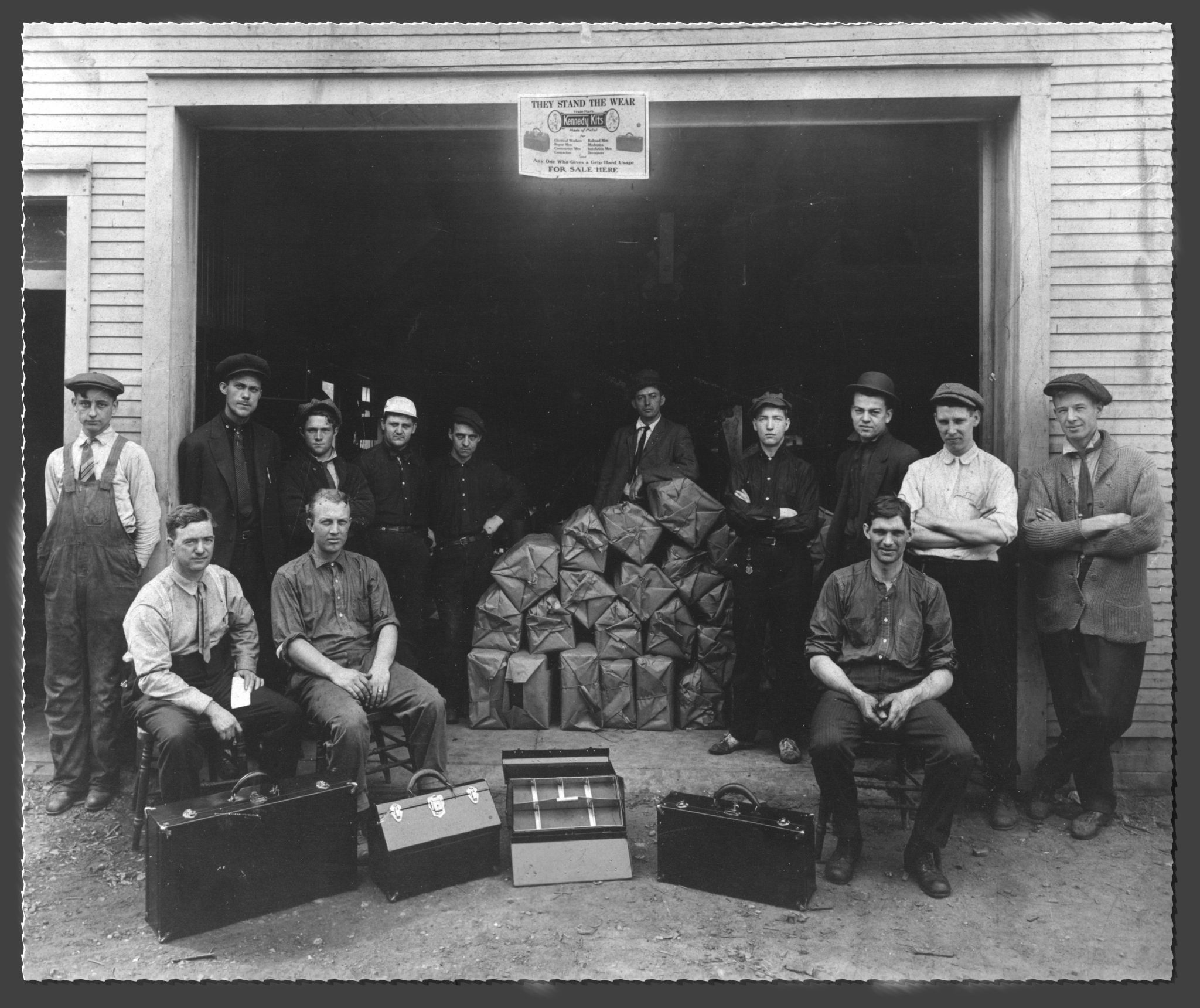

In 1911, Howard Kennedy recognized a problem. Working as an engineer on the Pennsylvania Railroad in Fort Wayne, Indiana wasn’t easy work. On top of the hardships and often dangerous labor that he and other workers faced, there was also the need to maintain, store, and protect the tools and gear used on a daily basis. At this time, standard leather suitcases were the norm, but did not adequately protect from the rigors of railroad travel.

“Howard Kennedy was discouraged by his and colleagues’ belongings, tools, and instrumentation getting ruined or misplaced,” explains Shannon Mason, sales operations manager of Kennedy.

“Howard Kennedy was discouraged by his and colleagues’ belongings, tools, and instrumentation getting ruined or misplaced,” explains Shannon Mason, sales operations manager of Kennedy.

From a small garage, Kennedy designed his own metal suitcase for himself out of galvanized sheet metal. This was the birth of what would become the foundation of Kennedy tool storage equipment products. Two years later, Kennedy relocated to Van Wert, Ohio. To this day, Kennedy has been proudly manufacturing many of their industrial grade steel tool chests, roller cabinets, side cabinets and visual tool control right here in the United States. Their products can be found in use by MRO and metalworking professionals in the aerospace, automotive, construction, energy, fleet maintenance, medical/pharmaceutical industries.

Features of Kennedy’s popular Signature Series Machinists’ and Mechanics’ Chest include a high security tubular locking system, heavy-duty friction drawer slides, drop front panel that conceals and secures, and hand felted, wool-lined drawers that protect precision tools. The friction drawer slides set Kennedy apart from most tool storage system manufacturers that utilize ball bearings. This is especially important for end users who may be restricted from utilizing products that contain ball bearings, such as in the aerospace manufacturers like Boeing and Delta.

Features of Kennedy’s popular Signature Series Machinists’ and Mechanics’ Chest include a high security tubular locking system, heavy-duty friction drawer slides, drop front panel that conceals and secures, and hand felted, wool-lined drawers that protect precision tools. The friction drawer slides set Kennedy apart from most tool storage system manufacturers that utilize ball bearings. This is especially important for end users who may be restricted from utilizing products that contain ball bearings, such as in the aerospace manufacturers like Boeing and Delta.

Kennedy recognizes that the importance of supporting the future of manufacturing. Recently, the company donated three complete combination units to Lanier Tech in Georgia, which had expanded their facility with a new CNC machine shop. Lanier Tech offers precision machining and manufacturing programs that give students the training and opportunities they need to excel in the machining and metalworking world.

“In the last 15 years, we have lost a lot of manufacturing in this country, and the hardest hit part of that was the machinist world,” says Craig Martin, vice president of sales and marketing for Kennedy. “The only way it can come back is have the people to support it and get back into the trade.”

“In the last 15 years, we have lost a lot of manufacturing in this country, and the hardest hit part of that was the machinist world,” says Craig Martin, vice president of sales and marketing for Kennedy. “The only way it can come back is have the people to support it and get back into the trade.”