Sandvik Coromant, is upgrading its range of tools for steel tapping operations with two updates to its solid round tools range. The next generation CoroTap® T200 spiral point tap and T300 spiral flute tap for ISO P deliver improved process security, longer tool life and a reduced cost per component.

Sandvik Coromant, is upgrading its range of tools for steel tapping operations with two updates to its solid round tools range. The next generation CoroTap® T200 spiral point tap and T300 spiral flute tap for ISO P deliver improved process security, longer tool life and a reduced cost per component.

Part of Sandvik Coromant’s solid round tools offering, the CoroTap range delivers material-specific solutions for threading a variety of metals. In particular, the CoroTap T200 and T300 are optimized for ISO P1 and P2 steel workpiece materials, making them suitable for machining components in the automotive and general engineering industries. This includes crank shafts, steering knuckles, and general engineering components such as housings and flanges. Both tools are suitable for mass production.

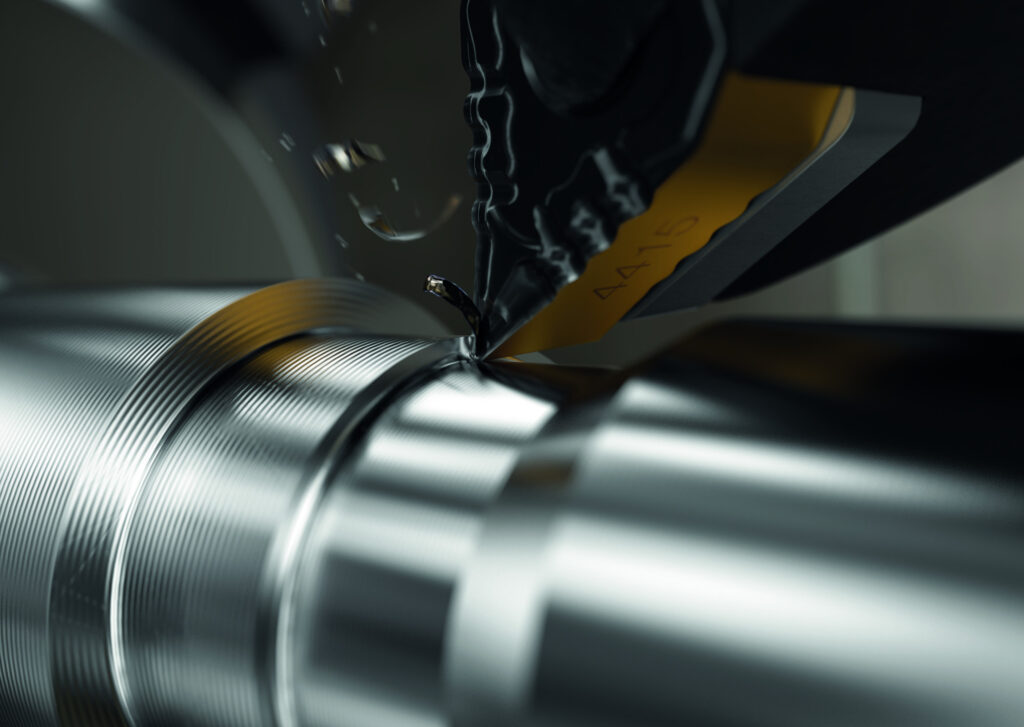

The CoroTap T200 has a spiral point, while the T300 is a spiral flute tap. While the spiral point of the T200 is suited for machining through holes, where chips are pushed forwards, the T300 is catered to blind holes, where there is no exit hole and chips must be pulled backwards. As part of the upgrade, both tools have a new surface treatment, as well as improved edge rounding for better finishing inside the machined hole. An improved flute form also offers better overall performance.

As a result of these upgrades, manufacturers will benefit from improved process security with increased resistance to edge chipping, leading to fewer tool breakages and an improved quality of the machined thread. In addition, cutting speeds are higher than previous versions of the tool and there is an overall reduction in the cost per part.

Another major difference compared to previous versions of the CoroTap range is the improved CoroTap T200 and T300 can benefit from Sandvik Coromant’s Tailor Made web assortment. Serving the industry with tailored manufacturing tools, the Tailor-Made service gives customers the freedom to specify their own dimensions, without paying for a specialist tool. The taps can be adjusted to meet the demands of multiple industries and are adaptable to specific requirements.

“Performance case data demonstrates significant improvement for the tools,” explains Lisa Belfrage, Global Product Manager at Sandvik Coromant. “In fact, a comparison of the new and existing T200 tap demonstrates a 121 percent increase in tool life, with the potential to machine over double the number of threaded holes using a single tool. Productivity is also increased with the upgraded T200 — with cutting speeds increasing from 18 metres per minute (m/min) to 24 m/min with machining P2 steel.

“The new generation of the T300 has seen a significant increase in tool life compared to the previous version,” added Belfrage. “What’s more, when compared to a competing tool on the market, Sandvik Coromant’s upgraded CoroTap T300 demonstrates a 57 percent increase in tool life and higher cutting speeds.

“With demonstrated process improvements, and the ability to offer tool customisation with the Tailor Made service, the new generations of the CoroTap tools will make thread cutting faster and more efficient for our customers”.

Enhance Steel Turning Productivity

Enhance Steel Turning Productivity

With New Carbide Grades Following the launch of two new carbide turning grades in October 2020, Sandvik Coromant has extended its steel turning product line with additional assortments. The insert grades, GC4415 and GC4425, are designed for external and internal machining of low-alloyed and unalloyed steels. The extension of the range provides productivity improvements.

Sandvik Coromant’s GC4415 and GC4425 steel turning grades are ideal for manufacturers operating in mass and batch production set-ups. GC4425 is a machinist’s first choice for steel turning, outperforming competition in a majority of steel turning applications. The new grade provides improved wear resistance, heat resistance and toughness, considerably expanding the application range. Grade GC4415 complements GC4425 when more heat resistance is needed.

To increase their use for steel turning applications across the automotive, energy and general engineering sectors, the upgrade includes more insert shapes for each grade. Having access to the correct insert shape is vital for effective finishing and roughing operations, and the insert shape should be selected relative to the entering angle accessibility required of the tool.

“In October 2020, Sandvik Coromant made a total of 547 items available as part of the grades’ release,” explained Rolf Olofsson, Product Manager at Sandvik Coromant. “However, to meet the demands of Sandvik Coromant’s wide-ranging customer base, we always aim to build on our product innovations and continuously improve. As a result, an additional 381 items have been added to the range.

“The GC4415 and GC4425 inserts show superior wear resistance over competing inserts, which contributes towards extended tool life and predictable performance with every use. This also minimizes material waste, both from the workpiece and the insert. With these benefits in mind, offering extra insert shapes that are compatible with more tool holders means that more customers will be able the take advantage of GC4415 and GC4425 for their steel turning operations.”

While still relatively new to the market, GC4415 and GC4425 have demonstrated measurable productivity benefits since their first release. One general engineering customer, using the GC4415 insert to carry out roughing on a P2.5.Z.HT steel workpiece to machine a pulling rail, saw a 80 percent productivity increase and a 100% increase in tool life when compared to a competing grade.

Elsewhere, when roughing an axis for a power generation customer, the GC4425 demonstrated a 90 percent increase in tool life, providing secure machining with stable and predictable flank wear and no notch wear.

“Despite launching at the end of 2020, GC4415 and GC4425 have already delivered huge productivity and cost-saving benefits for our customers,” said Olofsson. “Every manufacturer wants to achieve increased metal removal rates, more pieces per edge, reduced cycle times, minimised waste and optimized inventory use. For the GC4415 and GC4425, the proof is in the numbers.

“Now, with the latest upgrades to the insert range, Sandvik Coromant will be able to help even more customers enjoy the benefits of optimized, efficient steel turning.”

About Sandvik Coromant

Part of global industrial engineering group Sandvik, Sandvik Coromant is at the forefront of manufacturing tools, machining solutions and knowledge that drive industry standards and innovations demanded by the metalworking industry now and into the next industrial era. Educational support, extensive R&D investment and strong customer partnerships ensure the development of machining technologies that change, lead and drive the future of manufacturing. Sandvik Coromant owns over 3100 patents worldwide, employs over 7,900 staff, and is represented in 150 countries.