Headquartered in Wapakoneta, Ohio, FlexCNC and FlexArm have been manufacturing CNC machines as well as tapping arms, die grinding arms, torque arms, assembly and part manipulators, and more, since 1984. The company has globally expanded its sales, with more than 600 customers worldwide, and now operates out of a new 50,000 square foot facility.

The latest addition to their lineup of machining centers for large or long parts – like structural steel beam – in a single set-up is the FlexBEAM line. With an open bed design that measures 40-feet by two-feet, this new model can machine parts up to 40 feet in length. Alternately, the long open bed, coupled with the movable safety light curtain, allows multiple set-ups, so that while the FlexBEAM is machining one part, another can be loaded, or offloaded. This dramatically increases the productivity of the machine’s uptime. The open design provides unrestricted access which makes loading and unloading easier and faster. In addition to structural steel beams, FlexBEAM machines are ideal for the machining of long products like tube, or pipe, cutting keyways, and more.

The FlexBEAM has a monoblock welded steel frame with high rigidity and a t-slot machine bed. It features 3-axis interpolation, scribing, automatic hydraulic workholding and automatic tool touch-off. In addition, a laser zero detector is standard, as is 6 x ATC, a hand pendant, and network with ethernet cable.

Control on the FlexBEAM is simple yet powerful, with conversational and ISO G&M-code programming for versatile 3-axis CNC machining along with an optional 4th axis. Equipped with a color touch screen control, 40 GB of program storage, and 50 programmable zero points. Programs can be loaded through USB or through and ethernet connection. Extensive training is provided, both in-plant and on-site.

C-Series Vertical Machining Centers

C-Series Vertical Machining Centers

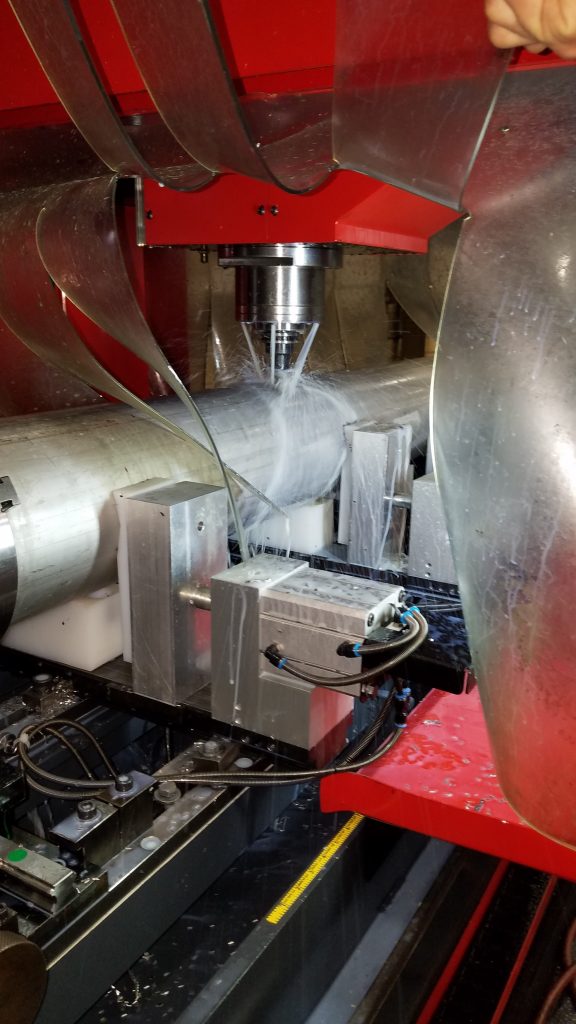

FlexCNC’s C-Series vertical machining centers drill, mill, tap and bevel large or long parts in a single set-up. With a 2-foot bed width and lengths from 10 to 80 feet, the C-Series is ideal for machining of long products like tube, or pipe, cutting keyways, and more. The C-Series features a monoblock welded steel frame with high rigidity and a t-slot machine bed. Spindle taper of CT or BT 40 are available, at 6000 RPM, with a max torque capability of 184 ft/lbs.

Standard unit runs on 480V and includes mobile light-curtain safety barriers, frame with chip conveyor and t-slotted table, flood coolant pump and tank, and automatic tool calibrator. The 12” color touch screen is water-resistant and durable enough to provide years of service. Oversized double hung precision linear guideways ensure smooth and precise movement on all axes. All moving parts are self-lubricating on all axes. A programmable servo motor drives the spindle, while a 10-compartment automatic tool change ensures capacity for virtually any application.

The C-Series is available in bed sizes from 10 feet to 80 feet, with custom length beds available to suit specific requirements.

G-Series Standard Edition Vertical Machining Centers

FlexCNC’s G-Series vertical machining centers for face milling, helical milling, rough milling, drilling and more, of large or long parts in a single set-up. The Standard Edition model 20-06 SE boasts a 20-foot by six-foot bed, to machine parts up to 20-feet in length. Alternately, the long open bed, coupled with the movable safety light curtain, allows multiple set-ups, so that while the 20-06 SE is machining one part, another can be loaded (or offloaded).

The 20-06 SE features a monoblock welded steel frame with high rigidity and a t-slot machine bed. Spindle taper of CT 40, at 6,000 RPM, with a max torque capability of 74 ft/lbs. (with 18 HP upgrade). This proven product line features maximum travel rate of 1200 in/min along the x axis, 1000 in/min along the y axis and 165 in/min along the z axis. Z-Axis travel is 19” max. Spindle nose to table distance from 5.5” to 25.0”.

The 20-06 SE features a monoblock welded steel frame with high rigidity and a t-slot machine bed. Spindle taper of CT 40, at 6,000 RPM, with a max torque capability of 74 ft/lbs. (with 18 HP upgrade). This proven product line features maximum travel rate of 1200 in/min along the x axis, 1000 in/min along the y axis and 165 in/min along the z axis. Z-Axis travel is 19” max. Spindle nose to table distance from 5.5” to 25.0”.

Standard unit runs on 480V and includes mobile light-curtain safety barriers, frame with chip conveyor and t-slotted table, flood coolant pump and tank, and automatic tool calibrator. The 12” color touch screen is water-resistant and durable. Oversized double hung precision linear guideways ensure smooth and precise movement on all axes. All moving parts are self-lubricating on all axes. A programmable servo motor drives the spindle, while a 10-compartment automatic tool change ensures capacity for virtually any application.

Control on the FlexCNC is simple yet powerful, with conversational and ISO G&M-code programming for versatile 3-axis CNC machining along with an optional 4th axis. Equipped with a color touch screen control, 40 GB of program storage, and 50 programmable zero points. Programs can be loaded through USB or through and ethernet connection. Extensive training is provided, both in-plant and on-site.

Built in the Wapakoneta, OH factory, the G-series 20-06 SE sells for $258,995. Leadtime for these standard machines is just 12-16 weeks. Delivery, installation, training, and two-year warranty available for just $9500. In addition to standard models, FlexCNC can customize a machine to suit specific parameters – including length and width, raised gantry, open machine bed, and double fourth axis.

FlexCNC

705 Commerce Drive

Wapakoneta, OH 45895-9239

P: (800) 837-2503