By 2032 more alternative drive systems than pure combustion engines could be licensed in the passenger car market, according to a new study by Deloitte. It is easy to imagine what this development will mean for the automotive industry: The value-added share of combustion engine components is declining and the share of “electric” drive components is rising just as quickly – including many rotationally symmetrical parts for which mechanical engineering specialists such as EMAG are currently developing precisely tailored production solutions.

Currently, a fully automated and efficient complete solution for the production of rotor shafts as well as the high-precision overturning of the rotor-sheet package has been developed for a supplier group. With the flexible systems, the customer can cover a large portfolio of machining operations. Those responsible are highly satisfied with component quality and reproducibility.

The increasing quantities of e-motors are challenging production planners: In many application areas, they have to establish new solutions with which components, such as the e-motor drive shaft, can be manufactured faster and more efficiently – and with holistic production systems. A new and impressive example at a supplier company that produces components for e-mobility shows how a solution like this can look. How did the collaboration come about?

“Our contact partners were looking for a highly flexible system, including smart automation solutions and IoT integration, to cover a large number of machining operations around the rotor shaft. When faced with such an issue, the customer has relied on EMAG for many years because we offer turnkey solutions from a single source and the EMAG Group masters almost all machining technologies,” explains Andreas Bucher, Key Account Manager at EMAG.

The collaboration began very early on: the customer even shared the design drawings of the component with EMAG in advance, in order to facilitate the subsequent mechanical engineering and enable the leanest and most reliable production process possible. The development of the entire line took place through close contact, as Michael Ihring of EMAG Systems confirms: “At EMAG, the principle of ‘one face to the customer’ always applies. An experienced contact person discusses the requirements of the entire production solution with the customer – this also includes, for example, the machines that do not come from EMAG. Therefore, we still take care of the complete production solution and define its specifications. The advantages are obvious: significantly fewer interface reconciliations shorten the delivery time and also lead to a more favorable and effective overall solution.”

Reaching The Goal In Twelve Operations

The end result now shows an impressive sequence around the rotor shaft – with no less than twelve main and various secondary operations. The automation and interlinking of the individual machines and stations will be carried out with robots, gantry systems and EMAG’s own TrackMotion system.

This process is laid out here, in detail:

- After the operator has fed in the raw parts on buffer belts, rough turning starts on two VTC 200s from EMAG – a perfect solution for 4-axis shaft machining with reduced main times Blow-off and measuring processes follow. The measuring machine gives feedback to the lathes, which then carry out any corrections automatically.

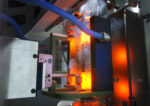

- After the internal gear cutting process the rotor shaft bearing seats are induction heated and hardened in OP 40 on a MIND L 1000 from EMAG eldec.

- The next operations performed on two VTC 200 CD and two VTC 200 from EMAG are also interesting. Both processes are carried out in parallel on two machines in order to increase output. The rotor shaft is then blown off a second time, measured, and the good parts are described with a DMC.

- In OP 70, two assembly processes take place, with a sleeve and a lid being joined.

- A final turning operation by VTC 200 perfects the collar and seats of the rotor shaft. Blowing-off, measuring, and stacking complete the line.

“We see our plans confirmed,” sums up Michael Ihring. “The processes are very stable, which is reflected in the component quality. At the same time, the customer benefits from a flexible cell solution that could be expanded at any time to meet increasing capacity requirements. This flexibility is evident in every detail, right down to the automation. In addition, various intelligent mold change strategies ensure that there are very few downtimes.”

Scroll-free turning ensures perfect sheet package surface finish However, this is not the end of EMAG’s major e-mobility project for this customer, because the machine builders have also designed a solution for high-precision overturning of the rotor-sheet package using the VTC 200 machine. The so-called scroll-free turning process is used: here, a rolling motion of the tool takes place on the workpiece – an obliquely set CBN cutting edge moves over the rotating workpiece.

The cutting edge engagement point moves on continuously. The whole process is around five to six times faster than conventional hard turning and up to three times faster than grinding. Despite this, the result is excellent quality without twist. In other words, surfaces that previously had to be ground can thus be peel turned in the future. This is an ideal solution for the stack of sheets surrounding the shaft.

Bringing Advantages To The Growing E-Mobility Market

“Overall, the customer benefits from perfectly adjusted systems that exhibit high stability and process reliability, both when machining the rotor shaft and when turning the sheet package. These are enormous advantages that we intend to bring to the growing e-mobility market in the coming years,” says Andreas Bucher. “Inquiries from the electric motor manufacturing sector are increasing significantly. At the same time, our technology is already in use in very many application areas in the industry today.