Toyota Racing Development (TRD), U.S.A. named GF Machining Solutions, a world leading provider of machine tools, automation solutions and services to manufacturers of precision components, as an Official Technical Partner. After adding GF’s high- performance manufacturing and automation technology, TRD has accelerated production of key aluminum and cast-iron components for their 800-horsepower racing car engines — including the engines used in the #78 Furniture Row Racing Toyota Camry of Monster Energy NASCAR Cup Series driver and 2017 series champion Martin Truex Jr.

Toyota Racing Development (TRD), U.S.A. named GF Machining Solutions, a world leading provider of machine tools, automation solutions and services to manufacturers of precision components, as an Official Technical Partner. After adding GF’s high- performance manufacturing and automation technology, TRD has accelerated production of key aluminum and cast-iron components for their 800-horsepower racing car engines — including the engines used in the #78 Furniture Row Racing Toyota Camry of Monster Energy NASCAR Cup Series driver and 2017 series champion Martin Truex Jr.

Approximately 200 TRD employees in Costa Mesa, California design and build race engines for NASCAR teams that field Toyota Camrys in the Monster Energy NASCAR Cup series. To keep pace with a grueling 38 race annual schedule, strict series regulations, and a highly-competitive racing environment, TRD designs, develops, manufactures and builds more than 300 engines in-house, annually. Precision, quality and speed of manufacture are the pillars of performance for TRD’s manufacturing operation.

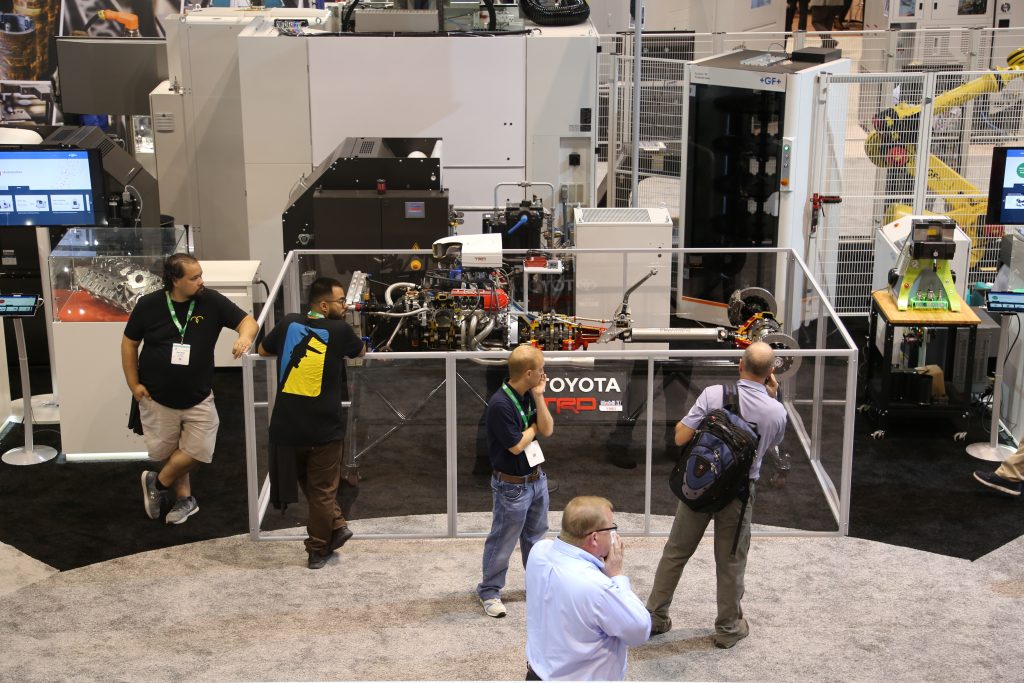

TRD began their initial relationship with GF Machining Solutions in 2014 when they added a fully-automated production cell to their manufacturing facility. Comprised of seven 5-axis machining centers (six MIKRON HPM 800 U HD machines and one MIKRON HPM 1350 U) connected to a shared pallet pool system, the system uses a rail-guided robot to load the machines from more than 80 open pallets along a 32-meter track.

Machining an individual part at TRD can take only a few minutes or in some cases up to 15 hours; with part sizes ranging between 1″ and nearly 20″ in a single dimension, and tolerances at or below 5µm. Complex contoured surfaces require full simultaneous 5-axis production, which also provides better accessibility and fixturing for other parts. By using the automated cell, TRD is able to reduce component lead times, boost machining capacity and achieve a 22-percent increase in productivity.

“GF Machining Solutions is honored to be an Official Technology Partner for Toyota Racing Development,” says Scott Fosdick, President GF Machining Solutions North America. “We look forward to developing alongside TRD to improve processes and efficiencies for both companies while advancing newer technologies for the future of manufacturing and racing.”

“TRD is very excited to see how this relationship will push the boundaries of our on track performance,” says Greg Ozmai, Group Vice President of Operations at TRD. “The results of our collaboration with GF Machining Solutions were immediate and have exceeded our expectations. The Mikron cell’s flexibility allows TRD to put over 100 different parts through the cell and the added precision has improved the overall engine performance, which propelled TRD to the winner’s circle in 2017.”

Launching the Mikron MILL P 500 U

GF Machining Solutions’ Mikron MILL P 500 U high-performance milling solution made its North American debut at IMTS with its powerful and dynamic material removal capabilities and high stiffness, this solution takes precision and surface finish to a new level.

The Mikron MILL P 500 U enables continuous machining of complex forms and tough materials while shortening process time. Its advanced thermal stability ensures reliable precision over long machining periods. Furthermore, it delivers exceptional competitiveness by integrating smart automation and ensures the process reliability essential to precision parts manufacturing segments such as aerospace and machinery parts as well as automotive mold making.

Dynamic Machining And Flexibility, 365 Days Per Year

Thanks to the Mikron MILL P 500 U’s 1.7 g acceleration, 36 kW Step-Tec Spindle, rotary tilting table capacity of up to 600 kg and workpiece diameters up to 707 mm, manufacturers experience constant dynamic machining as well as 100 percent flexibility in their part production.

The rotary tilting table is available in several variations: T-slot tables accommodating a payload of 200 kg, 400 kg or 600 kg, as well as pallet tables accommodating a payload of 200 kg, 400 kg or 600 kg. Incremental, direct angle measuring systems are mounted on the swiveling and circular axes to guarantee very high positioning and repeat accuracy. Both axes are driven via water-cooled torque motors: one for T-slot tables, two for pallet tables on the A-axis and one on the C-axis. These direct drives bear optimal characteristics for precise, simultaneous operations. For heavy-duty machining, the rotary and swivel axes can be clamped and—for best machining stability—the swiveling axis has clamping on both side supports.

The rotary tilting table is available in several variations: T-slot tables accommodating a payload of 200 kg, 400 kg or 600 kg, as well as pallet tables accommodating a payload of 200 kg, 400 kg or 600 kg. Incremental, direct angle measuring systems are mounted on the swiveling and circular axes to guarantee very high positioning and repeat accuracy. Both axes are driven via water-cooled torque motors: one for T-slot tables, two for pallet tables on the A-axis and one on the C-axis. These direct drives bear optimal characteristics for precise, simultaneous operations. For heavy-duty machining, the rotary and swivel axes can be clamped and—for best machining stability—the swiveling axis has clamping on both side supports.

With the 20,000 rpm Step-Tec HPC190 Spindle with HSK-A63 tool interface, manufacturers extend their flexibility and benefit from the best universal spindle selection for stiffness, power, speed, and safety with Machine and Spindle Protection (MSP). Also available is Step-Tec’s 36,000 rpm HVC150 motor spindle with HSK-E50 tool interface; this spindle solution is particularly advantageous for mold makers working with small cutting tools and dynamic 1.7 g acceleration to efficiently achieve best surface finishes.

250 Percent Higher Productivity

At the same time, precision parts producers and mold makers can more than double productivity with the 11-square-meter Mikron MILL P 500 U’s accommodation of limitless integrable automation solutions through the back. That means users can achieve reliable, efficient unmanned third-shift productivity due to an array of automation choices as well as direct System 3R robot loading of pallets to the table and the availability of parts handling solutions. For example, manufacturers’ productivity and agility are increased with System 3R’s JobToolManagement (JTM) user-friendly software for one machine with an integrated pallet changer. With JTM, the user assigns numerical control (NC) programs to pallet positions by dragging and dropping on a touch screen.

Only 10 Minutes To Resume Full Production After A Crash

Mikron MILL P 500 U users slash their downtime from hours to mere minutes, thanks to GF Machining Solutions’ Industry 4.0 supporting smart modules such as Machine Spindle Protection (MSP) and Customer Services’ rConnect modular digital services including Live Remote Assistance (LRA).

MSP protects the spindle and machine geometry while maximizing machine uptime to reduce costs associated with unexpected spindle collisions. Collisions usually occur when a new CNC program is first executed. MSP protects the machine and spindle during job setup by making it possible to absorb axial and lateral collisions and then restore perfect accuracy. The spindle can return to normal operations without any specific maintenance or recalibration, ensuring almost no downtime or collision-related costs.

Users’ productivity, flexibility and autonomy are further accelerated by the Mikron MILL P 500 U’s rConnect readiness. Manufacturers simply choose the GF Machining Solutions digital services that best fit their needs. LRA, for example, delivers highly secure, direct, customer-authorized real-time remote assistance by connecting the customer with the local diagnostics center and GF Machining Solutions’ Technical Units. With LRA, Customer Services can inspect a machine tool remotely, with diagnostics carried out by the customer’s own technician or a GF Machining Solutions expert.

Mikron MILL P 900 Offers High Precision, Stability

GF Machining Solutions also debuted the Mikron MILL P 900 3-axis vertical milling machine at IMTS. The highly precise and productive machine is especially beneficial to mold and die manufacturers.

GF Machining Solutions also debuted the Mikron MILL P 900 3-axis vertical milling machine at IMTS. The highly precise and productive machine is especially beneficial to mold and die manufacturers.

The Mikron MILL P 900 features a polymer concrete machine base that delivers extreme dynamic stiffness, while its thermal management, contour accuracy and precise positioning contribute to superior part surface finishes. A symmetrical portal design and effective chip management heighten operational efficiency.

The machine uses the fast and efficient FANUC FS31iB CNC. Within the control are multiple machine optimization modules and smart machine features that effectively increase productivity and reduce energy consumption.

To further reduce cycle times, the machine packs an aggressive high-speed 20,000-rpm StepTec spindle that delivers 120 N·m of torque. The spindle features an advanced 3D acceleration sensor (V3D) vibration monitoring system that uses three vibration sensors to provide a complete and accurate visualization of spindle performance. An optional 36,000-rpm spindle delivers superb surface finishes thanks to its axial stability, making it perfect for the production of high-end molds with tight finish and size tolerances.

The Mikron MILL P 900 comes standard with a 30-position tool magazine and automatic tool changer; a 60-position tool magazine is also available. With easy access via a side door on the machine, operators can change out tools with ease. The tool changers also deliver a fast 4.2-second change time and a 7.4- second chip-to-chip change time.

About GF Machining Solutions

GF Machining Solutions is the world’s leading provider of machines, diverse technical solutions and services not only to the tool and mold making industry but also to manufacturers of precision components. The portfolio ranges from electrical discharge machines, high-speed and high-performance Milling machines—including clamping and palletization systems, 3D Laser surface texturing machines and Spindles—to solutions for Tooling and Automation, services, spare parts, expendable parts, consumables and Digitalization solutions. GF Machining Solutions is a globally acting Division of the Georg Fischer Group (Switzerland) and maintains a presence on 50 sites worldwide within its own organization. Its 3,255 employees generated sales of CHF 992 million in 2017.