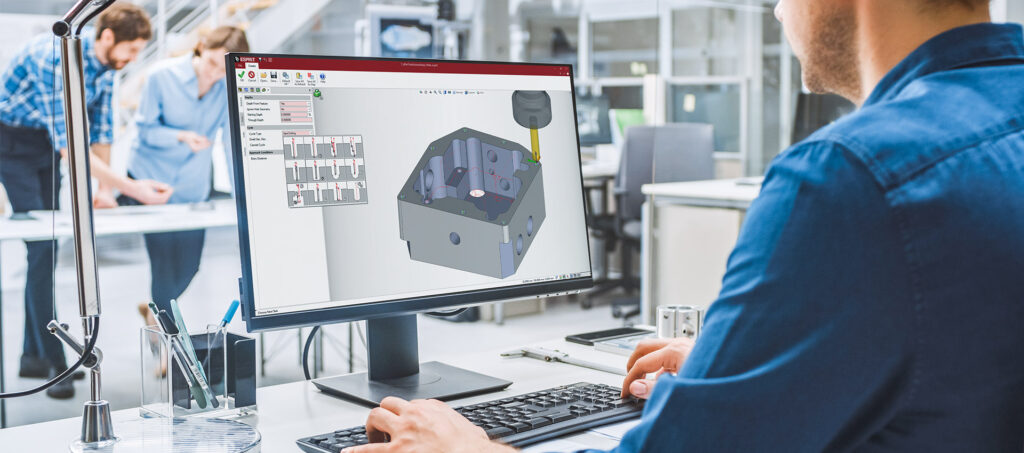

Traditionally, ESPRIT’s applications engineers lead in-person trainings in ESPRIT offices and also on-site at customer facilities around the world. While application engineers offer some of the best CAM courses in the industry, their team understands that not everyone who needs software training has the resources to travel to an ESPRIT office.

Traditionally, ESPRIT’s applications engineers lead in-person trainings in ESPRIT offices and also on-site at customer facilities around the world. While application engineers offer some of the best CAM courses in the industry, their team understands that not everyone who needs software training has the resources to travel to an ESPRIT office.

To support customers throughout the pandemic, ESPRIT began conducting instructor-led, online training sessions in early 2020. The response has been overwhelmingly positive. To further satisfy users’ growing appetite for high-quality online training, they now introduce their Learning Center to the general public.

The ESPRIT Learning Center is an online training platform with on-demand, self-paced training courses created specifically for ESPRIT CAM programmers. ESPRIT’s top engineers and instructors have poured a huge amount of effort and energy into creating these courses. The first learning paths to be released are “New User Milling,” “New User Turning,” and “New User Mill-Turn.” Each learning path includes five to seven training courses that guide users through several different machine models and part models to introduce different machining processes in ESPRIT.

The main purpose for creating discrete online learning paths is to replicate what a student can learn from an on-site training class. Users may take the course anywhere, and at any time. ESPRIT customers can learn at their own pace while saving the time and cost associated with traveling. Each learning path also comes with one ESPRIT student license for each learner, so users can take the courses at home or in their free time, without interrupting their daily programming or production work.

“ESPRIT Learning Center gives us the exact learning experience that we’ve been looking for. The courses are very thorough, wasting no time getting to the point. Having all the supplied files and models within the course window makes access quick and convenient.” said Scott Hornbeak, programmer at Cassavant Machining. “This online training will not only make it easier for existing ESPRIT users to transition to the new ESPRIT—it will also help our new programmers rapidly get familiar with ESPRIT, without the need to travel to a training site.”

“ESPRIT Learning Center is a game-changer for our customers who want to learn ESPRIT,” says Yijun Fan, director of product marketing at DP Technology, the makers of ESPRIT. “Our end goal is to make high-quality ESPRIT training courses more accessible to our global customers. We want to share our best practices with users so they can optimize their machine programming to reduce the cycle time, machine setup time, and machine downtime. We want our users’ machines to start running as soon as possible and keep running at the highest efficiency. And that’s always going to be our priority at DP Technology.”

About ESPRIT and DP Technology Corp.

DP Technology Corp. is a leading developer and supplier of computer-aided manufacturing (CAM) software. ESPRIT®, DP Technology’s flagship product, is a powerful CAM system for CNC programming, optimization, and simulation—supporting the entire manufacturing process. With factory-certified post processors delivering machine-optimized G-code and ESPRIT’s ability to solve unique challenges with automation solutions, ESPRIT is the smart manufacturing solution for any machining application. With world-class technical support, ESPRIT empowers you to get started quickly and keep running at top efficiency. DP Technology reinforces its commitment to technical excellence by dedicating nearly 20 percent of its annual revenue to ongoing research and product development. This long-term focus has produced powerful technological innovations that have placed ESPRIT in an industry-leading position since its market launch in 1985.

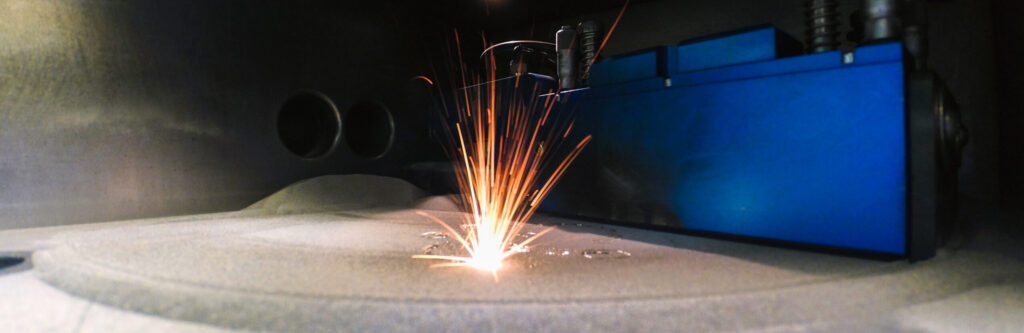

ESPRIT CAM Collaborates with Alma CAM for Robot Additive DED Programming

Additive DED (direct energy deposition) is a series of metal 3D printing technologies that creates parts by melting and fusing material as it is deposited. Wire arc additive manufacturing (WAAM), also known as DED-arc, is one of the additive DED technologies being applied in robot additive DED to produce the near net shape preforms with significant cost and lead time reductions, increased material efficiency, and improved component performance.

Compared to a machine tool-based DED machine, which can cost up to several million dollars, a robotic DED machine costs significantly less (close to $150,000 to $200,000 USD). Additionally, many companies have existing programmable, industrial robots that can be retrofitted for additive DED applications. To provide customers with an end-to-end solution for programming robot additive DED, ESPRIT has been working with Alma to bring the best of the two worlds together—the world’s most advanced toolpath planning in both subtractive and additive areas, and the industry-leading technology in robotics trajectory computation and off-line programming of arc welding robots.

This solution allows Alma to use the full ESPRIT additive DED cycles such as 3x, 4x, and 5x, bringing the software to a new level of support for additive technology. On the other hand, the solution allows ESPRIT to support industrial robot brands including Yaskawa, ABB, Fanuc, Kuka, and many others.

The result of this technology partnership is a complete workflow to provide end-users with:

- Dedicated additive toolpath planning and programming

- Robot programming, simulation, verification, collision detection, and code generation

- Subtractive finishing process planning, simulation, verification, collision detection, and G-code generation