EXSYS Tool Inc., well known for its high-quality, productivity-boosting solutions for CNC turning centers, now offers those same benefits for customer milling applications as the new exclusive North America supplier of pL LEHMANN ultra-high precision rotary tables.

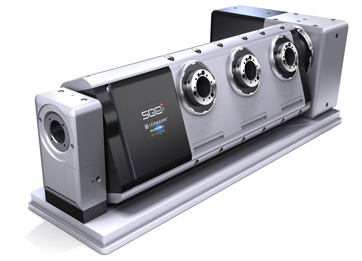

The Swiss-manufactured pL LEHMANN 500 series of modular multi-axis rotary tables allow users to upgrade a vertical

machining center to significantly increase productivity without incurring the expense of a new machine. Adaptable to nearly any workpiece or production situation, the tables are available in four basic models that can be assembled into as many as 240 different configurations. More than 20 different clamping methods and behind-the-spindle accessories that include rotary unions, special clamping cylinders and angular position measuring systems further extend the system’s adaptability.

“From day one, we have, and continue to, provide customers with more than just tools,” said Stewart Bachmann, CEO of EXSYS Tool Inc. “Our goal is to truly improve their productivity as well. This is why we’ve always limited the product lines we represent to only those that definitely outperform the competition when it comes to quality, service and immediate support responsiveness. pL LEHMANN is a company that far exceeds those criteria, which is why we are extremely proud to welcome them to the EXSYS/Eppinger brand.”

Additionally, Bachmann announced the appointment of Ivo Straessle as the company’s new pL LEHMANN product manager. As a valued team member, Straessle will also be the EXSYS/Eppinger Northeast territory manager.

Additionally, Bachmann announced the appointment of Ivo Straessle as the company’s new pL LEHMANN product manager. As a valued team member, Straessle will also be the EXSYS/Eppinger Northeast territory manager.

Compact pL Lehmann tables consume a minimum of space in the machine work envelope, facilitating optimal tool access to the workpiece. Despite their space-efficient dimensions, the tables and spindles offer strong resistance to pull-out torque and axial force while providing high levels of clamping torque. Engineered for low power consumption and light weight, the tables feature IP67 rated enclosures.

Both single-spindle and multi-spindle tables are available in 4-axis and 4/5-axis versions. Swiveling-bridge-style 4-axis tables employ the roto-FIX clamping yoke for machining of multiple parts. The tables’ backlash-free preloaded gear drives (PGD) provide both high torque and high rotation speeds, with spindles capable of 47-111 rpm and cycle times for 90 degrees of 0.34 sec. pL Lehmann 5-axis tables operate in simultaneous machining or productivity-enhancing 3+2 positioning modes.

About EXSYS Tool, Inc.:

Founded in 1987, EXSYS Tool, Inc. is the exclusive importer of German-made EPPINGER solutions, including high-precision live and fixed toolholders for CNC turning centers, modular adapter systems for quick lathe tooling changeovers and gear box solutions for a wide range of applications. The company also offers Swiss-manufactured pL LEHMANN high-precision rotary tables engineered for CNC milling machine operations.

With headquarters near Tampa, Florida, and support offices in California, Canada and Mexico, EXSYS offers a variety of different types of tool holders, gold standard tooling repair and applications expertise to manufacturers throughout North America.

For more information, please visit:

www.exsys-tool.com

Or contact:

info@exsys-tool.com