TSB chuck that best meets your job requirements.

If you want all the features of the C model with the added advantage of reduced down time between short runs, the RM model allows for a quick jaw change via pallets. It also comes with floating base jaws (Model TSBF-RM) and rigid base jaws (Model TSBR-RM).

The CP models are designed to clamp shafts or chuck parts where the reference is not the outside diameter, but a center or a centering diameter. The workpiece is actively pulled down to the center point. The tailstock simply supplies the necessary force to support the workpiece. The result is an exact cylindrical and straight finished component. The Model TSBF-CP has floating base jaws and the Model TSBR-CP has rigid base jaws.

About SMW Autoblok

Autoblok Corporation was established in 1981 as a subsidiary of Autoblok of Italy, the largest power chuck manufacturer in Europe. Since 1942, Autoblok has been at the forefront of engineering and manufacturing state-of-the-art workholding, clamping and tooling solutions. The global corporate organization is dedicated to QUALITY, PRICE, TECHNICAL SUPPORT and CUSTOMER SERVICE. Our products are manufactured to the most demanding standards in the world, yet priced competitively to those products of lesser performance. Autoblok has achieved sustained global growth by providing a superior level of customer service and technical support for our application driven product line.

In 1993, Autoblok acquired SMW of Germany. The combination of these two premier manufacturing entities resulted in the most extensive product line of high quality workholding devices in the world. Now available exclusively through its subsidiaries, reps and distributors, SMW AUTOBLOK customers are ensured a consistent, single source of superior product performance, support and service.

For more information, please visit www.smwautoblok.com.