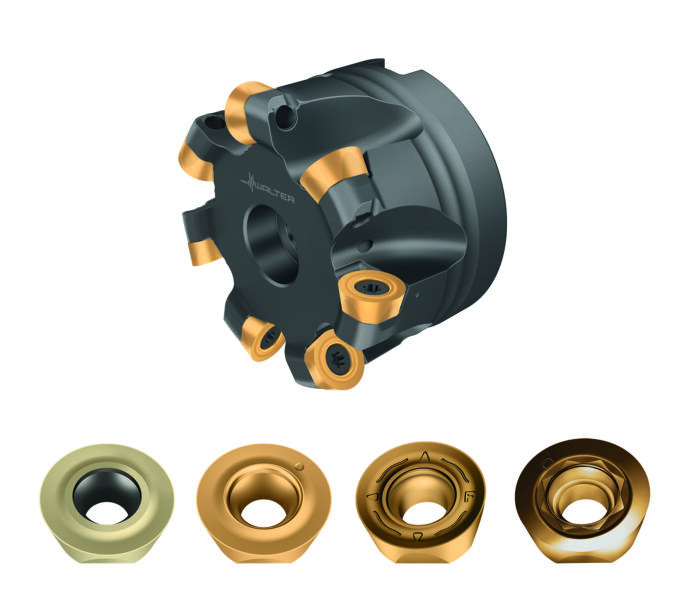

The F2334R milling cutter, in which the R stands for “reinforced,” is the first choice for blade machining. The cutter features a stable pocket design and a radial positive geometry to provide a soft cutting action. The cutters are available in diameter from 1¼” to 2½” and 25 to 80 mm. The usual DOC is 3 mm, with a 3.5 mm maximum, for the 10 mm insert and 4 mm, with a 4.5 mm maximum, for the 12 mm insert.

Because turbine blades are exposed to extreme thermal and physical loads, only difficult-to-cut materials such as high-temperature super alloys can withstand such forces. The WMP45G with an optimized combination of toughness and high-temperature wear resistance, as well as less sensitivity to cracking, provides high process reliability and is the benchmark for blade machining.

Several insert geometries are available. The geometry F67 is for “light. cutting” and is the first choice because of the low cutting forces being exerted. The strong D67 is mainly used for nickel-based super alloys due to its high cutting-edge stability. The universal D57 is for medium machining conditions and is suitable for applications other than blade machining.

About Walter

Walter, a global leader in the metalworking industry for over 100 years, offers a wide range of precision tools for milling, turning, drilling and threading applications. The company helps customers in the aviation and aerospace industries, automotive, energy, and general metalworking industry improve process reliability and increase productivity. As an innovative partner capable of creating digital process solutions for optimal efficiency, Walter is pioneering Industry 4.0 throughout the machining industry. With Regional Headquarters in Greer, SC, Walter markets its competence brands Walter, Walter Titex, Walter Prototyp and Walter Multiply through a network of channel partners and field engineers across the USA, Canada, Mexico and Brazil.