Leifeld Metal Spinning has completed a full acquisition of Boese Systems GmbH & Co. KG. This move allows the metal forming machine tool specialist to extend its expertise in areas such as the retrofit of PNC spinning machines. With this acquisition, Leifeld is one step closer to achieving its goal of offering customers complete comprehensive service.

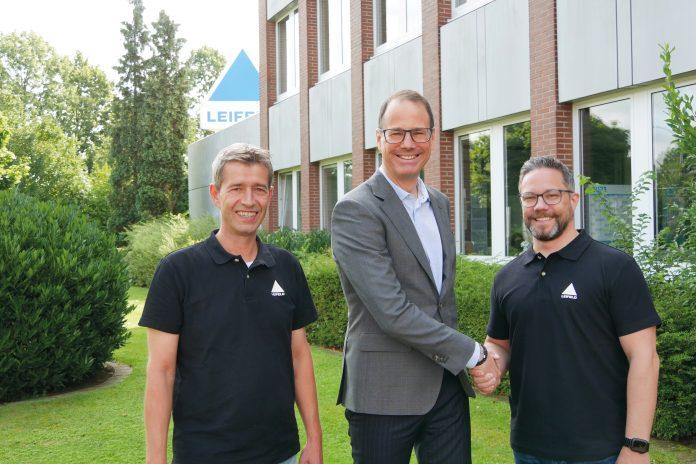

Leifeld’s machines for chipless metal forming are used worldwide in the automotive, aerospace, wind power and energy industries. As part of an asset deal, the company from Ahlen in Germany has now taken over Boese Systems, a supplier of PLC programming, drive technology and NC-controlled axes. With this acquisition, Leifeld benefits from the long-standing expertise and competence of Boese in the service and modernization of PNC spinning machines as well as control systems and their upgrades. “In addition to staff reinforcement in our service team, we are acquiring valuable expertise in the expansion of our services with the purchase of Boese Systems. Especially for older spinning machines with PNC controls, we now have a clear added value in customer support,” says Oliver Reimann, CEO of Leifeld. “With this, we’re reinforcing our service strategy that highlights customers as our focus.”

Before the former managing director Kevin Boese started his own family business, he worked for the Ahlen-based machine builder for almost eleven years. As a supporter of the new service orientation at Leifeld, Kevin will now add his talents and expertise to this division of the company as a technician. He will play a leading role in implementing and further developing the new strategy. Boese brings with him extensive expertise in control systems from the manufacturer Pauly. These are mainly installed in the older PNC machines.

“With my company, I have been a driving force in developing the controls together with Pauly over the past few years,” Boese reports. “Now, in order to retrofit older machines, we at Leifeld will optimise the programme storage as well as the online access.” The machine builder also benefits from his experience in being able to convert and expand the systems as easily as possible. Added to this is his expertise in electrical design to simplify commissioning.

New Orientation with Customer Focus

Leifeld offers a worldwide range of services. This enables customers to reduce their operating costs, maintain the availability of the machines and increase their safety throughout the entire machine life cycle. The offer includes inspections, maintenance contracts, repairs, spare parts supply, modernisations, trainings as well as the purchase and sale of used machines.

Leifeld service manager Stephan Stamm: “With the new orientation we want to intensify customer proximity. Four service technicians are now a permanent part of our field service team. On the so-called road show, they visit and advise our customers on site.”

With the newly gained expertise, Leifeld can tackle the retrofit and used machine business more intensively. “After the general overhaul of the machines at our company with original parts or, if necessary, new designs, they are again in as-new condition,” promises Stephan Stamm. “Our customers define with us the scope of services that makes the most sense for them. We provide comprehensive services, just as we do for new machines – from commissioning to component development. The availability of spare parts, especially in the area of the control system, is again guaranteed.” When selling a used Leifeld machine, the service team is the right contact for all questions. In addition, the spare parts market is expanded: Leifeld increases its minimum stock of selected components to improve the availability of spare parts.