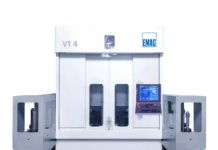

New Multi Tasking Turning Center Offers 100″ Turning Length at IMTS 2016

Doosan Machine Tools America, located in booth S-9100 at IMTS 2016, presented its latest generation of advanced multi-tasking turning centers- the PUMA SMX series. There are six models in the line, stepped in size and capabilities. Most offer the unique configuration of equally sized and powered left and right spindles plus a B-axis milling spindle. Officially launched in North America at IMTS 2016 was the new PUMA SMX 3100L tailstock model, which offers and extra-long turning length of 100 in. (2540mm).

According to Doosan Region Manager Carl Barthelson, current manufacturing trends are exemplified in this new line. “Our customers are requiring machines to have more functionality to increase efficiency, accuracy and conserve floor space. It’s common that one multi-tasking center can machine all sides of a part in one setup and replace multiple machine tools that have singular functions. The PUMA SMX series of machines fulfill all of those needs.” Mr. Barthelson also said that the new line is a reflection of Doosan’s larger product development approach, which is to research customers’ needs and provide solutions, sometimes with specific niche applications in mind. “For example, the new PUMA SMX 3100L model we are introducing at IMTS has the new longer 100-inch turning length dimension as a direct result of listening to our customers. Many manufacturers in the aerospace and power generation markets need that extra capacity of their parts. Likewise for the medical industry, several companies in that market liked what we were doing in multi-tasking, but didn’t need such large equipment. So, we now have models that are ideal for medical and other smaller parts.”

In addition to the highlighted Z-axis travel of 100 inches (2540mm), other key specifications of the PUMA SMX 3100L include a 4-inch bar capacity and a maximum turning diameter of 26 inches (600mm) to support the turning of long, large-diameter workpieces. A range of chuck sizes can be accommodated. The main spindle is powered by 40 hp, 3,000 rpm motors. The Y-axis travel is 11.8 inches (300mm) and features the B-axis 12,000 rpm mulling spidle that has a 0.0001-degree incremental accuracy control functuion, and programmable C-axes. The Y-axis machining area has been maximized through an orthogonal design structure.

As with all of Doosan’s machine tools, special features and materials have been designed and built-in aimed at high rigidity, accuracy, thermal compensation, and optimal ergonomics. For example, the company uses the Finite Element Method in structural design and minimizes thermal distortion with an oil cooler and an accuracy control feature based on multiple thermal compensation functions. In addition to using robust materials for mass, high rigidity and precision are also achieved through the use of roller-type linear motion components on all guideways. For operator convenience, the SMX machines allow tools to be loaded in the 80-tool magazine from the front, rather than from the side or rear as is typical on other brands. The Fanuc 31i-B5 control panel moves from side-to-side swivels, and its height may be adjusted for the operator’s comfort and preference.

This new PUMA-SMX series unveiled at IMTS is just one of Doosan Machine Tool America’s 6″ to 15″ chuck size multi-tasking machines that are available and can be matched to specific customer requirements.

About Doosan

Doosan Machine Tools started its business in 1976 and built its Changwon factory by 1979. Production of our first 1,000 units was achieved in 1980 after the introduction of the PUMA 10 series which was developed using our exclusive technologies.

We are very proud of our achievements in supporting the development of key industries and the fact that we are now providing products to leading companies around the globe. I would like to thank all our customers for supporting such achievements through their sincere support and advice.

For more information, please visit www.doosanmachinetools.com.