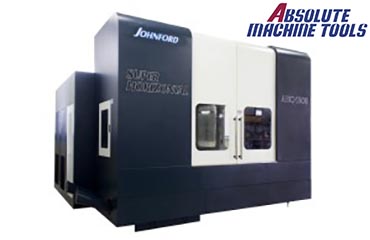

Johnford AHC-1600 Moving Column Combination Table at

IMTS 2016

Absolute Machine Tool will present the Johnford AHC-1600 at IMTS 2016 (Booth #S-8536).

The newly introduced horizontal machining center lends itself to applications across many industries but is particularly useful for aerospace. According to one of Absolute Machine Tool’s customers, Tony Brandt of Brandt’s Custom Machining (Mansfield, Ohio) the Johnford AHC-1600 is “every job shops’ dream machine.”

The HMC features a combination 63” x 32” flat table with an 800mm full B-axis

built-in rotary table. With standard accessories, this rigid 35 HP horizontal machining

center weighs in at 44,000 lbs. of Meehanite cast iron. The design features a

moving column for the Z-axis and a moving table for the X-axis only. This is superior to a moving table / fixed column design, allowing for maximum rigidity, better accuracy, and full support of the table over the complete X-axis travel. The moving column design eliminates the need for outriggers or outboard supportive ways to support high table loads. The X-axis is fully supported by the base with no table overhang.

Other features include precision-ground and induction- hardened box ways in X, Y, and Z axes. All mating surfaces are coated with Turcite-B and hand scraped for fit. Large (2.0”) diameter, pre-tensioned ballscrews and powerful servomotors provide highly accurate positioning.

The standard 6000 RPM 50 taper spindle delivers robust performance throughout the

RPM range. A 35HP main motor with two-speed gear drive ensures outstanding

cutting performance at any spindle speed. Both the spindle and gearbox are oil-cooled for

minimal thermal growth. Standard features include a heavy-duty 40 tool arm type ATC

that is stand-alone and separated from the machine for easy maintenance, a chip

removal system consisting of 4 screw type conveyors (2 parallel with the Z-axis, 2

parallel with the X-axis), a high volume coolant system, full machine enclosure guarding

to contain all chips and coolant, and a combination 63” x 32” flat table with a 32”

(800mm) .001° full B-axis built-in rotary table. X-axis longitudinal travel is 63” (72”, 79”,

118” optional), Y-axis vertical travel is 50”, and Z-axis column travel is 40” with a base

weight of 44,000 pounds.

About Absolute Machine Tool

Absolute Machine Tools was founded in 1988 and has become a leading importer and distributor of CNC machine tools. Absolute has provided advanced metalworking solutions and comprehensive services for production machining, mold/die machining, high-speed machining, conventional turning, Swiss turning, wire EDM, die sinkers, hole drillers, and deep hole drilling/finishing.

For nearly 30 years we have been helping machine shops and manufacturing facilities improve their production processes to be more competitive in today’s tough global environment. Absolute has worked with several of our principal machine tool partners since the beginning to offer some of the best most reliable machine tools in the industry. Long-term partnerships between OEMs and distributors seem to be a novelty of the past.

Absolute is proud to declare that we’ve been representing Johnford for nearly 30 years, Tongtai and You Ji for 20 years, AccuteX EDM for 10 years, and Nexturn for 5 years. We are are also proud to say that not one of our partners is new to the machine tool industry, like so many others in recent years. Because of this, Absolute Machine Tools has been able to build an exemplary reputation based on applications engineering, service, and customer support, along with comprehensive training, effective preventive maintenance programs, and parts inventory. Absolute Machine Tools has four technical centers: Lorain and Mason Ohio, Livonia, Michigan, and Elgin, Illinois. Go with the “A” Team!

For more information, visit www.absolutemachine.com.