Online sales show no sign of slowing and the growth is driving demand for fulfillment operations to pack and ship all those ordered goods. The work is repetitive, however, and requires high accuracy to reduce costly errors or returns. That means that jobs in picking and packaging items for shipping aren’t particularly desirable, especially in tight labor markets. These tasks are ideal for automation, but there are challenges. While repetitive, packaging applications are also highly variable, requiring the ability to recognize and pick a wide range of items, in different sizes, weights, and materials. And human workers are typically still needed for upstream and downstream processes that are often performed right next to the packaging operation.

Online sales show no sign of slowing and the growth is driving demand for fulfillment operations to pack and ship all those ordered goods. The work is repetitive, however, and requires high accuracy to reduce costly errors or returns. That means that jobs in picking and packaging items for shipping aren’t particularly desirable, especially in tight labor markets. These tasks are ideal for automation, but there are challenges. While repetitive, packaging applications are also highly variable, requiring the ability to recognize and pick a wide range of items, in different sizes, weights, and materials. And human workers are typically still needed for upstream and downstream processes that are often performed right next to the packaging operation.

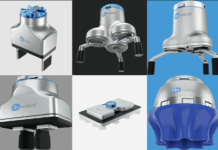

With that combination, collaborative robots fit the bill perfectly.

Cobots offer low upfront costs, flexible implementation, and easy programming for developers who are rapidly creating innovative new systems to optimize bin-picking and packaging. And with no need for safety guarding (after risk assessment), they are ideal for collaborative operations next to human workers.