Press Brake Safety, originally operating under the name of Advanced Manufacturing Solutions, LLC., was founded in 2001 by Douglas Boyer, Jr. who had over 25 years of experience working at Hurco Companies, a major US machine tool builder. In the years thereafter, Doug continued to sell industrial metal working equipment while struggling through a nationwide major downturn in manufacturing after the 9-11 attack. During this time, Doug met Gotz Fiessler and started developing contacts and techniques to promote the Fiessler European line of industrial safety devices in North America. Their retrofittable AKAS line of press brake safety lasers became quite popular. Soon customers were ordering the retrofits avoiding OSHA fines without having to replace costly machines to keep operators safe.

Press Brake Safety, originally operating under the name of Advanced Manufacturing Solutions, LLC., was founded in 2001 by Douglas Boyer, Jr. who had over 25 years of experience working at Hurco Companies, a major US machine tool builder. In the years thereafter, Doug continued to sell industrial metal working equipment while struggling through a nationwide major downturn in manufacturing after the 9-11 attack. During this time, Doug met Gotz Fiessler and started developing contacts and techniques to promote the Fiessler European line of industrial safety devices in North America. Their retrofittable AKAS line of press brake safety lasers became quite popular. Soon customers were ordering the retrofits avoiding OSHA fines without having to replace costly machines to keep operators safe.

This business has continued to grow so much that a service company started in 2014 now provides the customer base with North America repair support, staffed with factory certified technicians. The Service group is headed up by Bruce Meyer, an industry seasoned professional and newcomer Andrew Litton, an excellent technician.

The sales company’s name was changed to Press Brake Safety, more adequately defining their relationship with their major product line of safety equipment for press brakes. Joining the family business in 2013 and taking on the leadership role, Jason Boyer came on board, and as President of the company, now oversees the sales and marketing. Another addition to the team was Kimberly Gregonis-Boyer who is the Chief Financial Officer of Press Brake Safety. Since day one, their mission was to be a full-service safety product provider, offering solutions to the industrial sector throughout North America.

The sales company’s name was changed to Press Brake Safety, more adequately defining their relationship with their major product line of safety equipment for press brakes. Joining the family business in 2013 and taking on the leadership role, Jason Boyer came on board, and as President of the company, now oversees the sales and marketing. Another addition to the team was Kimberly Gregonis-Boyer who is the Chief Financial Officer of Press Brake Safety. Since day one, their mission was to be a full-service safety product provider, offering solutions to the industrial sector throughout North America.

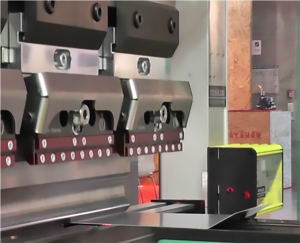

First Co-Moving Press Brake Safety System

Modern press brakes are characterized by high productivity and precision. Due to the higher stroke rate during work speed, considerably more workpieces can be manufactured in the same period. New press brakes have to be equipped by a safety system that provides the operators with a reliable protection from squeezing, crushing or shearing of fingers, hands and arms. Protective systems for the press brakes should be designed in a way that, on the one hand, the operator who is working within the bending area of the press is protected in all situations, and on the other hand, the productivity of the staff and the machine is not restricted. One needs to consider the primary goal is the protection of personal health and life and is a priority over profit.

The Fiessler AKAS 3-P is the first co-moving press brake safety system worldwide that provides high-speed operation up to the clamp point. The new AKAS 3-P, designed for the OEM manufacturers, features top-level productivity while providing maximum safety at the same time. When using this press brake safety system, there is no loss in productivity. On modern press brakes, the closing movement, which is in high speed until the clamp point during regular bending, is provided by this safety system. During the entire closing movement, the operator’s hand or fingers are protected from being squeezed between two opposed moving machine parts by the presence of the three-dimensional safety laser beam grid that is located beneath the ram. The system provides full safety during regular bending and box-bending modes.

The Fiessler AKAS 3-P is the first co-moving press brake safety system worldwide that provides high-speed operation up to the clamp point. The new AKAS 3-P, designed for the OEM manufacturers, features top-level productivity while providing maximum safety at the same time. When using this press brake safety system, there is no loss in productivity. On modern press brakes, the closing movement, which is in high speed until the clamp point during regular bending, is provided by this safety system. During the entire closing movement, the operator’s hand or fingers are protected from being squeezed between two opposed moving machine parts by the presence of the three-dimensional safety laser beam grid that is located beneath the ram. The system provides full safety during regular bending and box-bending modes.

In order to provide the required adjustment after a tool change using upper tools with different tool sizes without any loss of time, the AKAS 3-P transmitters and receivers come with fully-automatically moving supports. The adjusting procedure is done by a simple push of the adjustment start button. The time that is otherwise required to adjust the unit is saved and can be used for other procedures such as material handling or programming the machine parameters.

In order to provide the required adjustment after a tool change using upper tools with different tool sizes without any loss of time, the AKAS 3-P transmitters and receivers come with fully-automatically moving supports. The adjusting procedure is done by a simple push of the adjustment start button. The time that is otherwise required to adjust the unit is saved and can be used for other procedures such as material handling or programming the machine parameters.

The AKAS 3-P is TUV CE type approved/cUL listed and complies with the standards of the B11.3, EN12622, Z142 and NR12.

About Press Brake Safety

Press Brake Safety, headquartered in Zionsville, Indiana has supplied metalworking machinery throughout the U.S. and Canada for 19 years and is a leading industry advocate for press brake operator safety. PBS is the exclusive North American installer of Germany-based Fiessler AKAS® laser safety systems, the most sophisticated press brake safety systems in the world, and provides complete maintenance, service and training to users. As the industry tries to balance profitability, operator safety and regulators’ capabilities to effectively audit operators’ practices, Press Brake Safety can help you protect your workers and your bottom line.

Press Brake Safety

P: (800) 901-1193