Industrial air curtain applications aren’t new, but plant engineers are finding a host of new uses for the decades-old product. Air curtains became staples for dock and ground-level door energy savings during the second half of the 20th Century, especially after the 1970’s oil embargos and ensuing energy price rise. Since then, industrial manufacturers spanning every possible category opted to outfit door openings with air curtains to save energy. In facilities for aerospace, automotive, off-highway and other manufacturing categories where doorways range up to 16-feet-wide or 30-feet-high, energy savings is critical for plant operation budgets. Recently, plant managers are also opting for uniform temperatures for both employee comfort and product quality assurance.

Industrial air curtain applications aren’t new, but plant engineers are finding a host of new uses for the decades-old product. Air curtains became staples for dock and ground-level door energy savings during the second half of the 20th Century, especially after the 1970’s oil embargos and ensuing energy price rise. Since then, industrial manufacturers spanning every possible category opted to outfit door openings with air curtains to save energy. In facilities for aerospace, automotive, off-highway and other manufacturing categories where doorways range up to 16-feet-wide or 30-feet-high, energy savings is critical for plant operation budgets. Recently, plant managers are also opting for uniform temperatures for both employee comfort and product quality assurance.

Industrial employee comfort has become increasing important especially in northern regions where cold open doorway drafts affect employee health and productivity and potentially lead to union grievances. Product quality assurance can be improved and parts production shrinkage can be decreased by providing minimal temperature variances near sensitive areas, such as computer numerical control (CNC) processes. Air temperatures near open doorways in winter can fluctuate temperatures tens of degrees and consequently skew critical tolerances required for precision cutting, stamping, punching and other CNC processes.

One example is a Miamisburg, Ohio-based metal preparation and fabrication supplier that was challenged by interior temperature fluctuations affecting sensitive production equipment near a shipping door. Industrial equipment dealer McCormick Equipment Co., Inc., Cincinnati, solved temperature fluctuations and significantly reduced production discards with an air curtain. McCormick installed a 12-foot long horizontal mount air curtain over the client’s 12 (w) x 14 (h)-foot shipping door, which is open four hours/day, five days/week. Although quality assurance was the motivation, an energy audit was still performed to show the added benefits of an air curtain. Payback from energy savings alone was 1.01 years, based on 32 weeks of wintertime operation.

Air curtain technology draws interior air from the facility and discharges it through field-adjustable (+/- 20-degree) linear nozzles that “seal” the doorway with a non-turbulent air stream meeting the floor approximately at the door opening threshold. A properly-sized air curtain can contain approximately 70 to 80-percent of that air and return it to the space. An air curtain separates the indoor/outdoor environments and effectively prevents outside air, dust and flying insect infiltration by discharging air ranging from 1,000 to 7,000 ft/min. velocities, depending on the door height and mounting height. The air curtains are typically activated by a limit switch or a smart control that can be programmed for a variety of opening and closing functions, as well as supplemental spot heating from optional on-board electric, gas-fired, steam or hot water coils. Air curtains can also draw wasted heat stratified at the ceiling via sheet metal fabricated plenums and distribute it back into the occupied zone. Smart controls can delay de-activation after the door closes and run air curtain heating until area temperatures are thermostatically satisfied.

Air curtain technology draws interior air from the facility and discharges it through field-adjustable (+/- 20-degree) linear nozzles that “seal” the doorway with a non-turbulent air stream meeting the floor approximately at the door opening threshold. A properly-sized air curtain can contain approximately 70 to 80-percent of that air and return it to the space. An air curtain separates the indoor/outdoor environments and effectively prevents outside air, dust and flying insect infiltration by discharging air ranging from 1,000 to 7,000 ft/min. velocities, depending on the door height and mounting height. The air curtains are typically activated by a limit switch or a smart control that can be programmed for a variety of opening and closing functions, as well as supplemental spot heating from optional on-board electric, gas-fired, steam or hot water coils. Air curtains can also draw wasted heat stratified at the ceiling via sheet metal fabricated plenums and distribute it back into the occupied zone. Smart controls can delay de-activation after the door closes and run air curtain heating until area temperatures are thermostatically satisfied.

One recent innovation has made electric heating more efficient. Previously air curtain manufacturers put electric heating coils in the airstream, which inefficiently interrupted the air stream. Now, manufacturers are mounting electric elements at both air inlets of the blower housing to maintain an uninterrupted, laminar airflow from the blower to the air discharge nozzles for a more efficient doorway opening seal.

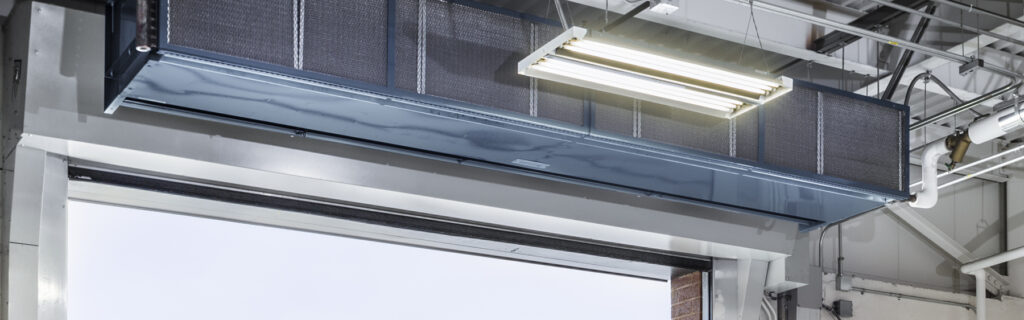

New Single Length Construction

Another recent innovation from manufacturers is single length construction. Previously, the industry only offered shorter lengths that needed bolting together to cover doorway widths greater than 12 feet. Now single lengths are available in single lengths up to 16-feet with single custom lengths up to 24 feet. Single lengths don’t create airstream disrupting obstructions as do models with multiple smaller lengths at their connection points. Additional mounting hardware can raise project costs, because each length must be supported independently to prevent sagging even though they’re bolted together. Because single length construction uses heavier gauge, welded steel and internal beam construction, they need only ceiling-mounted threaded rods at the four corners.

Unusual Applications

Sometimes end-users conceive of unconventional uses for air curtains, such as Coleman Tool and Mfg. Co., a welding, machining and metal fabrication manufacturing company specializing in replacement parts for waste disposal vehicles. Coleman installed air curtains for two 16 x 16-foot and one 12 x 12-foot overhead doors at its 60,000-square-foot Union Grove, Wis., headquarters. The three units help maintain a 60°F plant wintertime temperature, which is generated purely from its welding process production waste heat.

Using air curtains for energy savings is common; however Coleman had its air curtains modified to also filter airborne welding smoke and contaminants. About 20 percent of smoke evades the floor-level industrial air filtering walls positioned around the welding areas. The smoke results in a stratified blue haze above the plant floor. Consequently, Coleman’s maintenance department fabricated 24 x 24-inch steel filter racks that fit onto the air curtains’ air intakes. The racks are designed to use replaceable, off-the-shelf MERV-8 (minimum efficiency reporting value) pleated filters. MERV 8 doesn’t affect airflow performance and the hinged doors help expedite filter replacement in less than 10 minutes.

Using air curtains for energy savings is common; however Coleman had its air curtains modified to also filter airborne welding smoke and contaminants. About 20 percent of smoke evades the floor-level industrial air filtering walls positioned around the welding areas. The smoke results in a stratified blue haze above the plant floor. Consequently, Coleman’s maintenance department fabricated 24 x 24-inch steel filter racks that fit onto the air curtains’ air intakes. The racks are designed to use replaceable, off-the-shelf MERV-8 (minimum efficiency reporting value) pleated filters. MERV 8 doesn’t affect airflow performance and the hinged doors help expedite filter replacement in less than 10 minutes.

The IAQ results have been significant. The haze is gone, the production floor’s air smells fresh, and the plant’s chronic asthma sufferers notice significant breathing improvements, according to plant executives. One important factor in Coleman’s air filtering success is the fact its building operates with a positive pressure. Some welding shops run under a negative pressure, which will adversely affect air curtain performance.

Another recent innovation is hazardous location (HL) air curtains. Industrial buildings can be designated hazardous locations, because ignitable substances are prevalent, such as explosive powders, grains, chemicals or gasses, especially compressed natural gas (CNG). HL air curtains feature explosion-proof motors, spark-resistant fans, HL electrical components and construction, and other precautions required by ANSI/NFPA-70 National Electrical Code (NEC) regulations. Standard construction must comply with Class I, Division 1 and 2, Groups C and D for gases; and Class II, Division 1 and 2, Groups F and G for dust.

Getting Air Curtain Purported Performance

When an air curtain manufacturer’s specification claims and the product’s actual performance statistics vary, the protection of a doorway has substandard efficacy. For example, an engineer might specify a particular discharge cfm, but an overstated specification in a manufacturer’s catalog might result in poor performance and ultimately lost energy saving potential. Volume, velocity and uniformity of the air stream are critical factors in an air curtain’s effectiveness; therefore it’s important that air curtains perform up to manufacturers’ specifications. The Air Movement & Control Association (AMCA-International), Arlington Heights, Ill., which is a not-for-profit organization that tests and certifies fans, blowers, air curtains and other air movement devices, created a test standard to assess air curtains and certify their performances. To assure an air curtain meets minimum standards, it should bear the seal of AMCA Standard 220, “Laboratory Methods of Testing Air Curtain Units for Aerodynamic Performance Rating.” This is now a test that’s an American National Standards Institute (ANSI) standard.

Air curtain operation and applications have come a long way since they entered the North American industrial scene more than 50 years ago. They’re now staples of industrial energy savings, employee comfort and quality assurance.