The statistics of confined space inspection and related injuries and fatalities continues to present a revealing truth. Around 2.1 million workers enter such spaces annually and, even with increased health and safety measures, the death toll of such activities remains unacceptably high. By far the biggest reason for such an activity is to carry out routine maintenance.

Drone technology presents a unique method by which such tasks can be performed without the need to put human life at risk. While this might not have been the case a decade, or even five years ago, rapid advances to create unique solutions that can cope with the challenges of confined space inspection is a reality today.

So why do the injury and death figures continue to mount up? One reason is, perhaps, a historical reluctance to embrace cutting-edge technology. Industries, such as mining, oil and gas and petrochemicals are, understandably, hesitant to change accepted methods of inspection for fear of the unknown.

However, with the dawn of a new era of drones and inspection equipment, each day this continues really does cost lives. Why Use Drones? In the United States alone, there’s around two deaths per week involving the inspection of confined spaces. In Australia, the figure is a little over one per week. The main causes of death are listed as:

However, with the dawn of a new era of drones and inspection equipment, each day this continues really does cost lives. Why Use Drones? In the United States alone, there’s around two deaths per week involving the inspection of confined spaces. In Australia, the figure is a little over one per week. The main causes of death are listed as:

Asphyxiation

Poisoning

Engulfment

Oxygen deficiency

Drowning

Explosion

Electrocution

This makes for pretty grim reading and only serves to accentuate why industries must look elsewhere for effective confined space inspection solutions. The greatest advantage of using drones is, of course, to reduce accidents and fatalities. Such machines are impervious to toxic gases and non-oxygen atmospheres. Neither do they require scaffolding or rope systems to be erected.

But there are many other reasons to replace human inspection with that of drones.

Drones can access areas humans can’t:

They can cross gaps, enter narrow channels and get in close proximity to hazardous areas

Drones don’t require total shutdowns:

Drone inspections can, in many cases, take place without disrupting day-to-day operations

Drone inspection removes human error:

Even the best of inspection operatives can’t be guaranteed to provide 100% reliable data all of the time

Drone inspection is faster:

They move quicker and collect more data in a shorter amount of time All of the above combine to make a more cost-effective and far safer solution to confined space inspection.

Real-Time Examples of Drone Technology in Use Today

Real-Time Examples of Drone Technology in Use Today

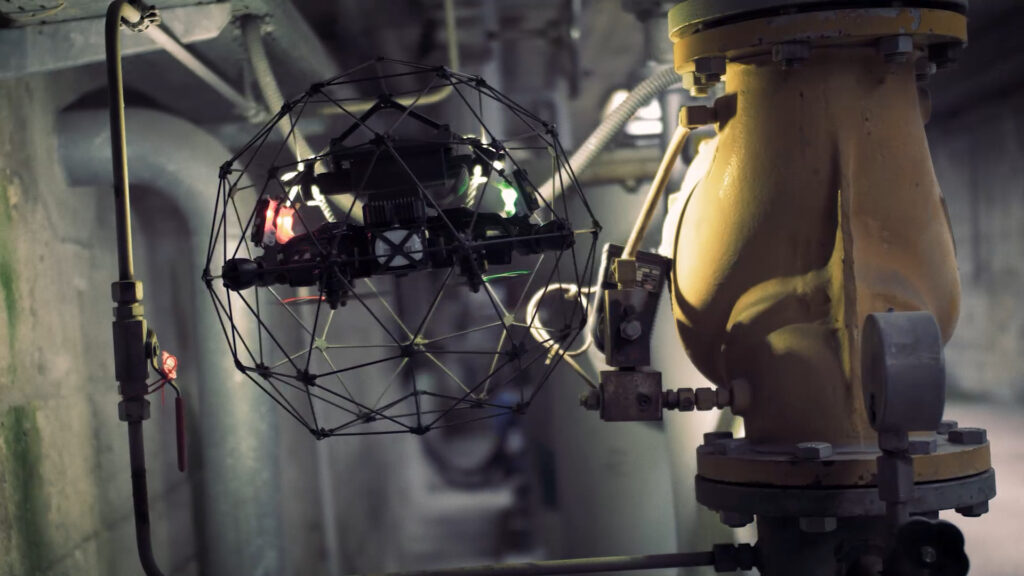

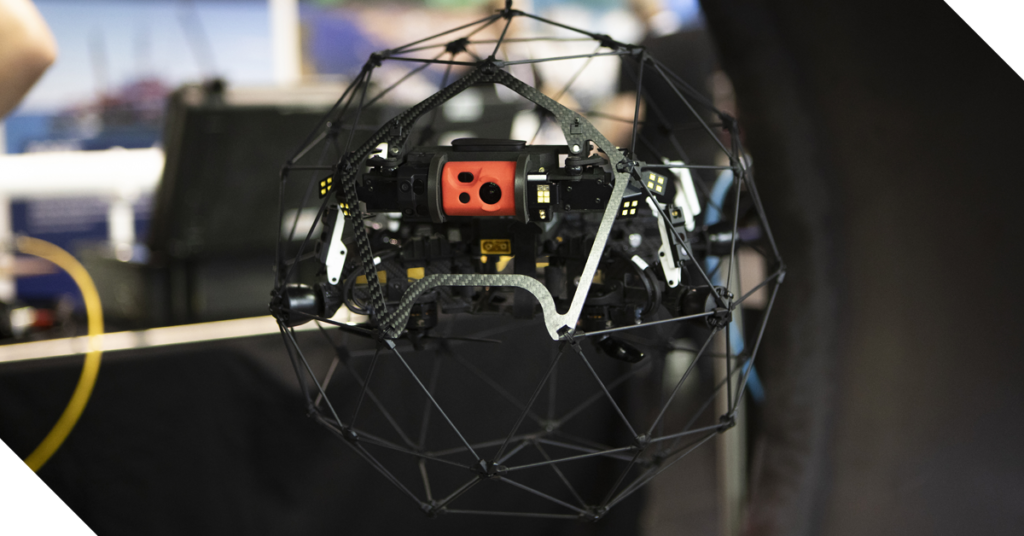

There’s no denying that it’s taken a while to get to where we are today. One notable drone that’s making waves in the industry is the Elios. The brainchild of Adrian Birod and Patrick Thévos from Flyability, the invention was awarded the 2015 UAE Drones for Good Award and a prize of USD $1 million. The original model has since evolved, and the Elios 2 is successfully being utilized around the globe.

Creating a drone that could effectively maneuver within enclosed spaces was certainly a challenge. No GPS signal, with atmospheric aspects, including lack of light, dust and multiple obstacles were just some to overcome. Add in the issue of remote control without a direct line of sight and you begin to realize quite how ambitious the task was.

The first model was enclosed in a cage to absorb the inevitable impacts – one that could turn and roll independently of the drone it protected. But with the Elios 2, the addition of sensors allows the drone to detect obstacles around it, as well as reversible motors to enable rapid direction changes. These, combined with cutting-edge software, prevents collisions and ensures stability during the flight. Inspection capabilities are enhanced, thanks to a 4K camera, thermal camera and the most powerful lighting system ever built onto a commercial drone. The advantages of such drone inspections are clear. Despite the hesitancy of industries to utilize such technological advances, it’s clear that the time is ripe for change. In a world where robotics can truly make a difference to deadly workplace incidents, it’s high time that those entrusted with making responsible choices consider every option available. Tools such as the Elios 2 will, undoubtedly, continue to evolve for the better. Other options will also come to light. Mitigating risk, lowering costs and improving inspection data is surely a reason to explore the art of the possible. Partnering with a forward-thinking equipment provider is by far the ultimate method of doing this – something that Perth-based provider, Nexxis, prides itself in the delivery of.