So how did Soft Robotics and this gripping technology come into being?

So how did Soft Robotics and this gripping technology come into being?

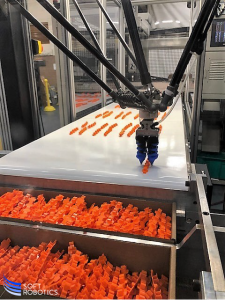

A chemist at Harvard University, Dr. George Whitesides, was intrigued by the skill and agility with which octopi used their tentacles to manipulate a wide variety of objects of different sizes and material consistencies, automatically adjusting its grip pressure and tentacle configuration. He was able to partner with the Department of Defense to develop the technology. Our CEO, Carl Vause, learned of this work and immediately saw how valuable it would be for manufacturing and packaging applications. So it was agreed that Soft Robotics would be formed and stand as the go-to-market representative for this gripper technology.

What were the first markets to understand this product’s potential?

Automotive was the first industry to realize the potential of traditional automation since they have so many consistent processes and products that are readily automated. Traditional gripper design works well with consistent part geometries, but it didn’t translate to industries where there is natural variation in products or a very high mix of low-volume SKUs. Having to change a gripper each time the SKU changes is time-consuming and costly. The Soft Robotics gripper enables the automation of industries that have products with variation, that are delicate in nature, or have stringent surface finish requirements. Developing relationships with companies such as FANUC and ABB, who also became investors, has been valuable, and that list has grown much longer over time. This allowed us access to their global trade channels in a wide variety of markets.

Are your grippers compatible with different types and makes of robots and cobots?

Are your grippers compatible with different types and makes of robots and cobots?

We describe ourselves as being “robot agnostic” so that the grippers can be paired with virtually any type or brand of robot. Because of our relationship with companies like FANUC and Universal Robots, we’ve developed specific control systems that integrate with their platforms to allow gripper manipulation directly from the teach pendant. Plus, our grippers can be configured to match just about any OEM’s robotic arm. Our mGrip adaptable system includes both the gripper and a controller. In fact, our controller system is central to the gripper’s ability to automatically adjust to different types of parts without halting production, and with no additional reprogramming required. This is also ideal for operations that produce small lots since the gripper automatically adjusts to part changes without the need for sensors or an expensive vision system. This allows our grippers to reconfigure to pick up anything from a loaf of bread to large, heavy parts and materials. We even have a demonstration for our cobot controllers, where someone puts their hand in the gripper and actually feels how it regulates its grip pressure according to what it’s holding, providing a delicate but secure grip.

This technology seems ideal for cobots working in proximity to human operators.

This technology seems ideal for cobots working in proximity to human operators.

Absolutely, which is completely intentional. As cobot technology evolves, our grippers enable adoption throughout any manufacturing or packaging process. There are the ergonomic benefits I’ve mentioned, along with meeting safety concerns involving human/cobot interaction. Our soft fingers eliminate pinch points, providing what we feel is the safest gripper available for collaborative robots, where safety is of paramount importance.

Tell us about the services you offer to your customers.

We have a dedicated sales team, knowledgeable application engineers, and every type of engineer you can imagine, We’re prepared for whatever challenge an end-user might encounter. Besides service and maintenance assistance, these professionals also provide consultation to customers as they choose the ideal type of gripper system for their particular application. So our relationship with our customers is in-depth and ongoing. And we’re really proud of the fact that our technology helps keep the supply chain functioning smoothly, especially during times such as these when we’re dealing with issues like coronavirus exposure in the workplace. We are constantly adapting to the evolving nature of robot/cobot developments.