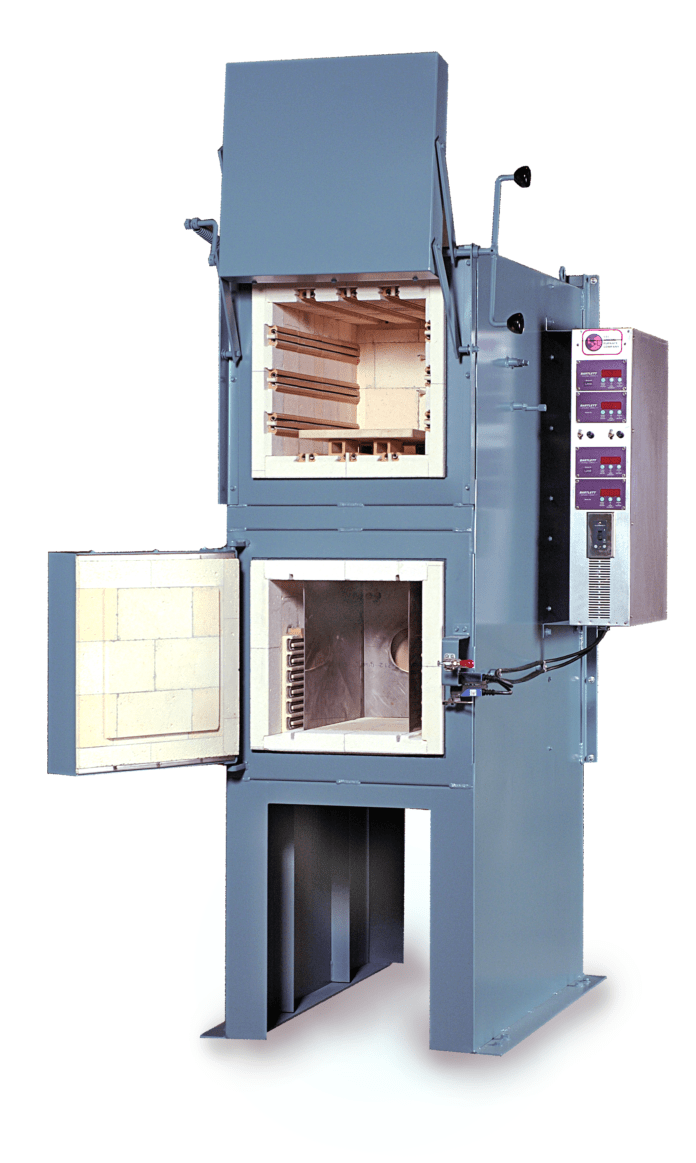

The top chamber is primarily deployed for heat-treating tool steels at temperatures up to 2,200°F; the tempering chamber is suited to temperatures up to 1,250°F and has a recirculation baffle that makes it suitable for small aluminum work as well. The hardening and tempering chambers have interior dimensions of 12” wide by 8” high by 24” deep, with total external dimensions of 55” wide by 70” tall by 56” deep.

The QDD29 is controlled with digital single setpoint controls along with overtemperature protection. Solid-state relays drive the heating elements in a simple, robust control circuit.

All L&L Special Furnace machines can be configured with various options and be specifically tailored to solve your thermal needs. We also offer furnaces equipped with pyrometry packages to meet the latest ASM2750 specifications.

Options include a variety of control and recorder configurations. An optional three-day, all-inclusive startup service is available with each system in the continental US and Canada. International startup and training service is available by factory quote.

If precise temperature control and uniformity is key to your process, then L&L’s QDD, QD and QDS series is a great choice.